Ultra-short closure section of rotation construction bridge and construction method thereof

A closing section and swivel technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the impact on the operation of existing buildings, the difficulty of ensuring safety, and the complicated construction process of the post-casting closing section, etc., to achieve Easy to adjust deviation correction, reduce construction risk, and solve the effect of overturning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

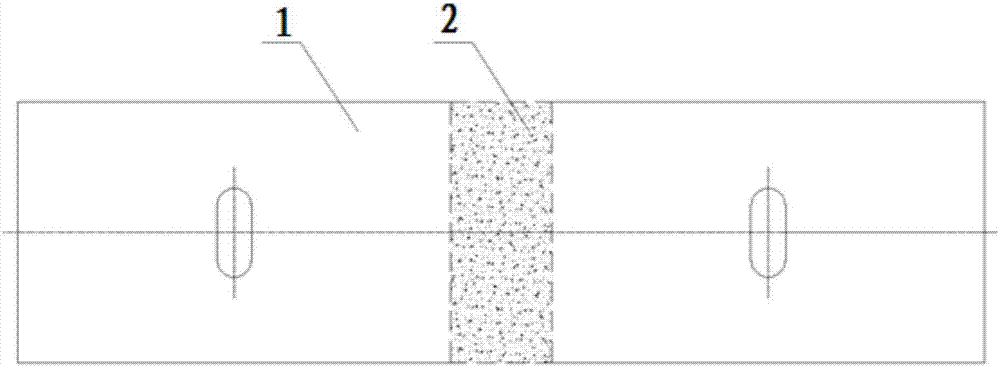

[0027] like figure 1 As shown, there is a large post-cast closing gap between the two sections of the swivel beam body 1 of the traditional swivel construction bridge, resulting in a large width of the closing section 2, and the construction process of the post-casting closing section is complicated.

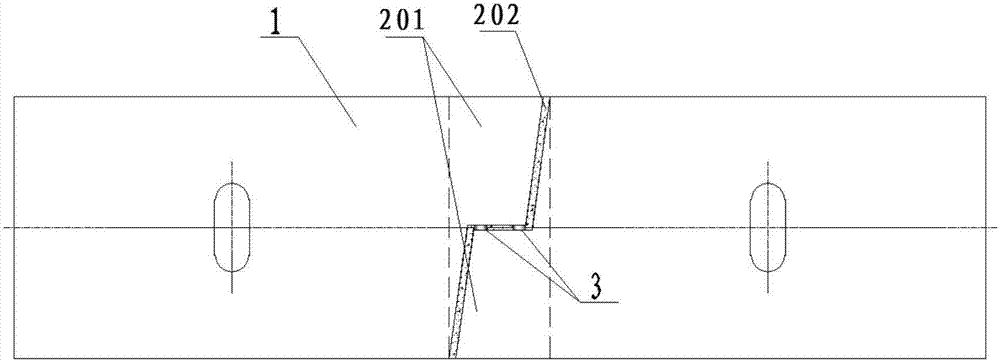

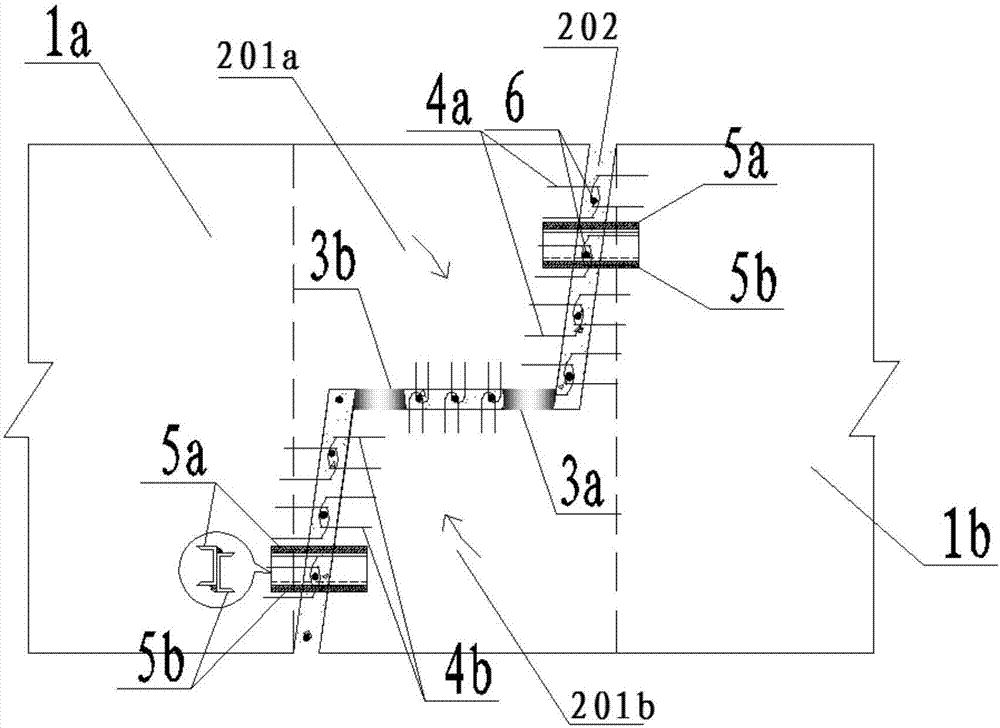

[0028] like figure 2 and 3 As shown, the closing section of the present invention is composed of a pouring closing section 201 and a post-casting closing section 202. In order to prevent the two sections of swivel beams from interfering with each other during the rotation process, the first pouring closing section 201 is divided into two sections along the longitudinal axis of the bridge. Left half 201a and right half 201b. The two sections of swivel beams 1 are respectively a first swivel beam 1a and a second swivel beam 1b, the end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com