Tunnel secondary lining construction process monitoring system

A technology for secondary lining and process monitoring, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of insufficient strength, irregular vibration, honeycomb construction quality of secondary lining, etc., to avoid irregular maintenance and avoid vibration. The effect of tamping irregularities and avoiding concrete segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

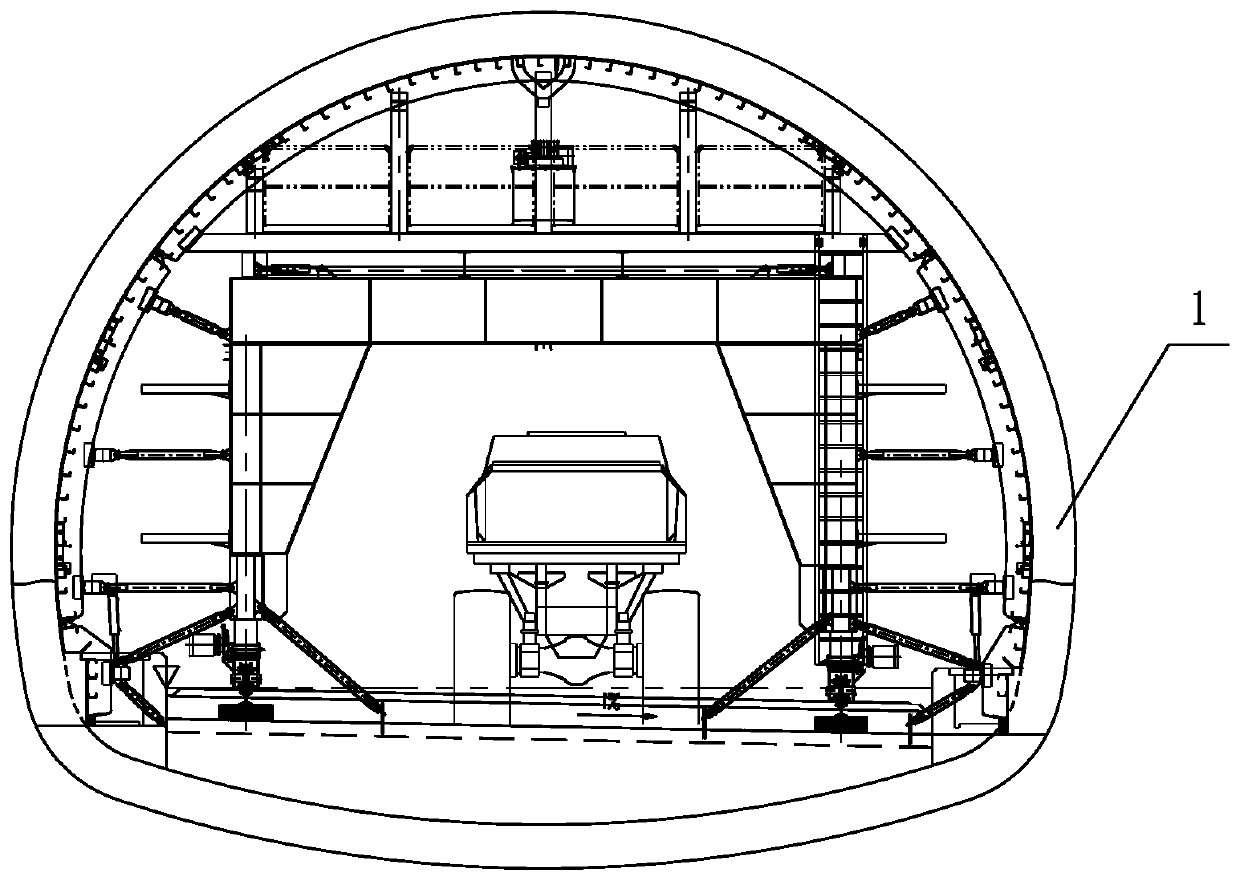

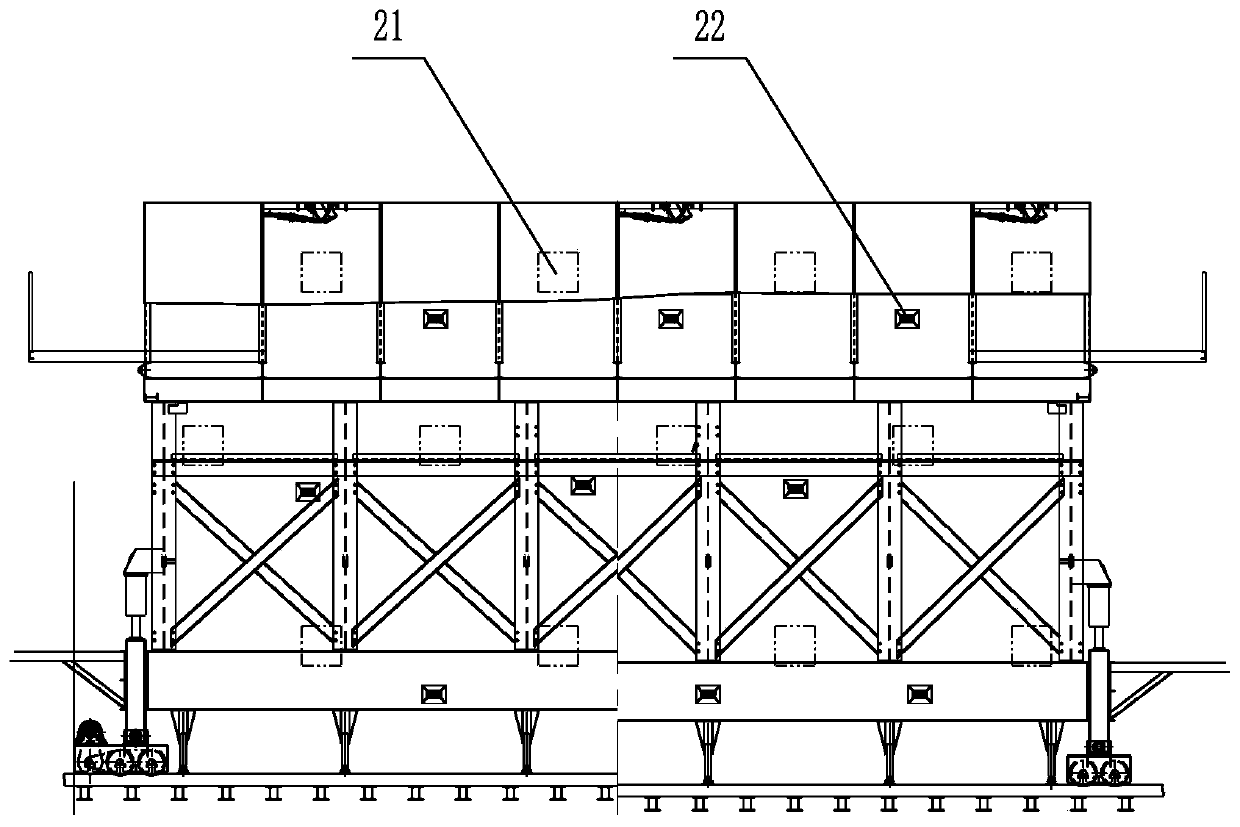

