Composition for treating glass and application of composition

A composition and glass technology, applied in the direction of glass/slag layered products, synthetic resin layered products, coatings, etc., can solve the problem of low bonding strength, reduce construction technology, high compatibility, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Description of raw materials used in the examples:

[0115] A silane coupling agent:

[0116] Grade name CAS number A-1524 γ-Ureapropyltrimethoxysilane23843-64-3 A-1170 Bis-(γ-trimethoxysilylpropyl)amine82985-35-1 A-1100 3-aminopropyltriethoxysilane919-30-2

[0117] Desmodur S XP 2458: silane-terminated aliphatic prepolymer with a viscosity of about 30000-40000mPa·s at 23°C. The prepolymer contains no solvent and contains 10% Plasticizer, purchased from Covestro Polymers Co., Ltd.

[0118] Desmodur S XP 2821: a silane-terminated aliphatic prepolymer. The prepolymer contains no solvent and has a viscosity of about 20,000 mPa·s at 23° C., purchased from Covestro Polymer Co., Ltd.

[0119] Desmodur S XP 2636: silane-terminated aliphatic prepolymer. The prepolymer contains no solvent and has a viscosity of about 30000-50000 mPa·s at 23°C. It is purchased from Covestro Polymer Co., Ltd.

[0120] Desmodur S XP 2749: a silane-terminated aliphatic prepolymer. The prepolymer contains...

Embodiment 1-10

[0143] Select xylene, ethyl acetate, ethylene glycol monobutyl ether, absolute ethanol, and n-butanol to prepare organic solvents according to Table 2 below.

[0144] Table 2 Organic solvents

[0145] Solvent the amount Ethyl acetate 20% by weight Xylene 40% by weight Absolute ethanol 30% by weight Ethylene glycol monobutyl ether 5 wt% N-butanol 5 wt%

[0146] The silane-terminated polyurethane prepolymer and the above-mentioned organic solvent were mixed for 5 minutes; then an appropriate amount of silane coupling agent and 1,8-diazabicycloundec-7-ene (DBU) were added and mixed for 30 seconds. Place the mixture on a shaker and continue to shake for about 40 minutes. After the solution is evenly shaken, the compositions of Examples 1-10 are obtained. The amounts of raw materials used are shown in Table 3 below.

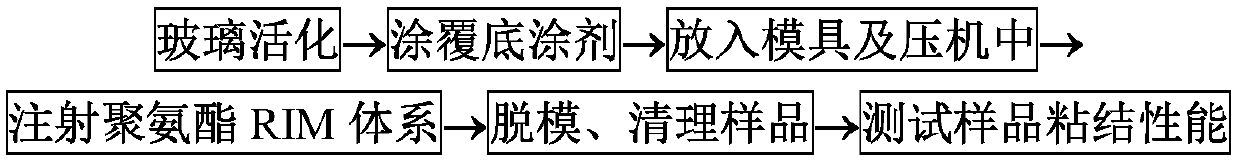

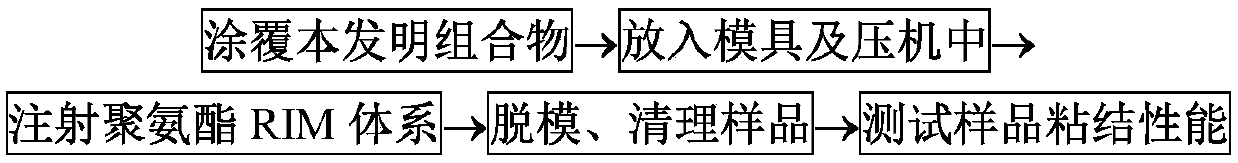

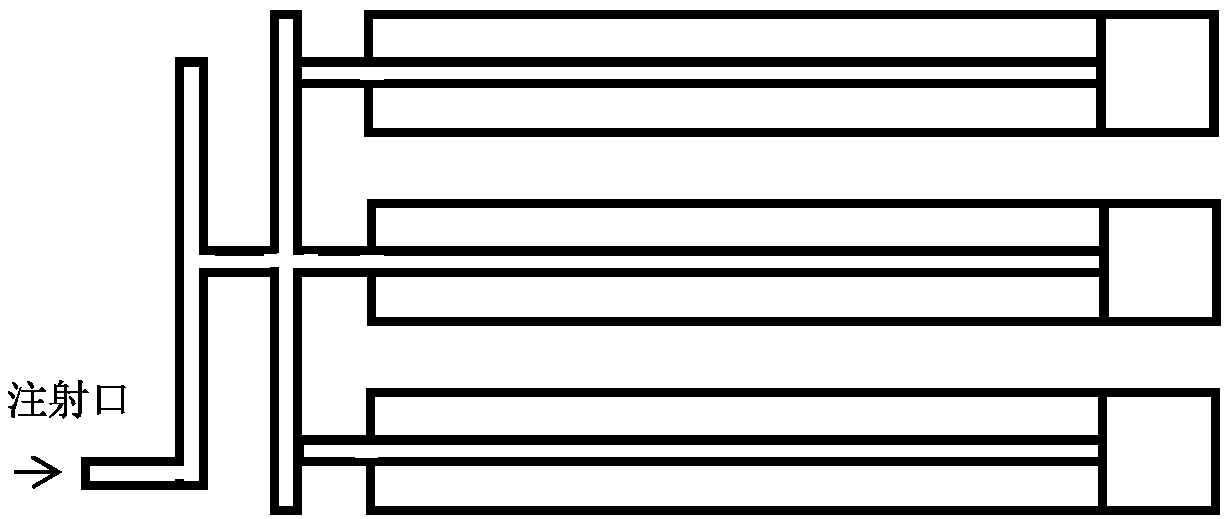

[0147] At room temperature, place the cleaned and completely dry glass test sample on the workbench. Dip a small amount of the composition of Examples 1-10 with a...

Embodiment 11-15

[0159] As described in Examples 1-10, xylene, ethyl acetate, ethylene glycol monobutyl ether, absolute ethanol, and n-butanol were selected to prepare organic solvents according to Table 2.

[0160] Mix the silane-terminated polyurethane prepolymer and the above-mentioned organic solvent for 5 minutes; then add an appropriate amount of silane coupling agent and DBU and continue to mix for 30 seconds; place the mixture on a shaker and continue to shake for about 40 minutes, and the solution is evenly shaken to obtain the example The composition of 11-15, the amount of raw materials used is shown in Table 4 below.

[0161] At room temperature, place the cleaned and completely dry glass test sample on the workbench. Dip a small amount of the composition of Examples 11-15 with a brush and apply it to the glass plate, making the brush as thin as possible. Use a wiper to control the glass surface-wet film thickness to 50um. The surface dry time was measured, and the results are summari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com