Sandwich insulation external wall panel and manufacturing method thereof

An external wall panel and production method technology, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of damage to the sealing of the thermal insulation layer, difficult to guarantee quality, affecting thermal insulation performance, etc., to speed up the construction speed, consistent product specifications, reduce The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

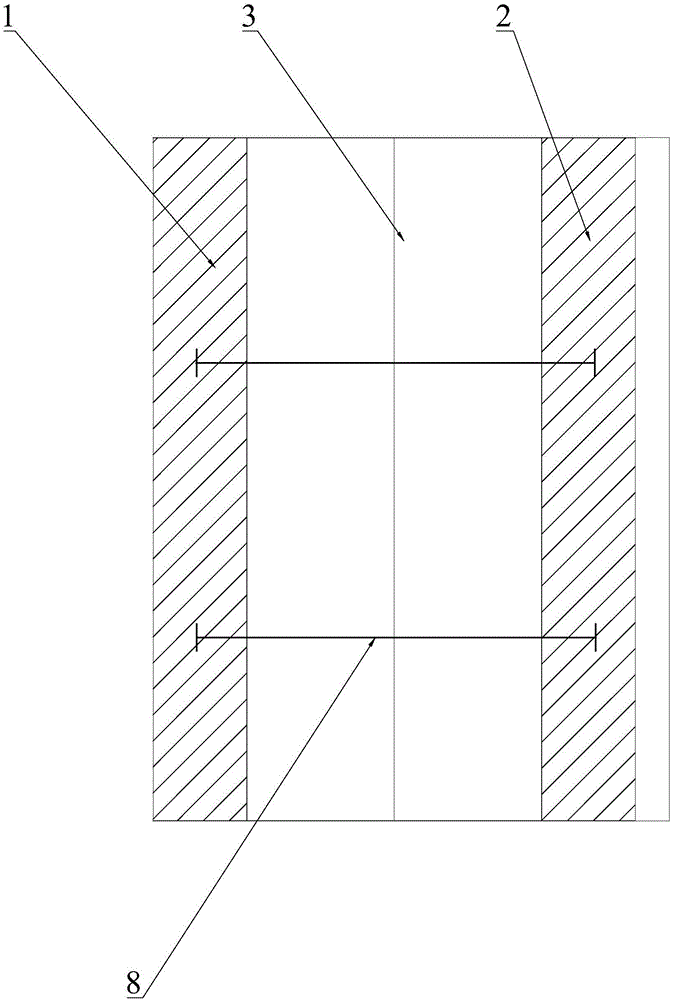

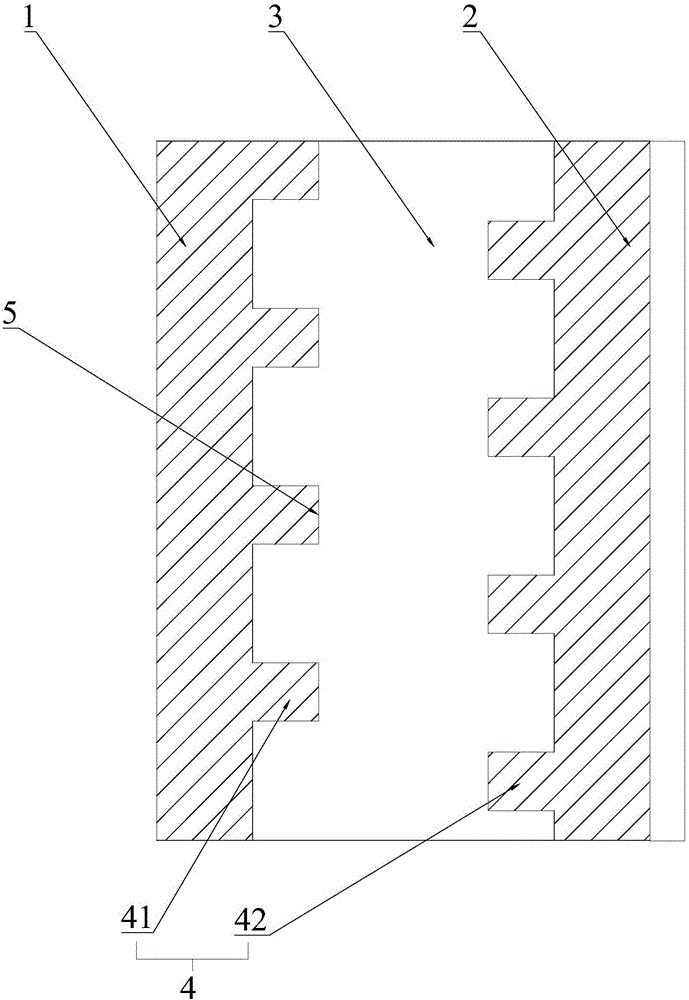

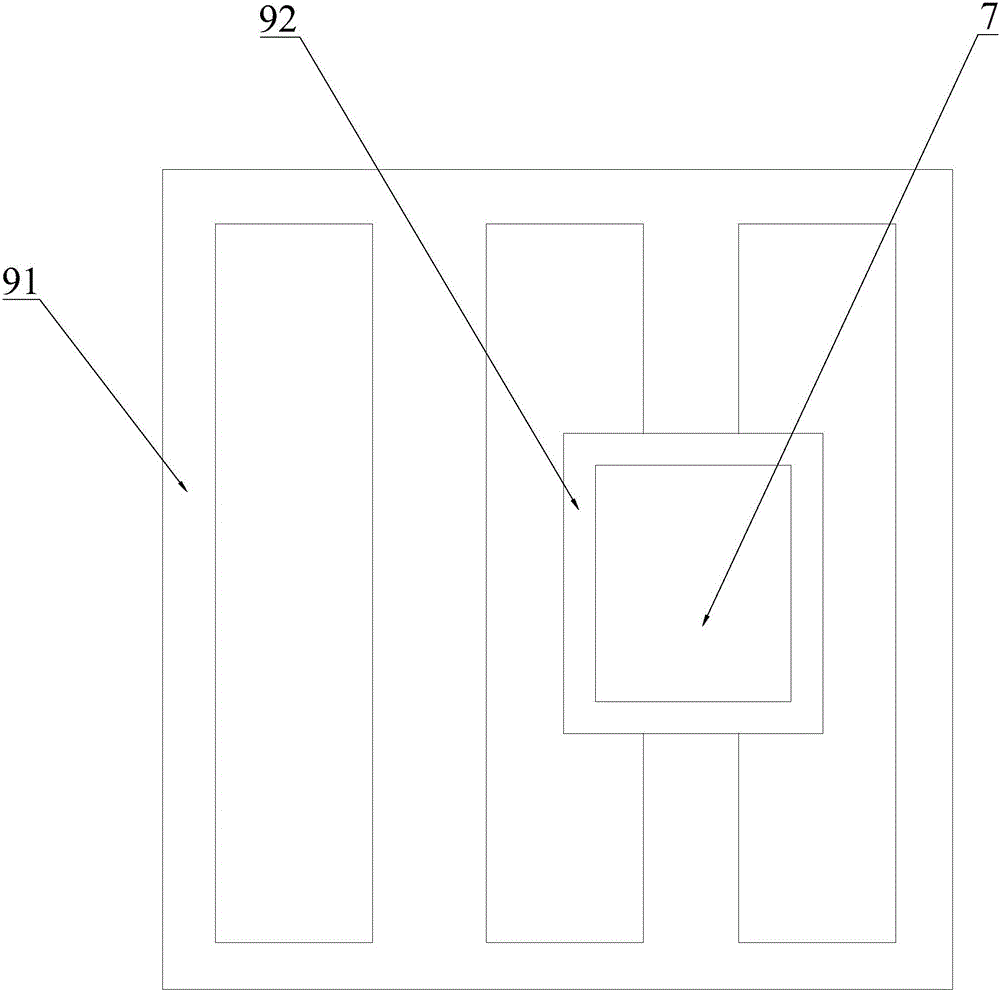

[0034] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the sandwich insulation wallboard of the present invention includes a first leaf plate 1, a second leaf plate 2 and an insulation layer 3 arranged between the first leaf plate 1 and the second leaf plate 2. The first leaf plate A blade 1, a side of the second blade 2 near the insulation layer 3 and the insulation layer 3 are respectively provided with convex ribs 4 and grooves 5 matched with the convex ribs 4, and the cross-sectional shape of the convex ribs 4 can be rectangular, triangular , semicircle, etc., that is, the convex rib 4 and the groove 5 can be matched and fitted together, and the convex rib 4 in this application is elongated, and is arranged laterally along the sandwich insulation wallboard. Since the convex rib 4 is integrated, It can greatly increase the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com