Welded aluminum honeycomb light enclosure wall for warship

An aluminum honeycomb and ship technology, applied in the direction of hull bulkheads, hull panels, hull components, etc., can solve the problems of insufficient rigidity of light enclosures, shaking of light enclosures, insufficient strength of light enclosures, etc., and reduce the construction process. and materials, lower construction costs, good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

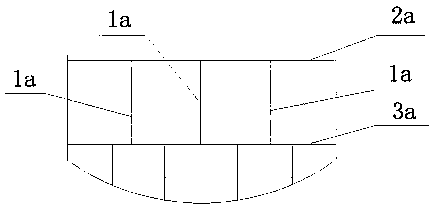

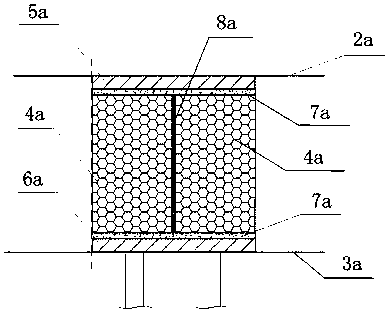

[0038] Example 1, such as Figure 1 to Figure 4 As shown, a welded aluminum honeycomb light enclosure for a ship described in this embodiment is a steel hull light enclosure 1a, including welded aluminum honeycomb panels 4a and upper steel fence 5a, lower steel fence 6a, steel-aluminum composite transition joint 7a, welded joint 8a. The upper steel fence 5a is set under the upper steel deck 2a, the height is generally 200mm-300mm, the thickness is determined according to the design of the ship, and connected with the upper steel deck 2a by welding; the lower steel fence 6a is set on the lower steel deck 2a. Above the deck 3a, the height is generally 200mm-300mm, the thickness is determined according to the design of the ship, and is connected to the lower steel deck 3a by welding; the welded aluminum honeycomb panel 4a is set between the upper steel fence 5a and the lower steel fence 6a, and is connected to the upper steel fence 5a and the lower steel fence 6a respectiv...

Embodiment 2

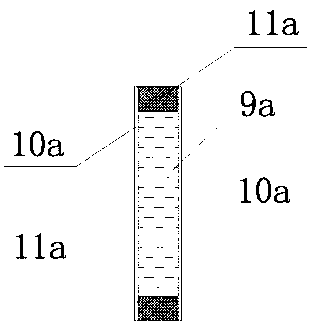

[0042] Example 2, such as Figure 5 to Figure 8 As shown, a welded aluminum honeycomb light enclosure for ships described in this embodiment is an aluminum hull light enclosure 1b, including welded aluminum honeycomb panels 4b and solder joints 8b. The welded aluminum honeycomb panel 4b The upper part is welded to the upper aluminum deck 2b, and the lower part is welded to the lower aluminum deck 3b; the adjacent welded aluminum honeycomb panels 4b The joint is welded to form a welded joint 8b.

[0043] The welded aluminum honeycomb panel 4b includes an aluminum honeycomb core set in the middle 9b and respectively brazed to the aluminum honeycomb core 9b The aluminum plates on the left and right sides 10b. The welded aluminum honeycomb panel The width of 4b is 1000mm, the thickness is 5mm-40mm, and the height is determined according to the distance between the upper aluminum deck 2b and the lower aluminum deck 3b. The aluminum honeycomb core 9b The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com