Construction method of waterproof heat preservation roof

A construction method and roof panel technology, applied in the direction of roof covering layer, building roof, etc., can solve problems such as steel plate leakage, and achieve the effect of reducing roof load, reducing roof structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

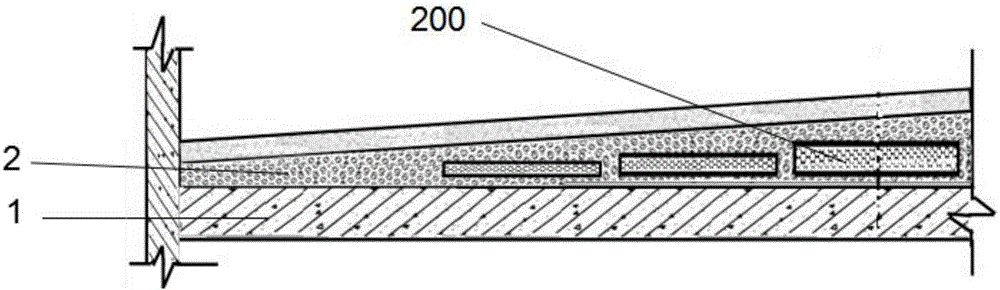

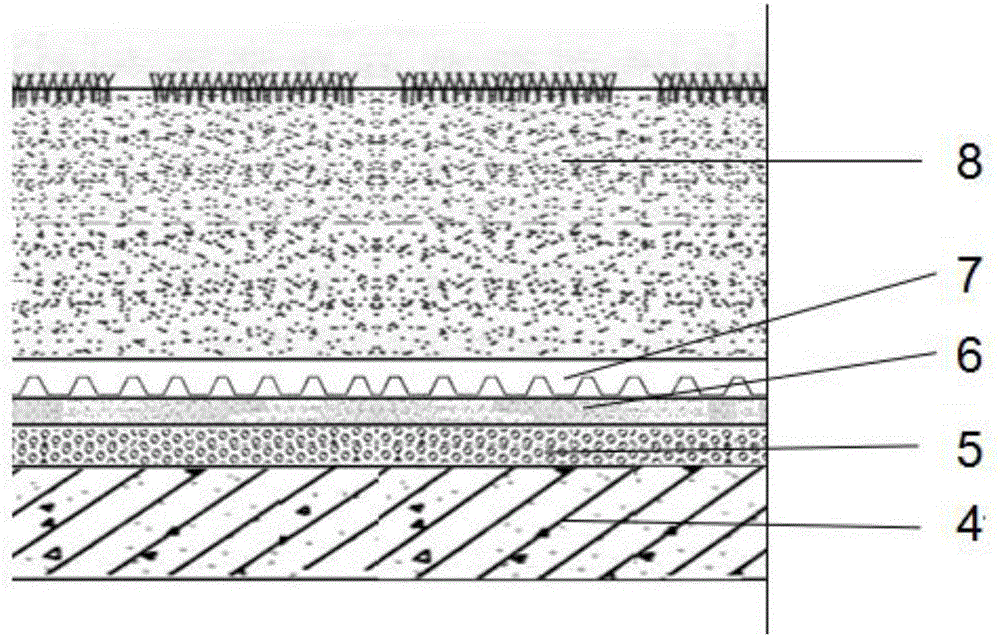

[0033] The invention discloses a construction method for a waterproof and heat-preserving roof. figure 1 As shown, the method includes at least the following steps:

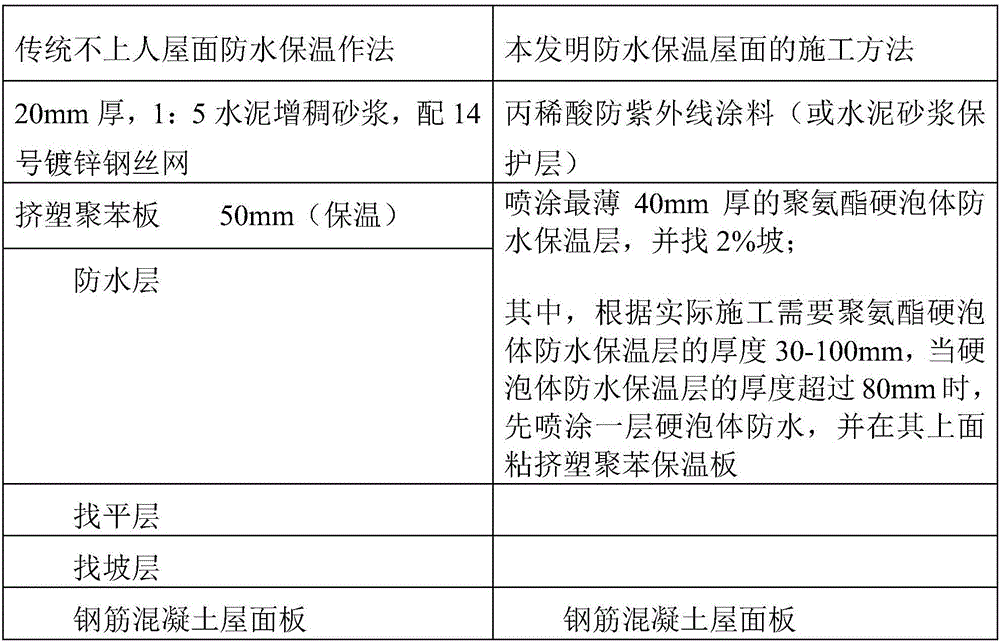

[0034] Spray polyurethane rigid foam waterproof insulation layer 2 on the roof panel 1.

[0035] The construction process of the thermal insulation and waterproof roof in the prior art is as follows: lay extruded polystyrene board with a thickness of 80 mm on the roof panel; then lay a waterproof layer; lay DS mortar with a thickness of 20 mm as a leveling layer; Concrete is used as the slope layer with a slope value of 2%; finally, C20 fine stone concrete is used as the roof surface layer.

[0036] In the present invention, directly spray polyurethane rigid foam waterproof insulation layer 2 on the roof panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com