Manufacturing method for COF flexible substrate and capable of avoiding cavities in through holes as well as product thereof

A manufacturing method and flexible substrate technology, which is applied in the direction of printed circuit manufacturing, electrical connection formation of printed components, electrical components, etc., can solve problems such as voids in holes and different copper growth speeds, and achieve the effect of solving the problem of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Follow the steps below to fabricate a COF flexible substrate that avoids voids in vias:

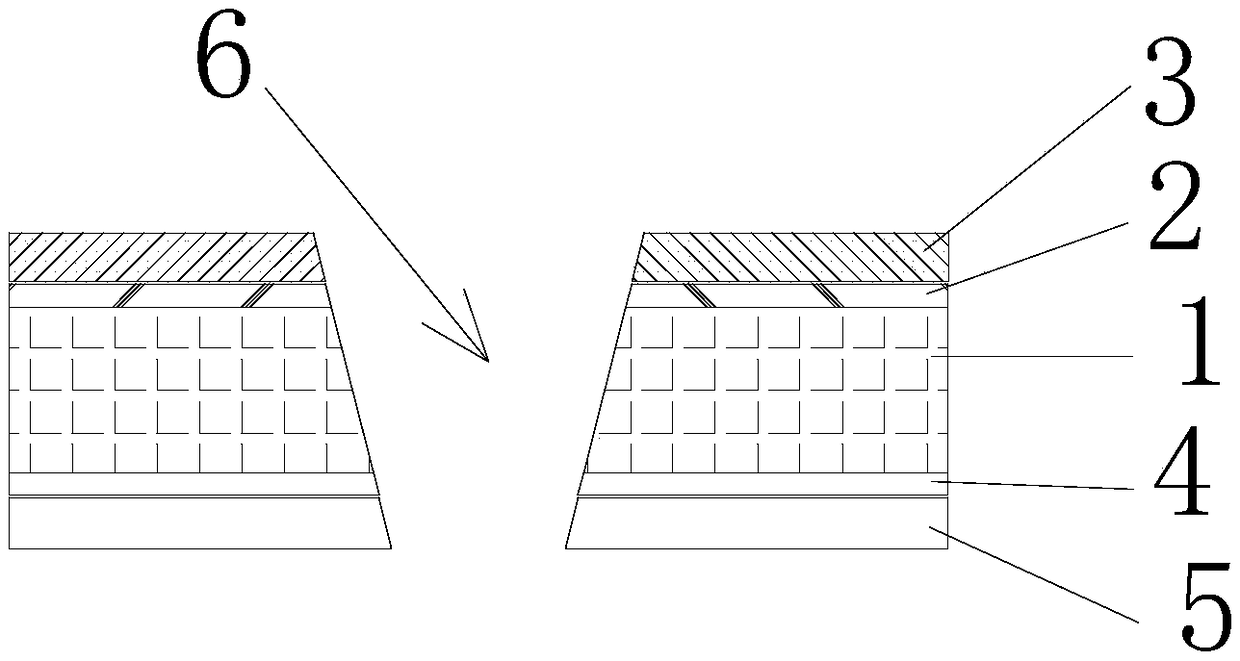

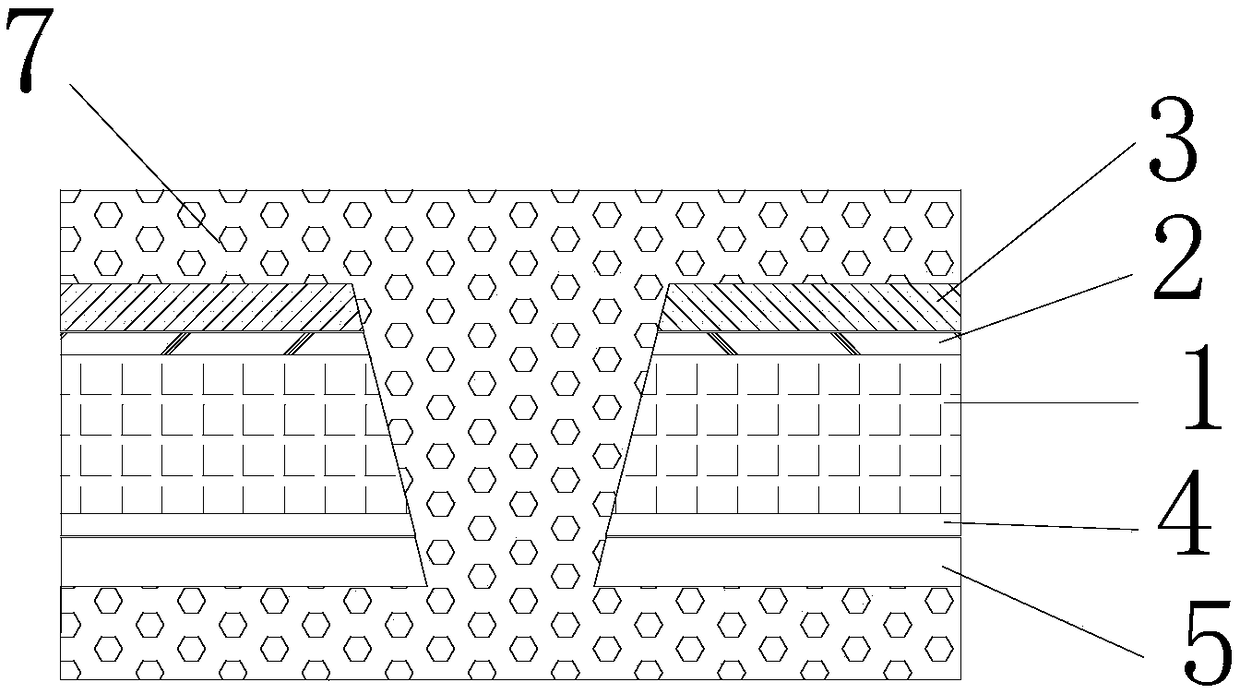

[0024] (1) Laser drilling: on the upper surface of the polyimide intermediate layer 1, an upper metal Ni / Cr layer 2 with a thickness of 20nm is set, and at the lower surface of the polyimide intermediate layer 1, a lower metal Ni with a thickness of 20nm is set. / Cr layer 4, an upper copper layer 3 with a thickness of 1 μm is set on the upper surface of the upper metal Ni / Cr layer 2, and a lower copper layer 5 with a thickness of 1 μm is set on the lower surface of the lower metal Ni / Cr layer 4 to make a base material, On the base material, a through hole 6 that runs through the entire base material is lasered. The laser adopts an impact method, and the number of impacts is 12 times. The upper aperture of the through hole 6 is 25 μm, and the lower aperture of the through hole 6 is 15 μm;

[0025] (2) In-hole coating: deposit a conductive carbon film on the inner wall of the through...

Embodiment 2

[0028] The difference from Example 1 is that in step (1), the number of impacts is 10, and the lower diameter of the through hole 6 is 11 μm.

Embodiment 3

[0030] The difference from Example 1 is that in step (1), the number of impacts is 11, and the lower hole diameter of the through hole 6 is 14 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com