Outer making up and inner casting non-bearing wall and constructing method

A construction method, a non-load-bearing technology, applied to walls, building components, buildings, etc., can solve the problems of no substantial breakthroughs in practical effects, and achieve the effects of saving engineering costs, easy construction quality, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

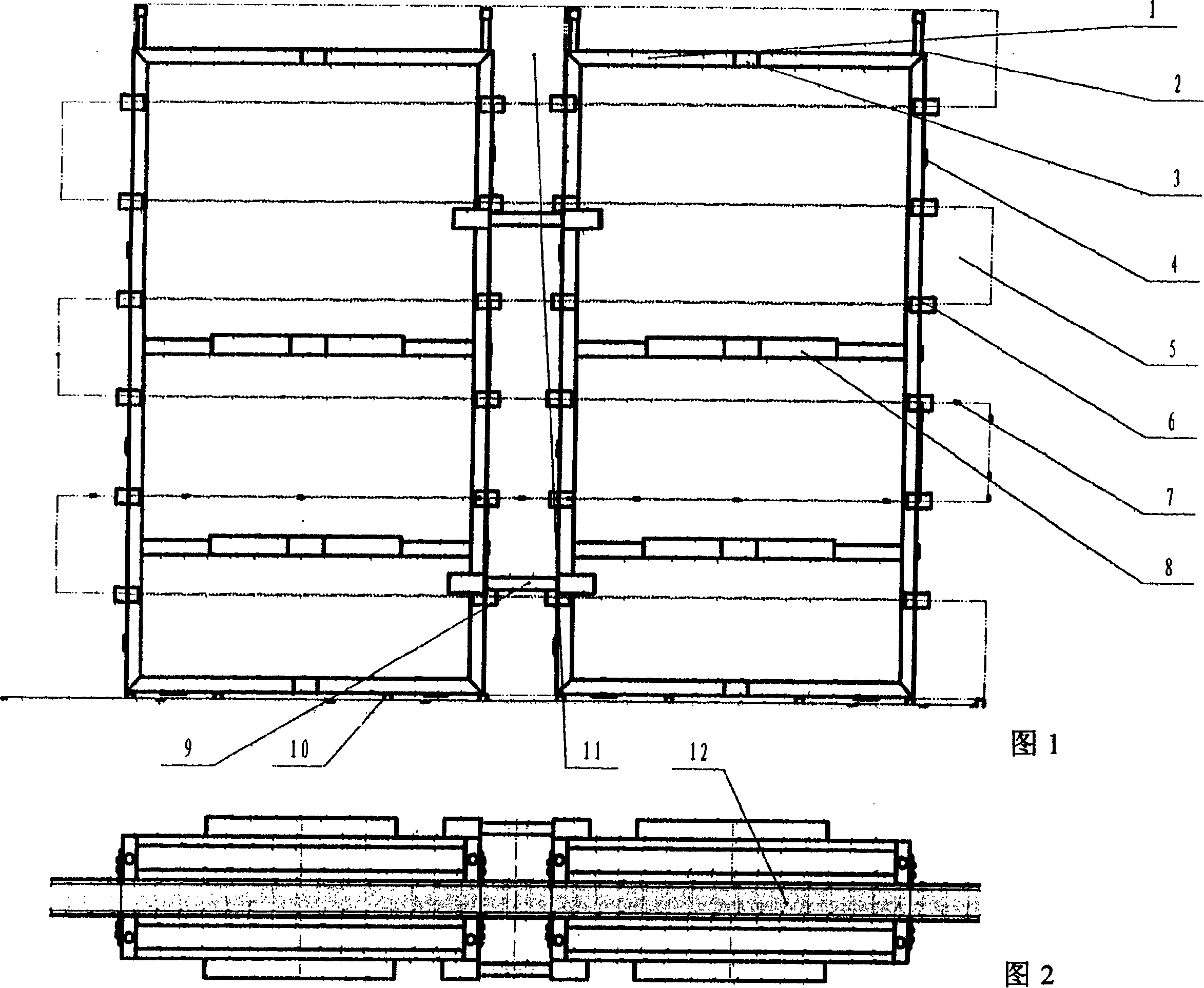

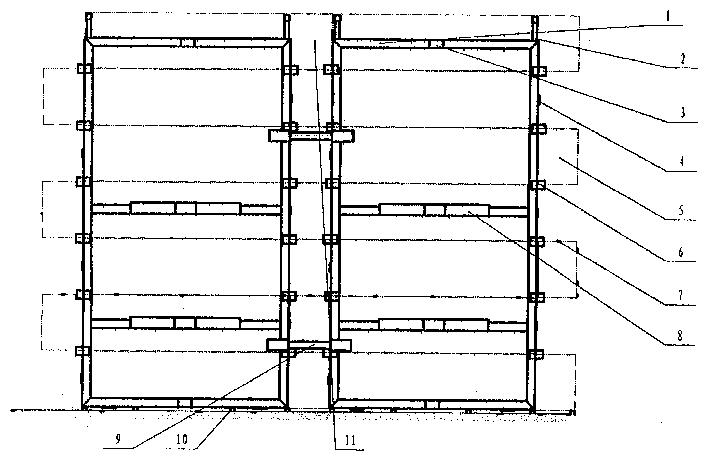

[0020] As shown in FIG. 1 , the externally assembled and internally poured non-load-bearing wall structure of the present invention is composed of an assembled shell 13 and an internally poured composite foaming material 12 . The construction steps are to adjust the height adjuster 2, width adjuster 3, and frame body clutch 4 on the assembly frame 1 to complete the length, width, and height requirements of the wall; place two strip wall panels 5 symmetrically horizontally and vertically Put it on the assembly frame and clamp it through the strip clamp 6; use an air nailer to nail the tension plate 7 and the strip wall panel 5, and then rotate the strip clamp 6 180 degrees to the outside of the assembly frame 1; Assemble strip wall panels 5 in turn until the assembly rack 1 is full. Use a manual lifting manpower forklift to transport the assembled assembly frame 1 through the forklift connector 8 to the wall masonry marking line and close up with the previously assembled assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com