Water-borne rubber cement for cotton canvas rubber shoe foxing bonding and preparation method thereof

The technology of canvas rubber shoes and fence is applied in the field of rubber processing, which can solve the problems of low initial adhesion strength, small final adhesion strength, long processing cycle, etc., and achieves the effect of improving flexural resistance, solving quality problems and ensuring uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

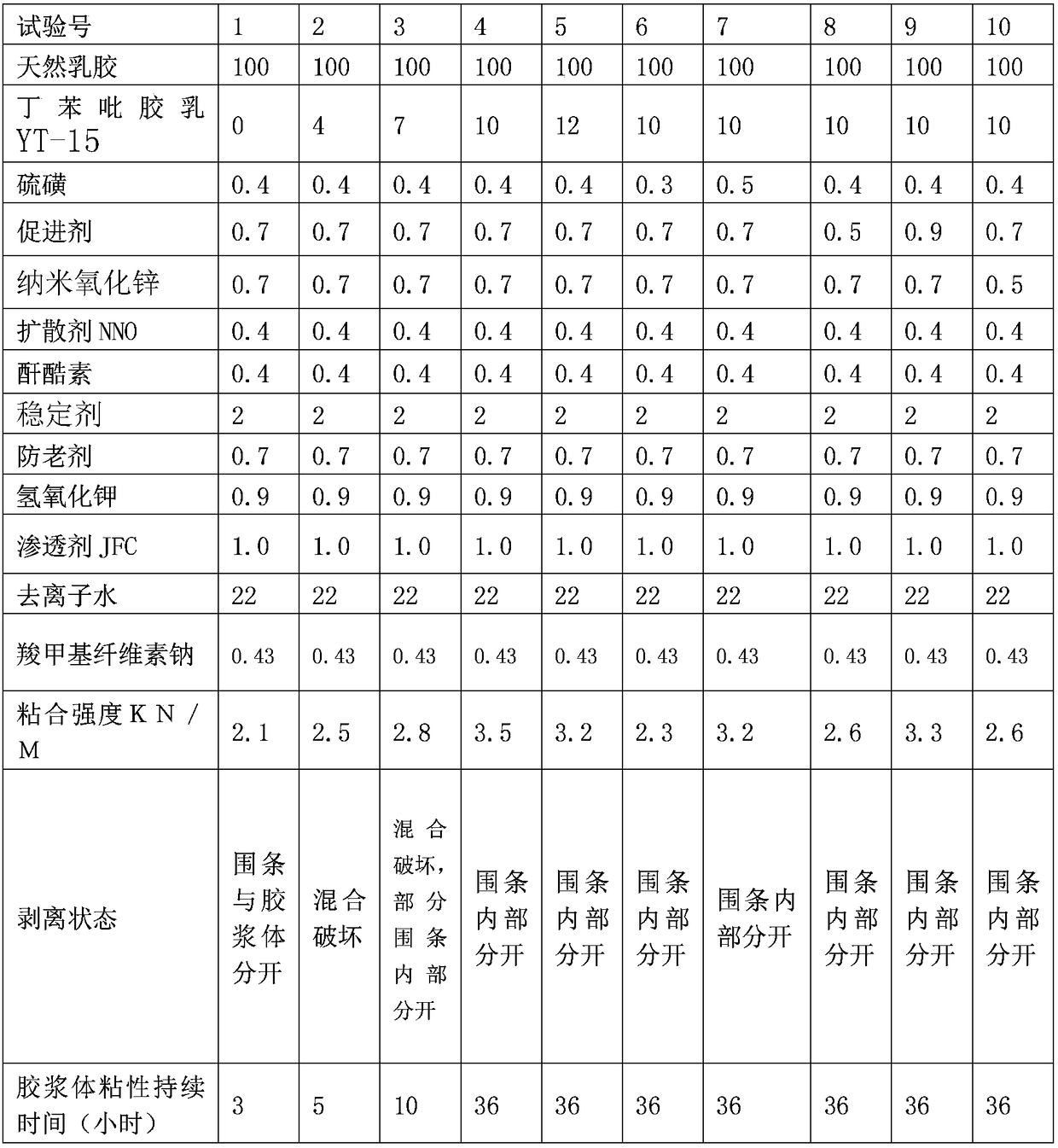

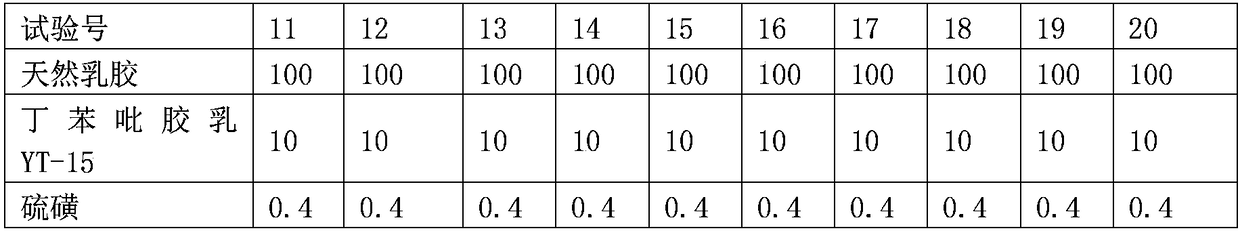

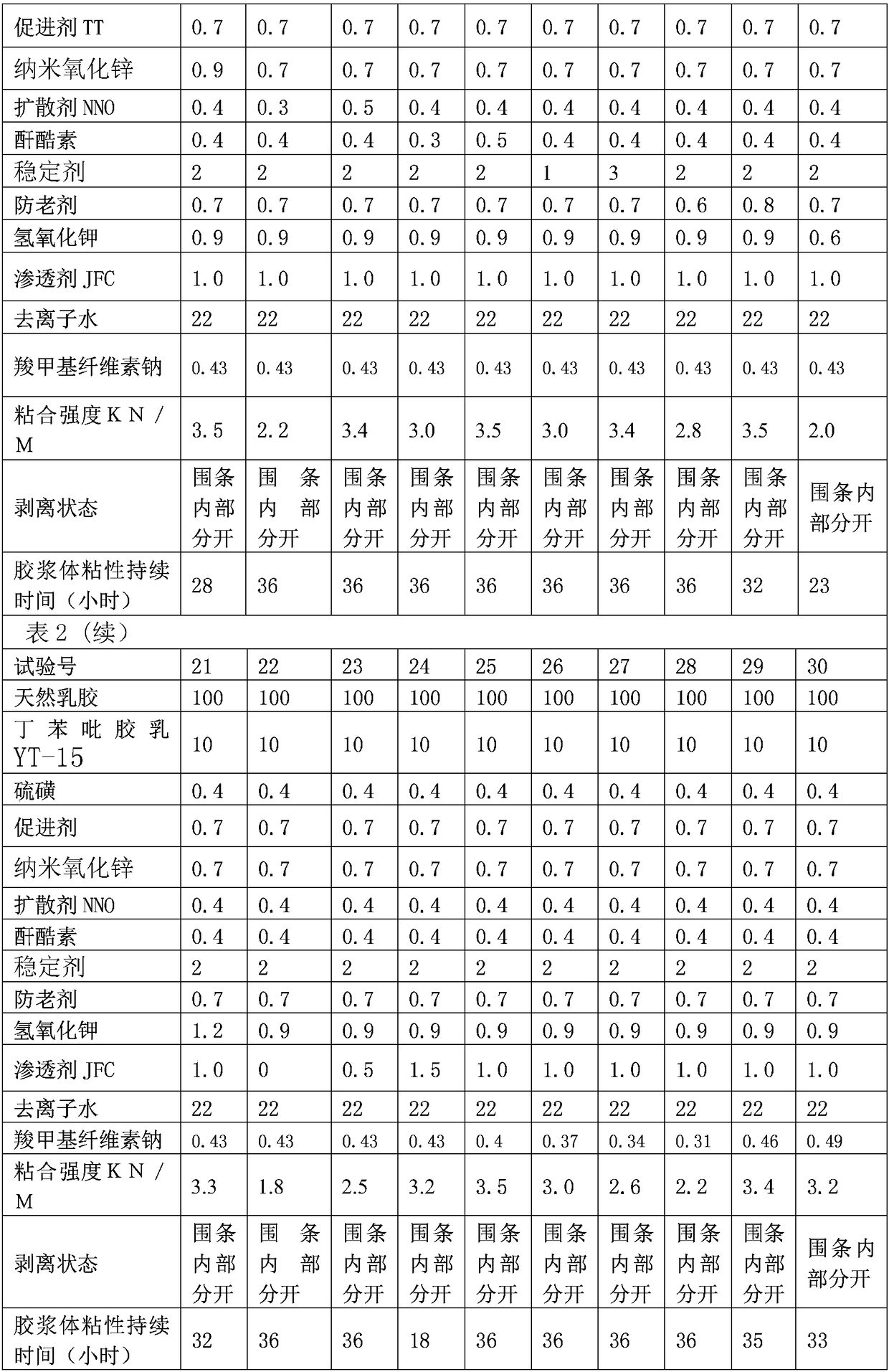

Examples

Embodiment 1

[0073] Embodiment 1 of the present invention: Water-based mucilage for the bonding of cotton canvas rubber shoes enclosures, including 100 kg of natural latex, 10 kg of butylfenpyr latex, 22 kg of deionized water, 0.43 kg of sodium carboxymethyl cellulose, 1.0 kg of penetrant, and sulfur 0.4kg, Accelerator 0.7kg, Nano Zinc Oxide 0.7kg, Diffusion Agent 0.4kg, Anhydride Casein 0.4kg, Stabilizer 2.0kg, Potassium Hydroxide 0.9kg, Antiaging Agent 0.7kg, Antifungal Agent BCM 0.01kg as raw materials .

