Roofing eave waterproof structure

A waterproof structure and roofing technology, applied in the direction of roofing, roof covering, building structure, etc., can solve the problems of insufficient rigidity at the cornice, damage to the building's use function, water accumulation, etc., and achieve the effect of avoiding rainwater infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

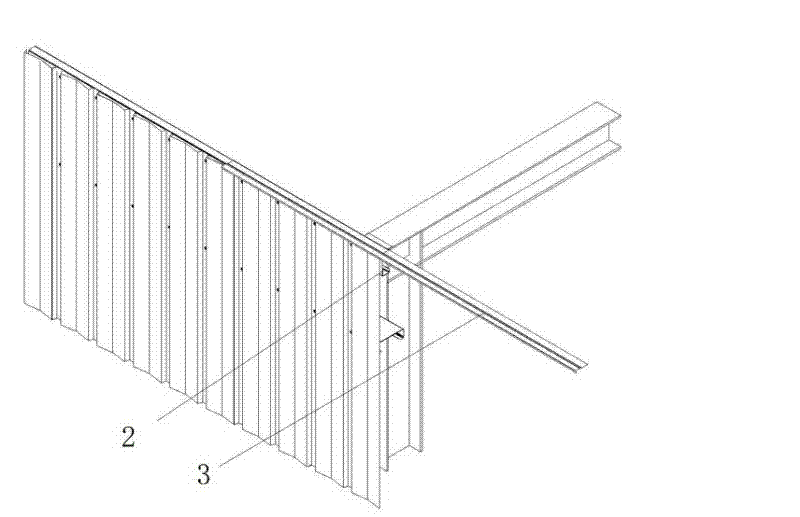

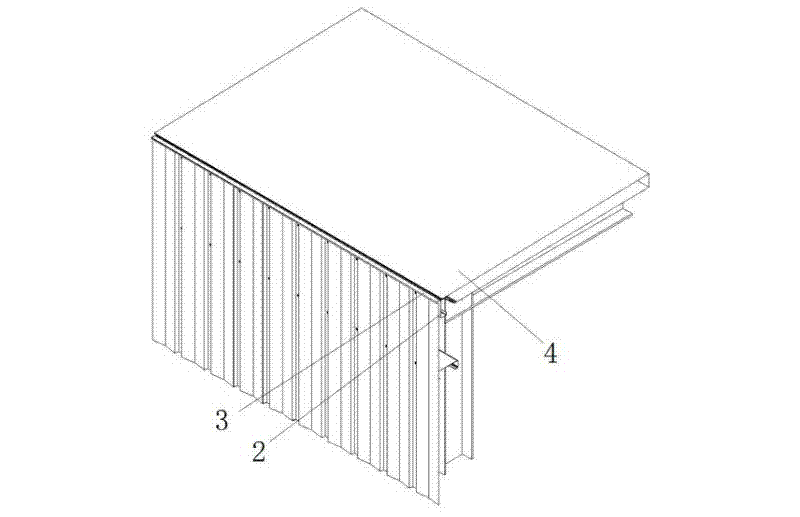

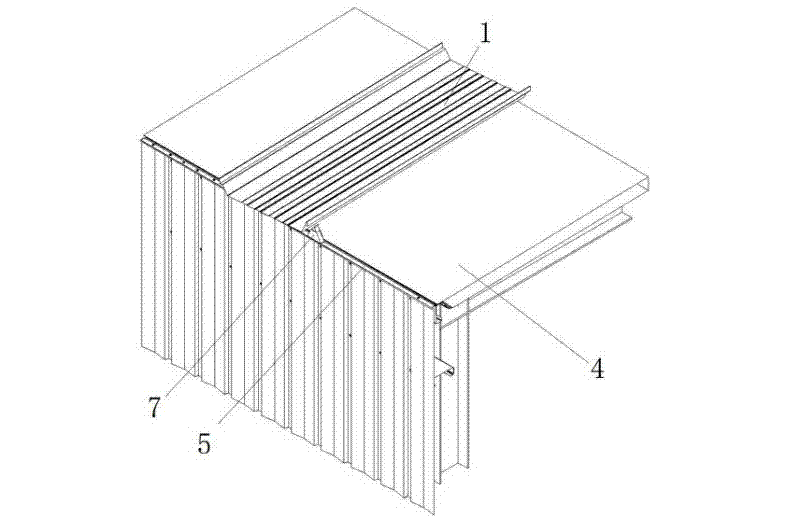

[0021] With reference to the drawings, the preferred embodiments of the present invention will be further described in detail.

[0022] A roof cornice waterproof structure mainly involves components including: roof panel 1, roof cornice purlin 2, cornice support edge 3, roof insulation cotton 4, sealing tape 5, roof fastener 6, and metal inner plug 7.

[0023] The invention is mainly aimed at forming a good connection structure at the junction of the wall panel and the roof panel, which is wind and rainproof.

[0024] Firstly, a cornice supporting edge 3 is set at its junction. The cornice supporting edge 3 is formed by pressing and pressing metal steel, including an inner supporting plate 31 and an outer connecting plate 32. The inner supporting plate 31 is fixed on the existing roof eave purlin 2 of the house itself, and an inclined plane 33 transitions between the outer connecting plate 32 and the inner supporting plate 31, making the outer connecting plate 32 higher than the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com