High energy-saving heat preservation aluminum-plastic combined window

An aluminum-plastic and aluminum alloy technology, applied in windows/doors, door/window applications, door/window protection devices, etc., can solve problems such as too many processing steps, increased material costs, cracking of window frame welding angles, etc., to achieve optimization The cost of the whole window, the effect of improving the thermal insulation effect, and the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0017] The "upper and lower" parts described below take the picture as the object of expression, the upper part is the upper part shown in the picture, and the lower part is the lower part shown in the picture, which are only used for description.

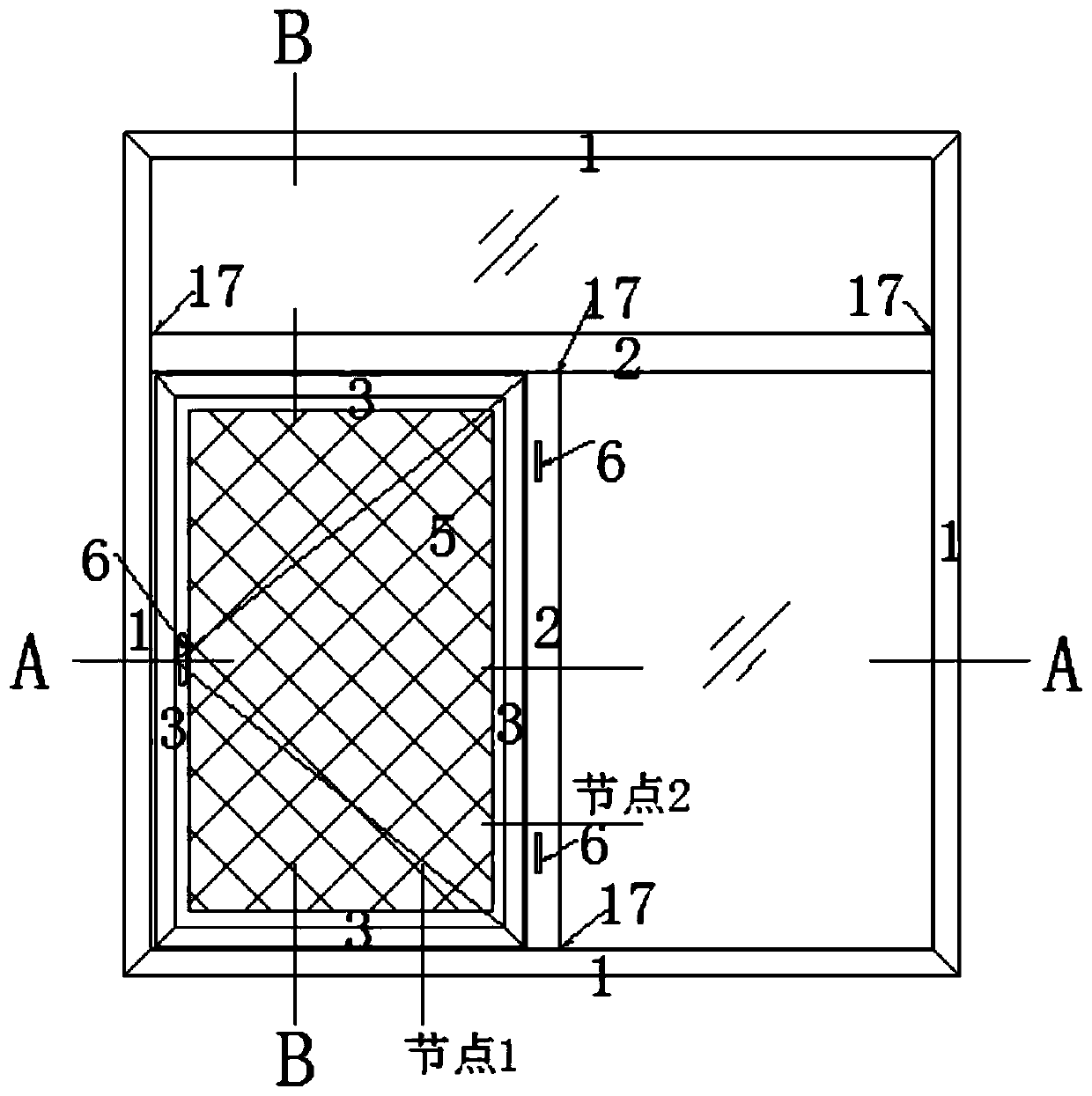

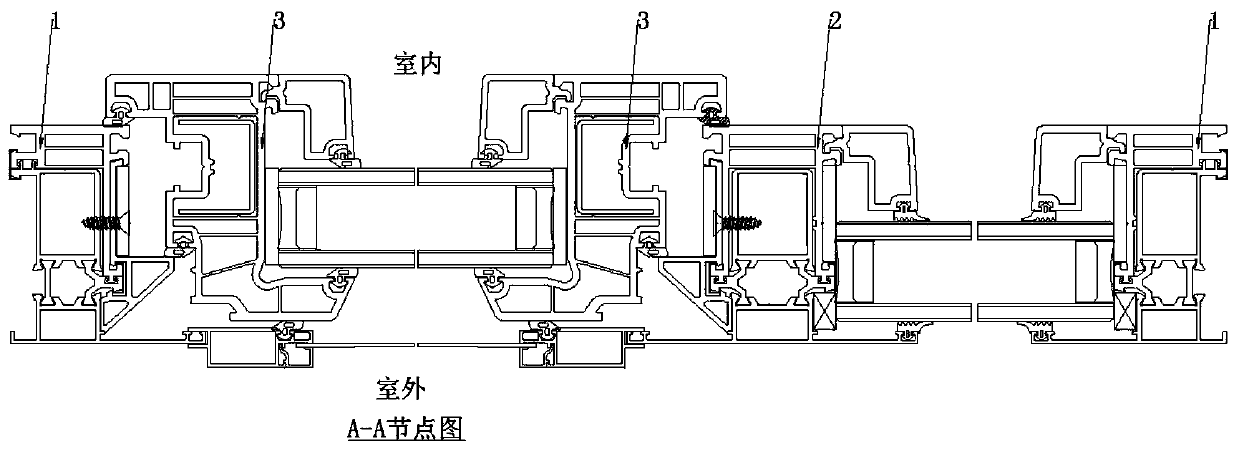

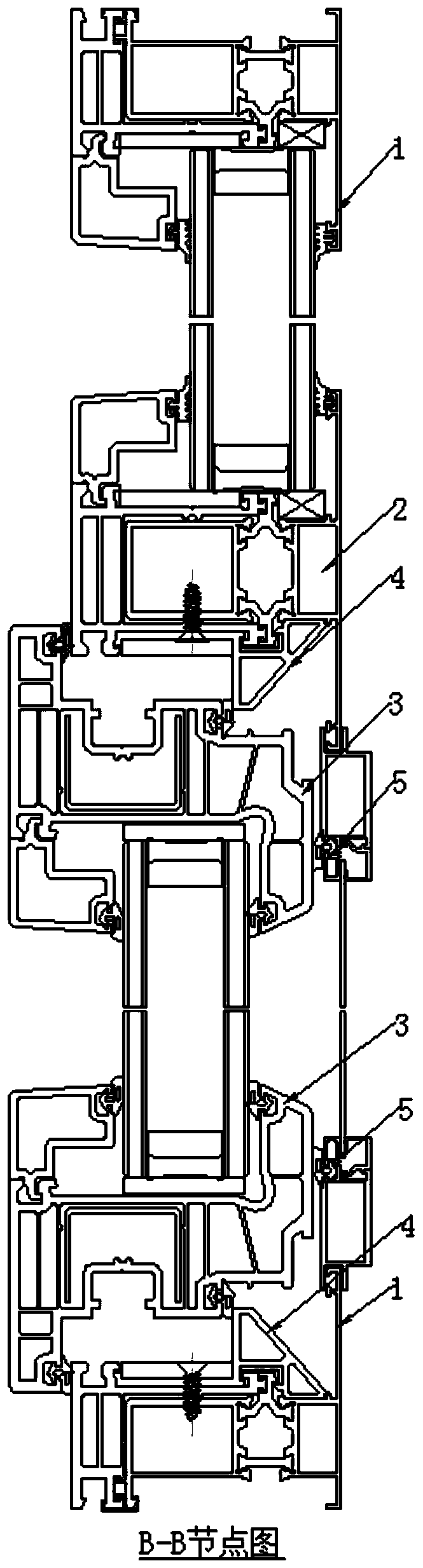

[0018] A high-energy-saving thermal insulation aluminum-plastic combined window, including a window frame 1, a stile 2, an opening fan 3, and a gauze 5. Profiles 8 and 15 are made into a multi-cavity structure, and after assembly with the opening fan 3 of plastic profiles, the whole window can achieve the high energy-saving performance of plastic profile windows, and the high-strength corrosion resistance of aluminum alloy windows with broken bridges, and at the same time, the sales unit price is low Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com