Ultra-high performance concrete and common concrete combined pile and construction method thereof

An ordinary concrete, ultra-high performance technology, applied in the field of ultra-high performance concrete and ordinary concrete composite piles and their construction, can solve the problems of large cross-section and easy construction quality of cast-in-place piles, and achieve good mechanical properties, good mechanical properties and Economic benefit and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

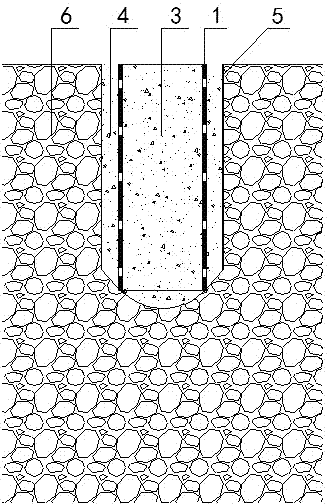

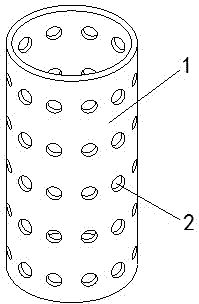

[0024] Such as Figure 1~2 As shown, a composite pile of ultra-high performance concrete and ordinary concrete includes a prefabricated ultra-high performance concrete tube 1, and a plurality of holes 2 uniformly distributed on the side wall of the prefabricated ultra-high performance concrete tube 1 are opened. The high-performance concrete prefabricated cylinder 1 is placed in the pile hole and the center lines of the two coincide. The ultra-high performance concrete prefabricated cylinder 1 is poured with ordinary concrete to form an ordinary concrete inner core 3. The ultra-high performance concrete prefabricated cylinder 1 The outer wall of 1 flows ordinary concrete from the inside to the outside through the hole 2 to form an ordinary concrete bonded outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com