[0074] The preparation method of the water-based glue glued to the cotton canvas rubber shoes skirt, each component is taken according to the above-mentioned parts by weight;

[0075] 1) Ingredients:

[0076] (1) Add 0.9 kg of potassium hydroxide to 20 kg of deionized water under stirring conditions, stir evenly, and cool to room temperature to obtain 20.9 kg of weak alkaline water.

[0077] (2) The solid material "sulfur 0.4kg, accelerator 0.7kg, nano-zinc oxide 0.7kkg, diffusing a...

Embodiment 2

[0081]Embodiment 2 of the present invention: Water-based mucilage for the bonding of cotton canvas rubber shoes enclosure strips, including 100 kg of natural latex, 10 kg of butylfenpyr latex, 23 kg of deionized water, 0.42 kg of sodium carboxymethyl cellulose, 1.0 kg of penetrant, and sulfur 0.4kg, Accelerator 0.7kg, Nano Zinc Oxide 0.8kg, Diffusion Agent 0.3kg, Anhydride Casein 0.5kg, Stabilizer 2.0kg, Potassium Hydroxide 0.9kg, Antiaging Agent 0.7kg, Antifungal Agent BCM 0.01kg as raw materials .

[0082] The preparation method is the same as in Example 1.

Embodiment 3

[0083] Embodiment 3 of the present invention: Water-based mucilage for the bonding of cotton canvas rubber shoes enclosures, including 100 kg of natural latex, 8 kg of butylfenpyr latex, 23 kg of deionized water, 0.45 kg of sodium carboxymethyl cellulose, 0.8 kg of penetrant, and sulfur 0.4kg, Accelerator 0.8kg, Nano Zinc Oxide 0.7kg, Diffusion Agent 0.3kg, Anhydride Casein 0.4kg, Stabilizer 2.0kg, Potassium Hydroxide 0.9kg, Antiaging Agent 0.6kg, Antifungal Agent BCM 0.01kg as raw materials .

[0084] The preparation method is the same as in Example 1.

[0085] The obtained water-based glue for bonding cotton canvas rubber shoes has high stability, high initial tack and final tack, and realizes synchronous positive vulcanization of the adhesive and the various rubber parts of the shoe, and can be used for cotton canvas fibers. Forms a good bond.

[0086] 7) Use a gluing brush to glue the prepared cotton canvas rubber shoe skirt with water-based glue and brush it on the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com