Micro-deformation welding method of middle groove of scraper conveyor

A scraper conveyor and micro-deformation technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of fast cooling speed, low efficiency, and large welding restraint stress, so as to reduce the consumption of welding materials and improve the welding quality. Stable and control the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018]

[0019]

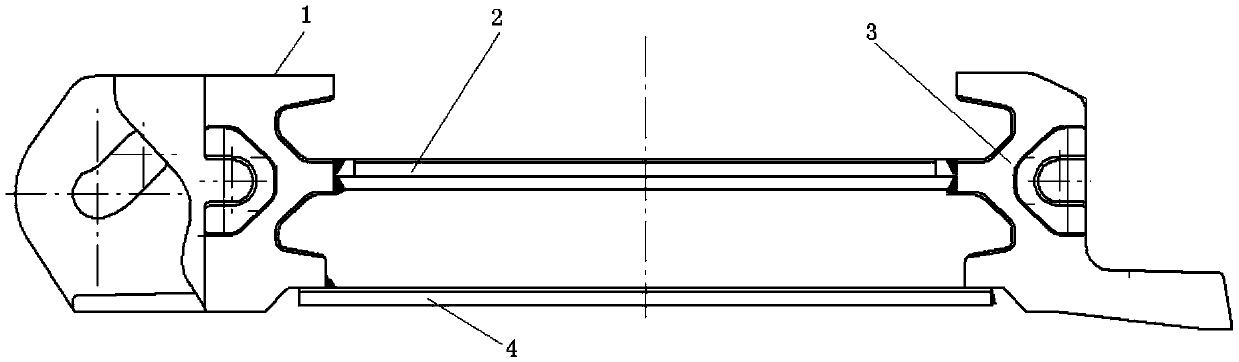

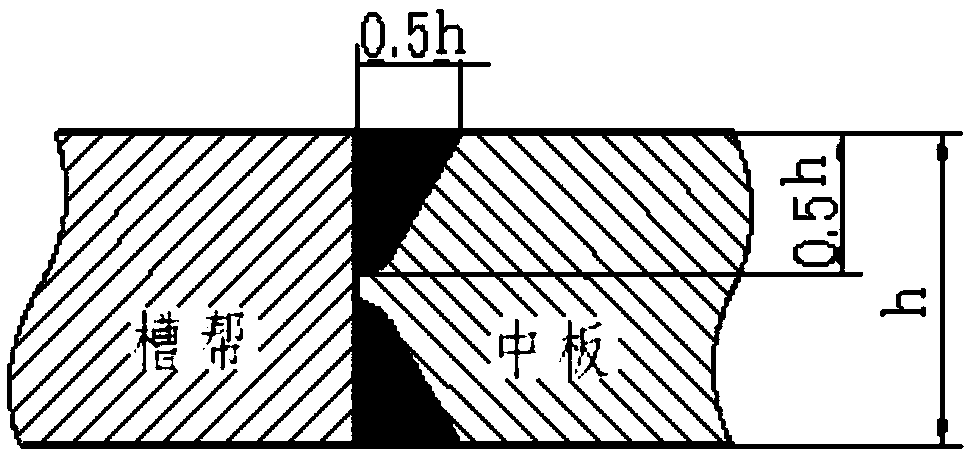

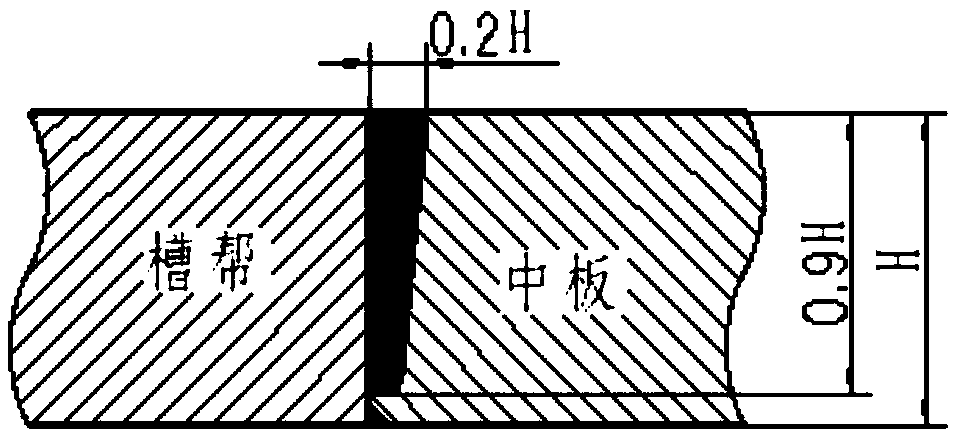

[0020] Firstly, rotate the blade groove side 3 and the baffle groove side 1 by 180 degrees and then reverse them, and assemble the middle plate 2 on the blade groove side 3 and the baffle groove side 1 first, (after installing the middle plate 2, you can install it first , that is, the shovel groove side 3 and the baffle groove side 1 middle plate 2 are fixed together by welding according to the size requirements of the drawing. Of course, this point installation step can also be omitted.) Use narrow gap MAG welding to complete the back weld of the middle plate 2 welding, and then assemble the bottom cover plate 4 to form a box-shaped structure, and then turn the entire box-shaped structure 180 degrees to restore the positive placement of the blade groove side 3 and the baffle plate groove side 1 (that is, figure 1 The position of the middle groove shown in the figure), and then use narrow-gap MAG welding to weld the front weld seam of the middle plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com