Large-cantilever bent cap tensioning anchorage temporary support device and construction method thereof

A supporting device and temporary technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as large cost expenditures, and achieve the effect of less construction process, less materials and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

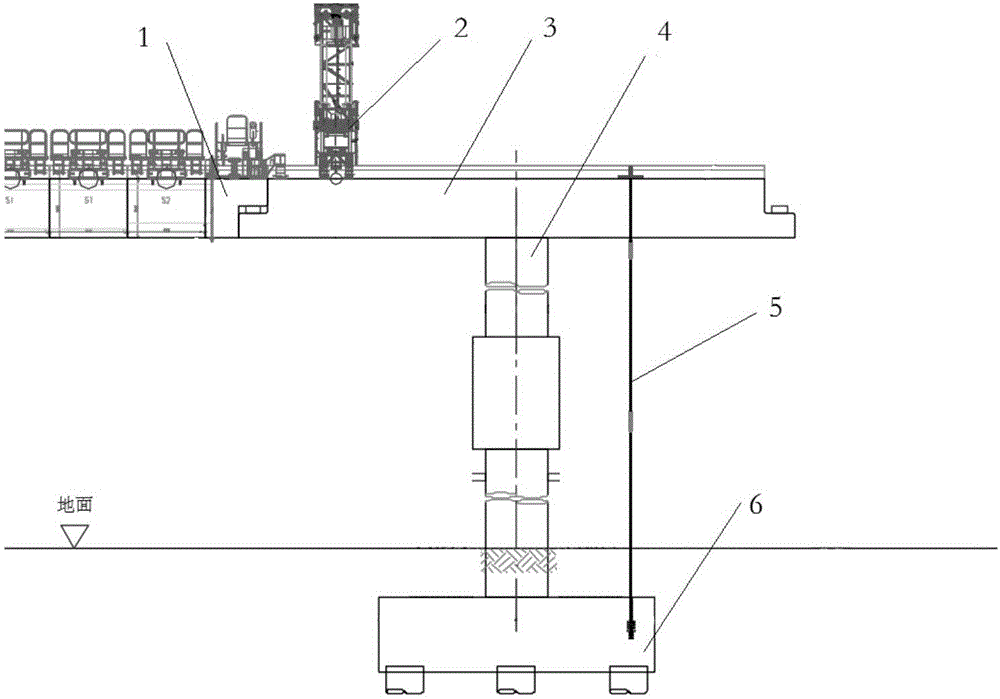

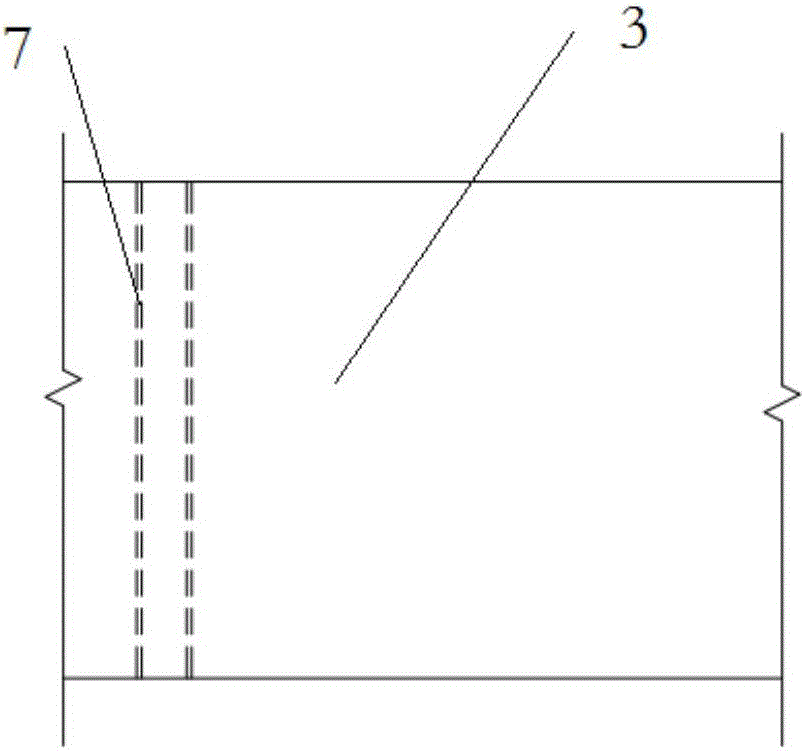

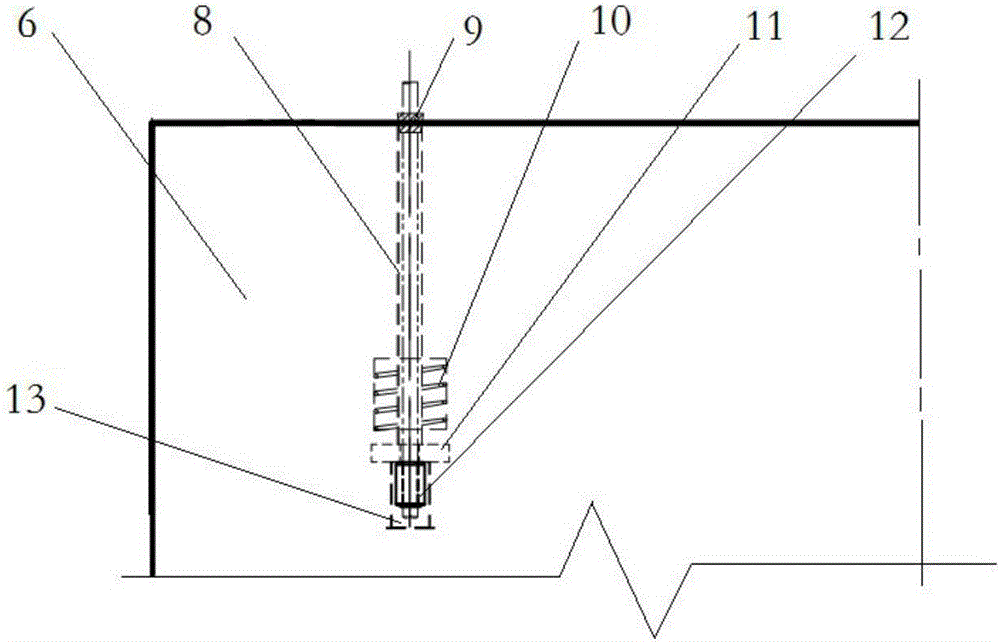

[0022] figure 1 In order to use the large cantilever cover beam of the present invention to temporarily tension the anchor support device 5 to the layout schematic diagram of the temporary support of the box girder erection of the large span cover beam 3, it can be seen from the figure that the temporary tension of the large cantilever cover beam The setting of the anchor support device 5 is not completely symmetrical to the position of the main leg 2 of the bridge erecting machine. The purpose of such setting is to adapt to the position of the lower cap 6 while taking into account the main leg 2 of the bridge erecting machine and the erected beams. 1 The load applied to the long-span cover beam 3. The installation position of the temporary tension anchor support device 5 of the large cantilever cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com