Electromagnetic shielding encapsulation method and encapsulation structure

A technology of electromagnetic shielding and packaging method, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of high integration, product reliability and performance impact, and void phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

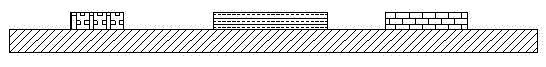

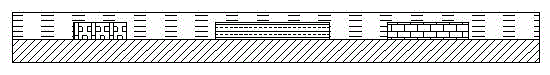

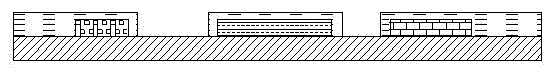

[0038] see Figure 7 , an electromagnetic shielding packaging structure of the present invention, it includes a substrate 1, a radio frequency chip 2, a first electronic device 3 and a second electronic device 4 are mounted on the front of the substrate 1, the radio frequency chip 2, the first electronic device 3 And the second electronic device 4 is covered with a layer of dry film 5, the dry film 5 area around the radio frequency chip 2 is opened with a filling groove 6 through exposure and development, and the filling material 6 is filled with metal fillers 7, the metal fillers The upper surface of 7 is flush with the upper surface of dry film 5, and a layer of metal layer 8 is sputtered on the upper surfaces of dry film 5 and metal filler 7, and the metal filler 7 and sputtered metal layer 8 form an electromagnetic shielding structure.

[0039] The metal filler 7 can be replaced by liquid copper or thin metal film.

[0040] Its process method is as follows:

[0041] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com