Welding construction method of mechanical composite pipes for petroleum and natural gas transportation

An oil and natural gas and construction method technology, which is applied in the field of welding construction of mechanical composite pipes for oil and natural gas transportation, can solve the problems of dilution of lining corrosion-resistant alloy, hidden danger of welding seam quality, complicated welding bead design, etc. The effect of simplifying operation and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

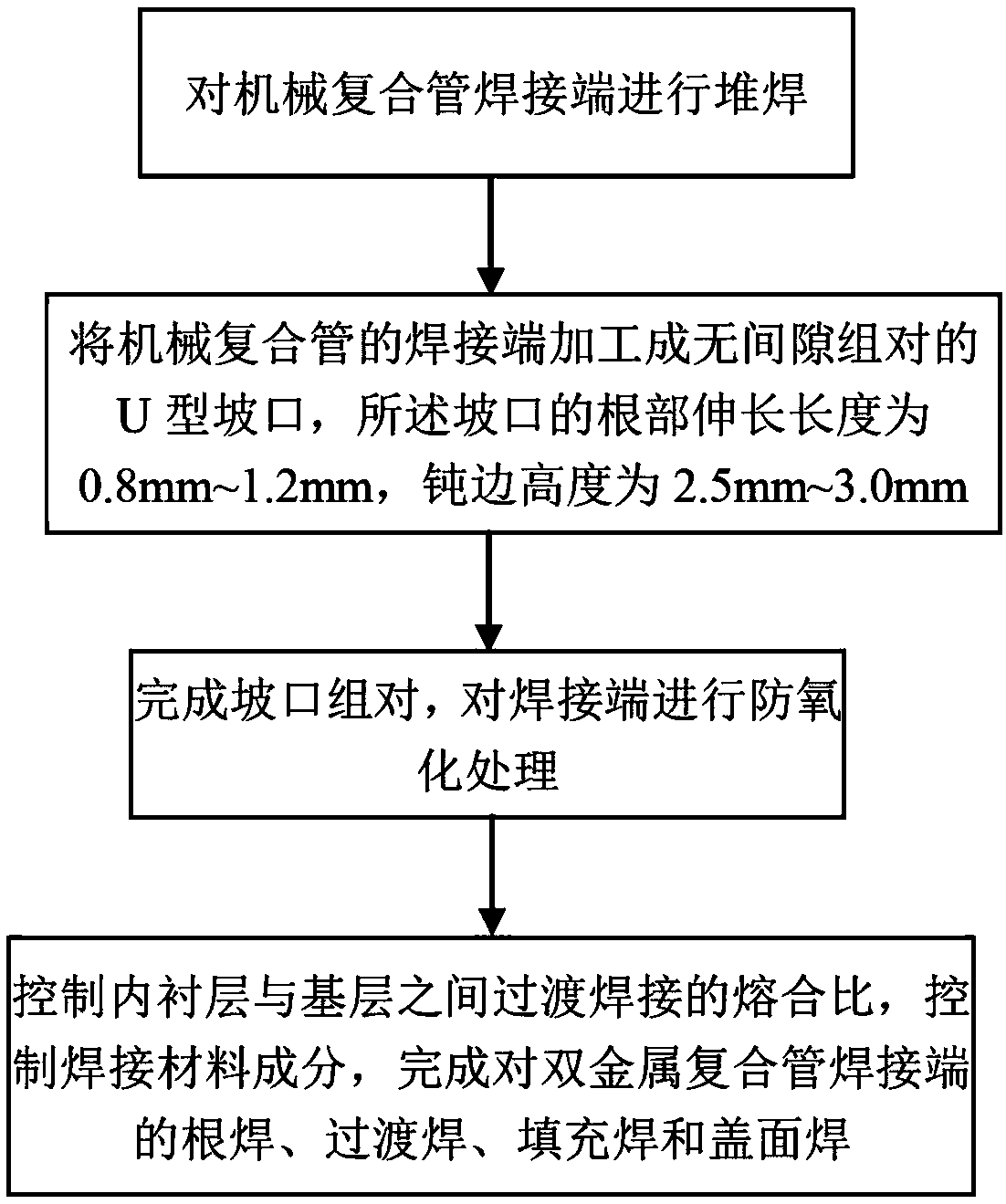

[0022] Hereinafter, a welding construction method of a mechanical composite pipe for oil and gas transportation according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