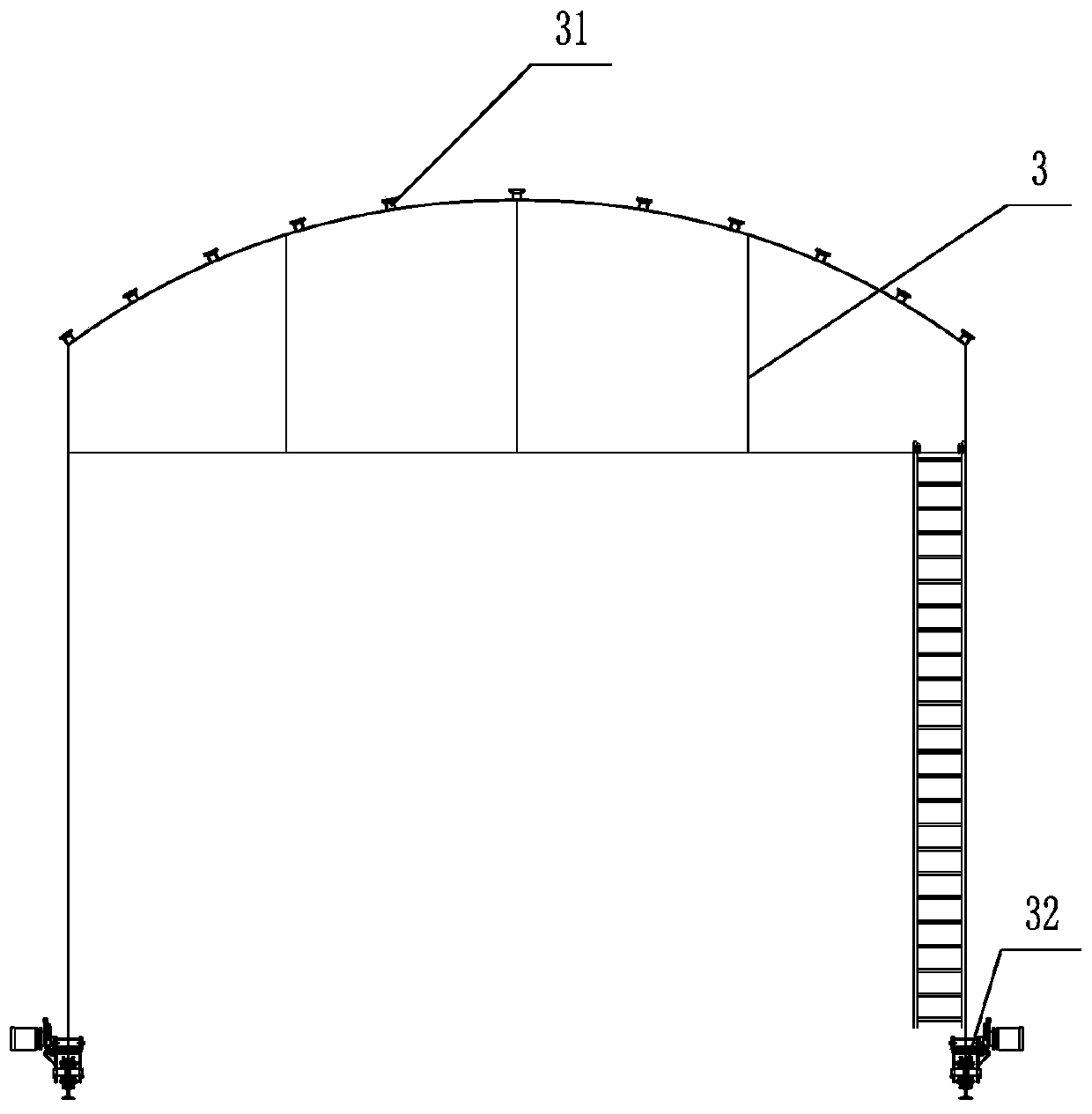

[0024] Such as figure 1 and figure 2 As shown, the secondary lining trolley is a special equipment that must be used in the secondary lining of the tunnel construction process. It is used for the concrete lining construction of the inner wall of the tunnel. A vibrator 22 is attached. During specific construction, the concrete pumping device 10 is connected to the pumping port 21 first. A concrete bin 1 that needs to be filled with concrete is formed between the formwork of the secondary lining trolley and the tunnel. In order to better fill the concrete, the existing technology usually divides it into layers.

[0025] Such as Figure 5 As shown, the tunnel secondary lining construction process monitoring system provided in this embodiment includes a sensor A5, a sensor B6, a sensor C7, a display terminal 8 and a radio frequency module.

[0026] The sensor A5 is installed on the secondary lining trolley to monitor whether there is concrete flowing through the concrete. Bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com