A kind of scr system and its catalytic muffler and welding method of catalytic muffler

A catalytic muffler, SCR system technology, applied in the direction of muffler, machine/engine, engine components, etc., can solve the problems of large deformation, cracks, and low fatigue life of the front end cover 8', so as to improve the fatigue life and improve the fatigue life of the front end cover. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

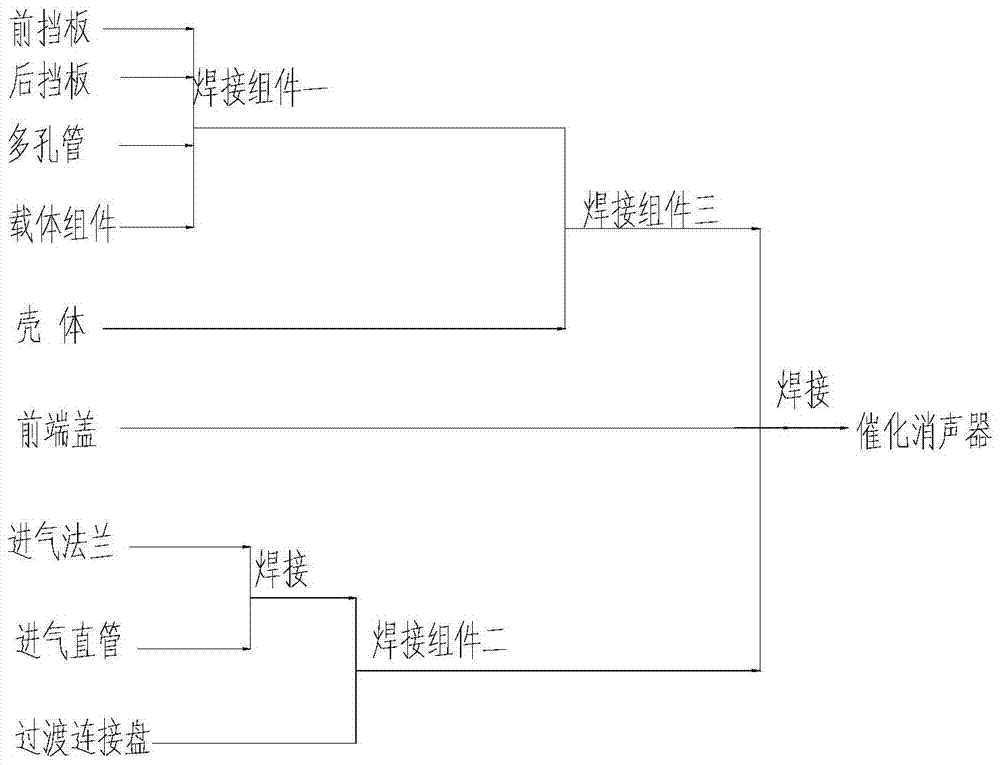

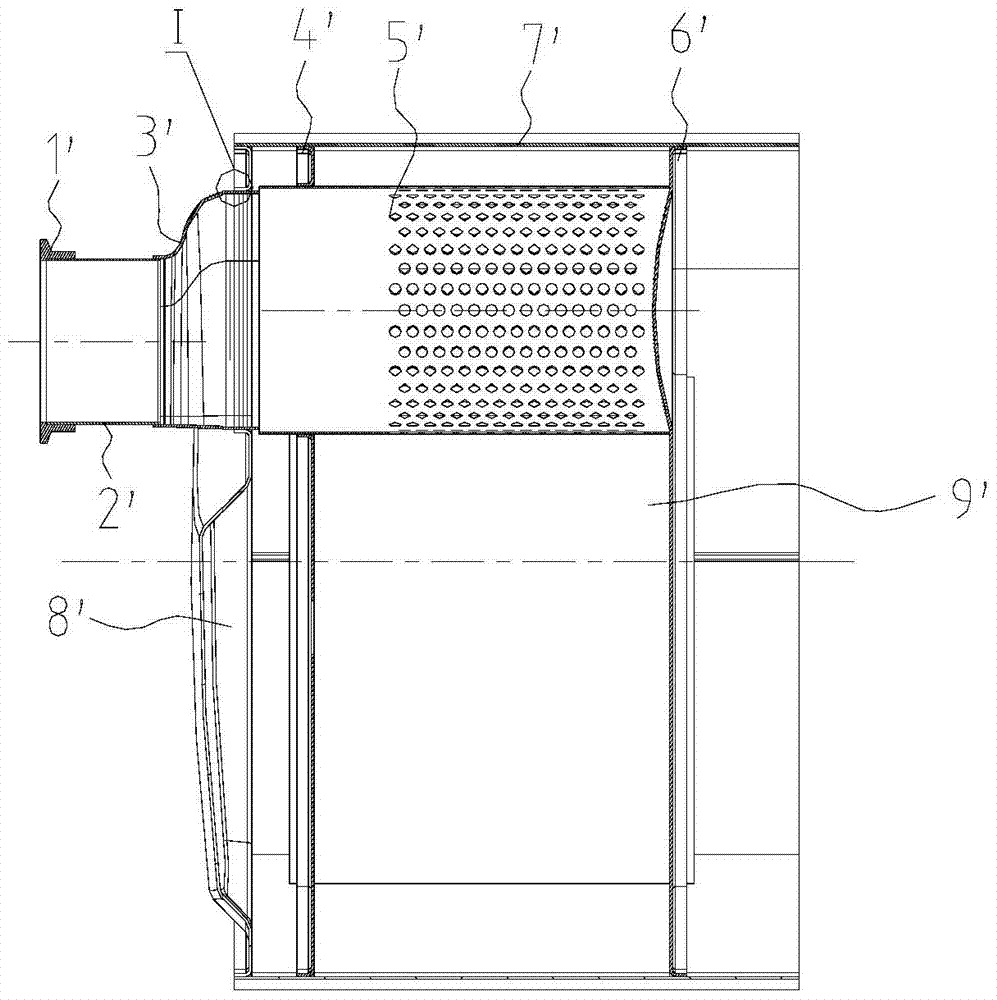

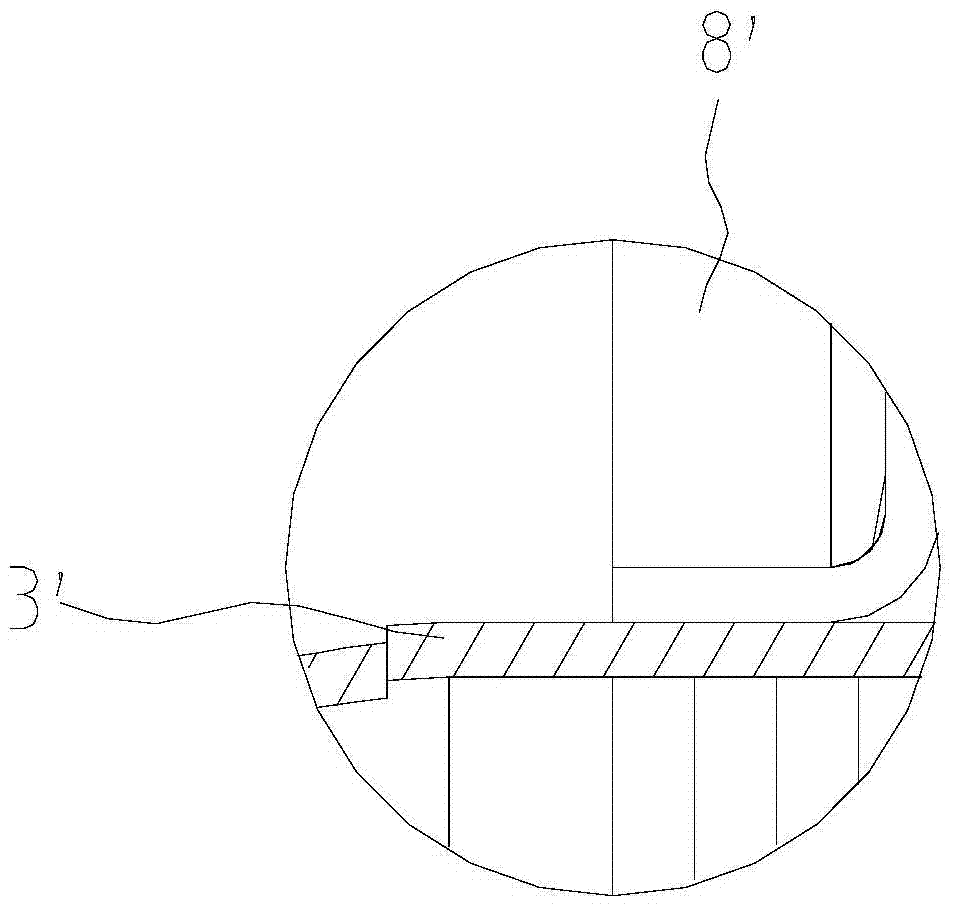

[0043] The first core of the present invention is to provide a catalytic muffler. The catalytic muffler changes the welding process during assembly, and welds the porous tube to the front end cover and / or the transition connection plate, so that the transition connection plate is supported by a single point of the front end cover. point support, thereby greatly improving the fatigue life of the catalytic muffler. The second core of the present invention is to provide an SCR system including the catalytic muffler. The third core of the present invention is to provide a welding method for the catalytic muffler.

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] It should be noted that the orientation words such as "front end" and "rear end" appearing in this artic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com