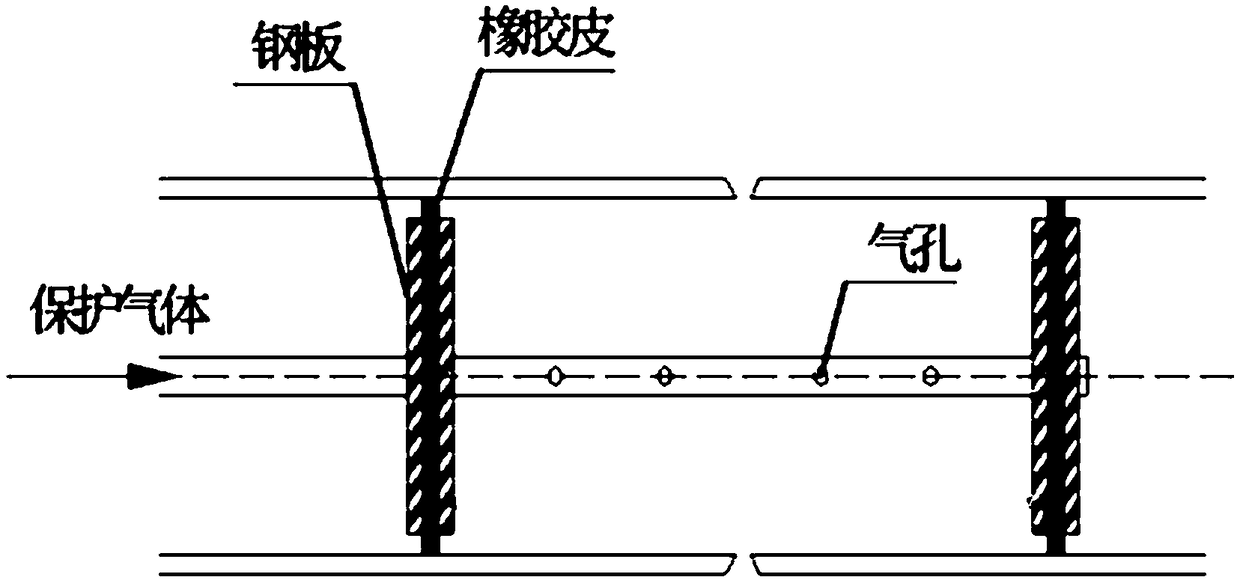

[0023] Specifically, for the welding of mechanical composite pipes for oil and gas that transport acidic corrosive media such as chlorine-containing particles and hydrogen sulfide, it is necessary to ensure the welding quality and improve the welding efficiency. The welding construction method of the present invention first performs surfacing welding on the pipe ends, then designs matching grooves for the welding of the mechanical composite pipe, and finally controls the root welding, transition welding, filling welding and cover welding, which can be easily Better shorten the welding process, ensure the welding quality and improve the welding efficiency.

[0024] figure 1 A schematic process flow diagram showing a welding construct...

PUM

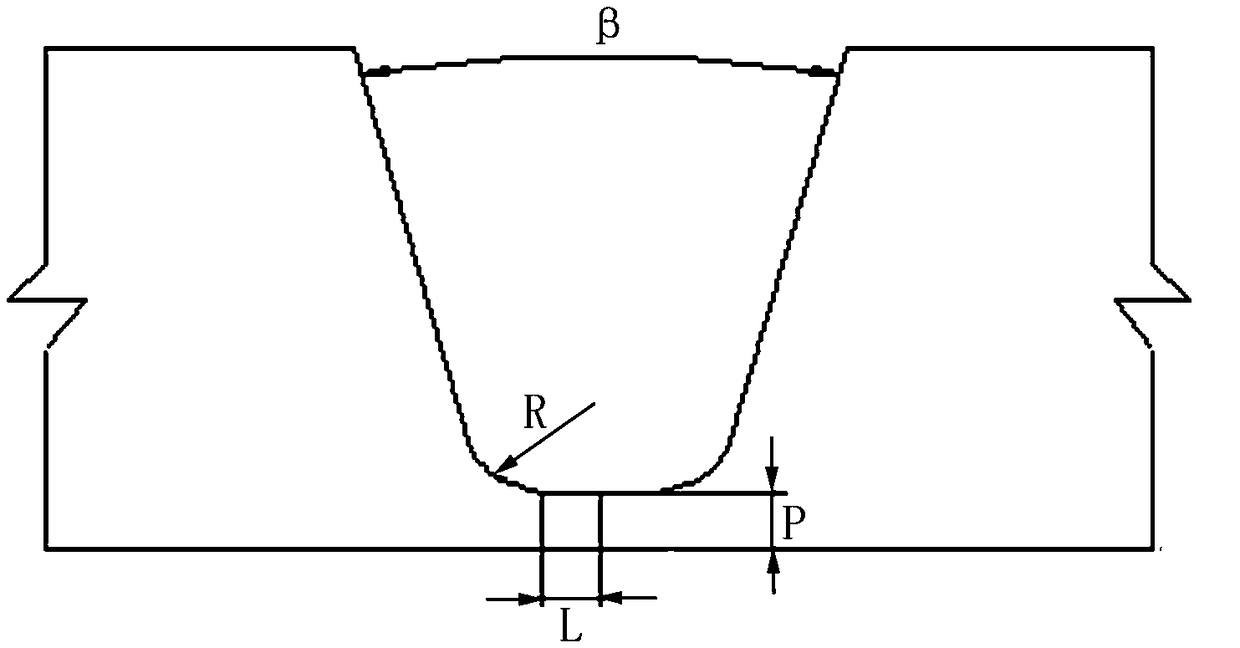

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com