Non-screen pipe compound fracturing fabric network framework gravel-filling sand prevention method

A composite fracturing and fiber network technology, applied in the field of sand production of heavy oil wells, can solve the problems of increasing construction difficulty, reducing oil layer permeability, and high cost, achieving significant comprehensive economic benefits, not damaging oil layer permeability, improving production efficiency and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The following examples describe the present invention in more detail:

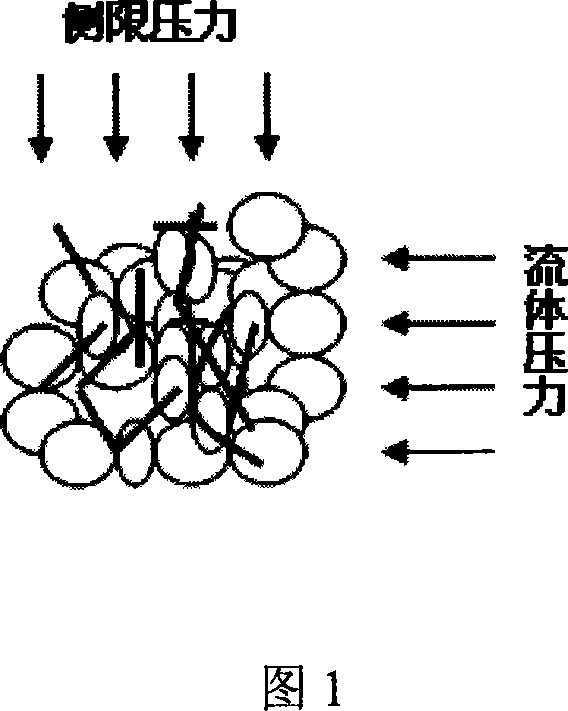

[0024] The method of the present invention includes injecting a pad fluid into the well, and the pad fluid is composed of two parts. Firstly, injecting the first pad fluid is prepared by microemulsion solution and formic acid disclosed in the patent document No. 200610009675.8 The weak aqueous solution that forms, its proportioning is that every ten tons of water adds microemulsion and 2% formic acid that account for water weight; Add 2% guar gum and 20 tons of sand to 40 tons of water to form a viscoelastic sand-carrying liquid. The fiber used as a network agent is added to the second pre-fluid in an amount of 1% of the weight of the second pre-fluid. The fiber used as a network agent is a chopped glass fiber that meets the following conditions: a high temperature resistance of 800-1000 ° C, a fiber soaked in an aqueous solution with a pH value of 9 prepared by sodium bicarbonate, and a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com