Anti-disengaging tunnel secondary lining concrete pouring constructing method and formwork system

A secondary lining and concrete technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve problems such as hidden danger of tunnel waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

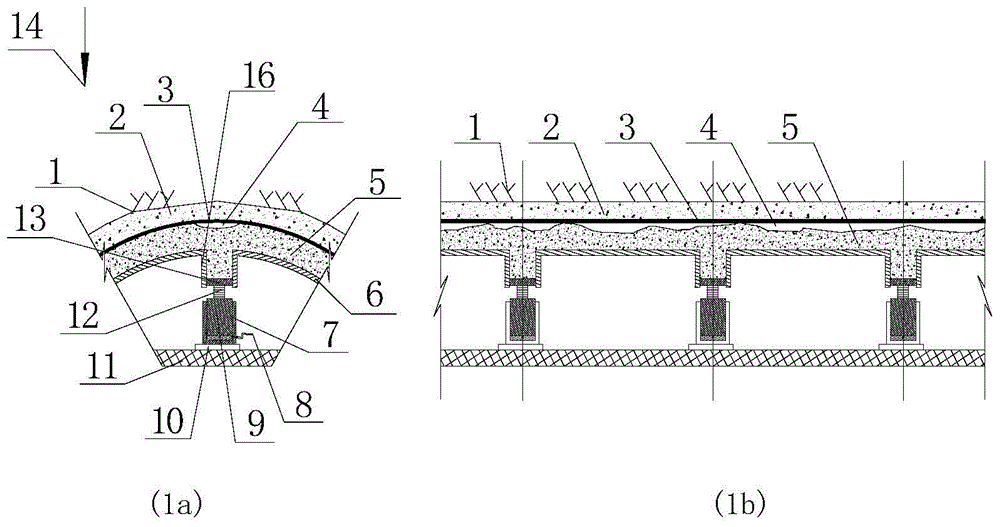

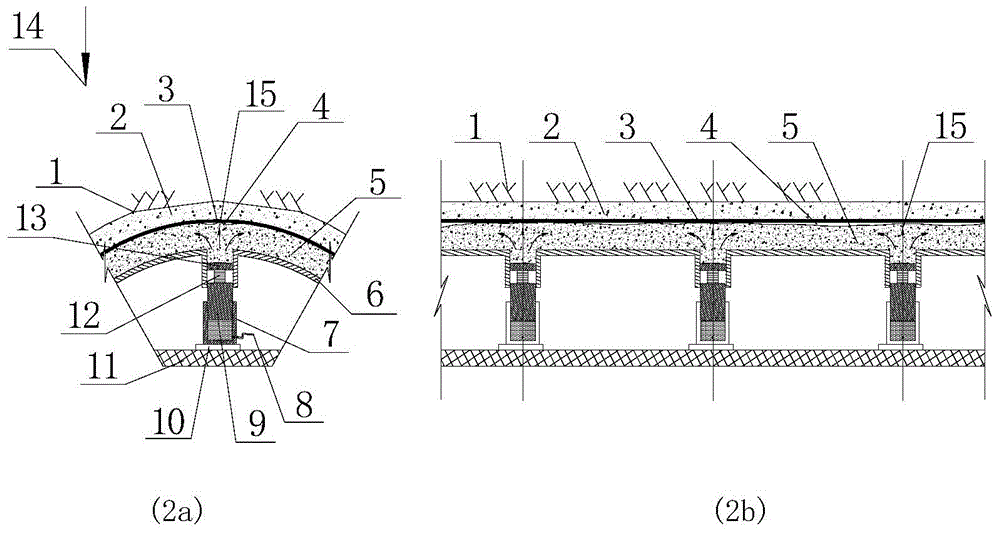

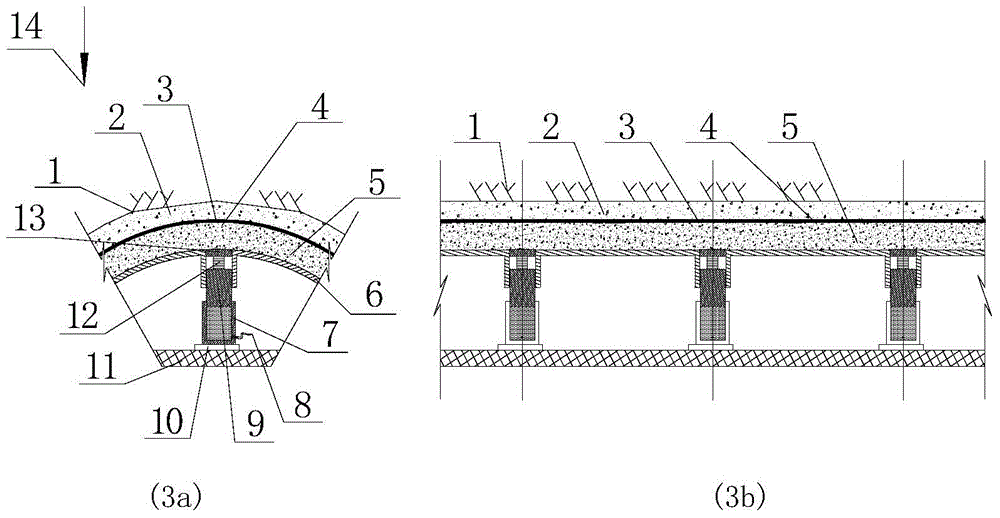

[0013] Such as Figures 1 to 3 As shown, the concrete pouring construction formwork system for the secondary lining of the anti-evacuation tunnel of the present invention includes a formwork and a hydraulic jack 7 . The template has a radian that matches the tunnel design, and circular steel cylinders 16 with inverted protrusions are arranged at intervals along the longitudinal direction of the template to form a T-shaped template 6 . The jack piston 9 of the hydraulic jack is connected to the propulsion piston through the force transmission column. The propulsion piston is removably placed inside the inverted protruding circular steel cylinder. The end of the propulsion piston has a radian matching the formwork to ensure the concrete surface Smooth transition.

[0014] Concrete pouring construction method for the secondary lining of the anti-evacuation tunnel using the aforementioned formwork system

[0015] Use high-strength steel to make the aforementioned T-shaped formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com