Cement-maize straw building block

A technology of corn stalks and cement, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of large energy consumption and high cost, and achieve the effect of reducing cost, simple production equipment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

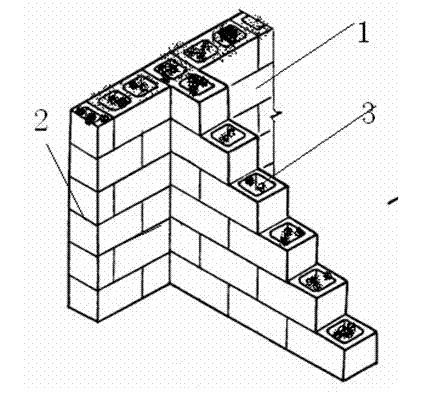

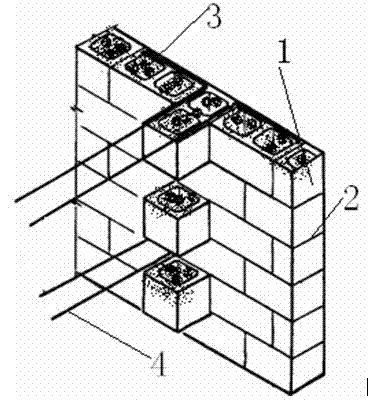

[0014] The foundation construction is the same as that of ordinary houses with ordinary clay solid brick wall structure; then the basic reinforced concrete ring beam construction is carried out, and corn straw blocks 1 are built on the ring beam, and ordinary mortar or polystyrene particle insulation block joint mortar 2 is used The wall can be left with straight stubble or slanted stubble, and when the straight stubble is left, it is necessary to add tie bars 4; a reinforced concrete ring beam is set on the upper roof, and its width is 10cm less than the thickness of the wall. Thereby avoiding ring girder cold bridges. The exterior wall is finished with polypropylene fiber cement mortar, and the interior wall is finished with polypropylene fiber mixed mortar. After the plastering is completed, the construction of decoration works such as paint is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com