Sieve tube free composite fracturing fibre sand prevention process

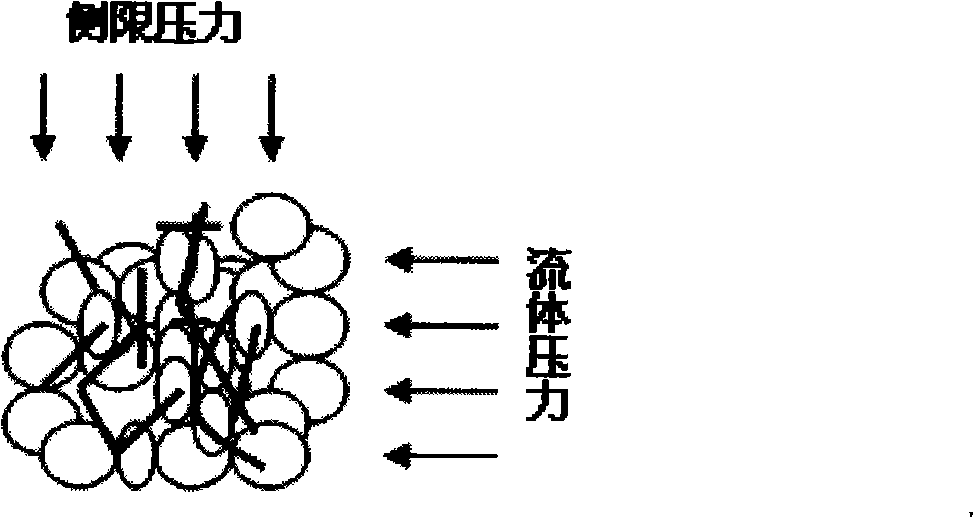

A process and fiber technology, applied in the field of new oil recovery technology, can solve the problems of unstoppable fine sand, increase construction difficulty, reduce oil layer permeability, etc., achieve a wide range of well temperature conditions, significant comprehensive economic benefits, and no The effect of impairing reservoir permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples describe the present invention in more detail:

[0023] The oil well sand control process of the present invention comprises three stages of injecting the first pre-fluid, the second pre-fluid and the filling agent. The first pre-fluid is mixed with microemulsion and hydrochloric acid; the second pre-fluid The liquid is the sand-carrying fluid used for oil well fracturing; the filling agent is a mixture of fibers and sand. Wherein: the volume ratio composition of the first pretreatment liquid is that microemulsion accounts for 1.5%~1.9%, hydrochloric acid accounts for 13.3%~22.5%, and the balance is water; Latex is made of 1.0-3 parts of LAS, 1.5-4.5 parts of AES, 7.5-22.5 parts of sec-butanol, 10-30 parts of mixed benzene and 55-165 parts of water; it is used for oil well fracturing The viscosity of the sand liquid is 800-1000mPa·s; the weight ratio of the filling agent is composed of: sand accounts for 99.2%-98.5%, fiber accounts for 0.8%-1.5%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com