Split-cabin lining pressure-relief support structure with multiple fillers, and construction method

A support structure and filling technology, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of increasing the risk of tunnel wall damage, high steel bar price, loss and danger, etc., and achieve the suppression of the displacement of the air surface , save the construction period and reduce the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

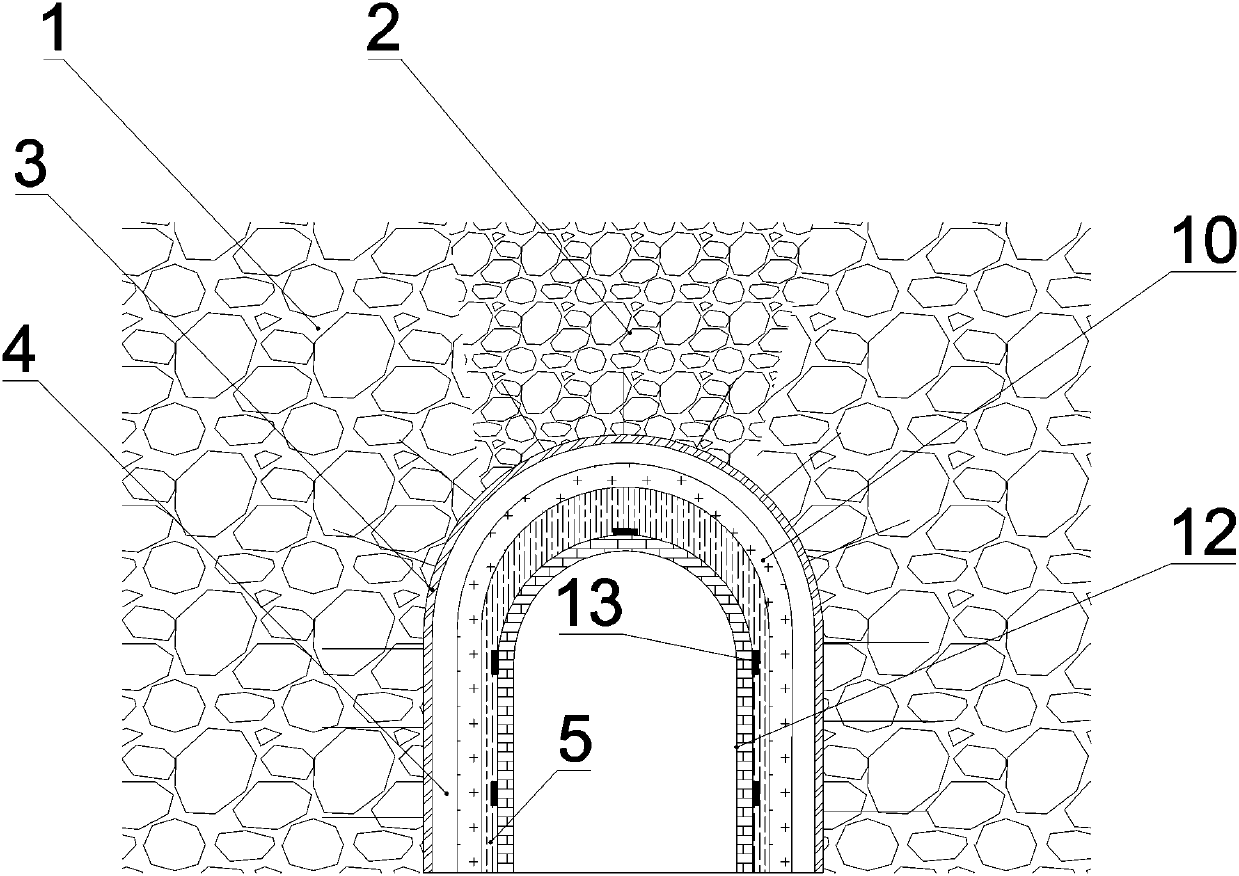

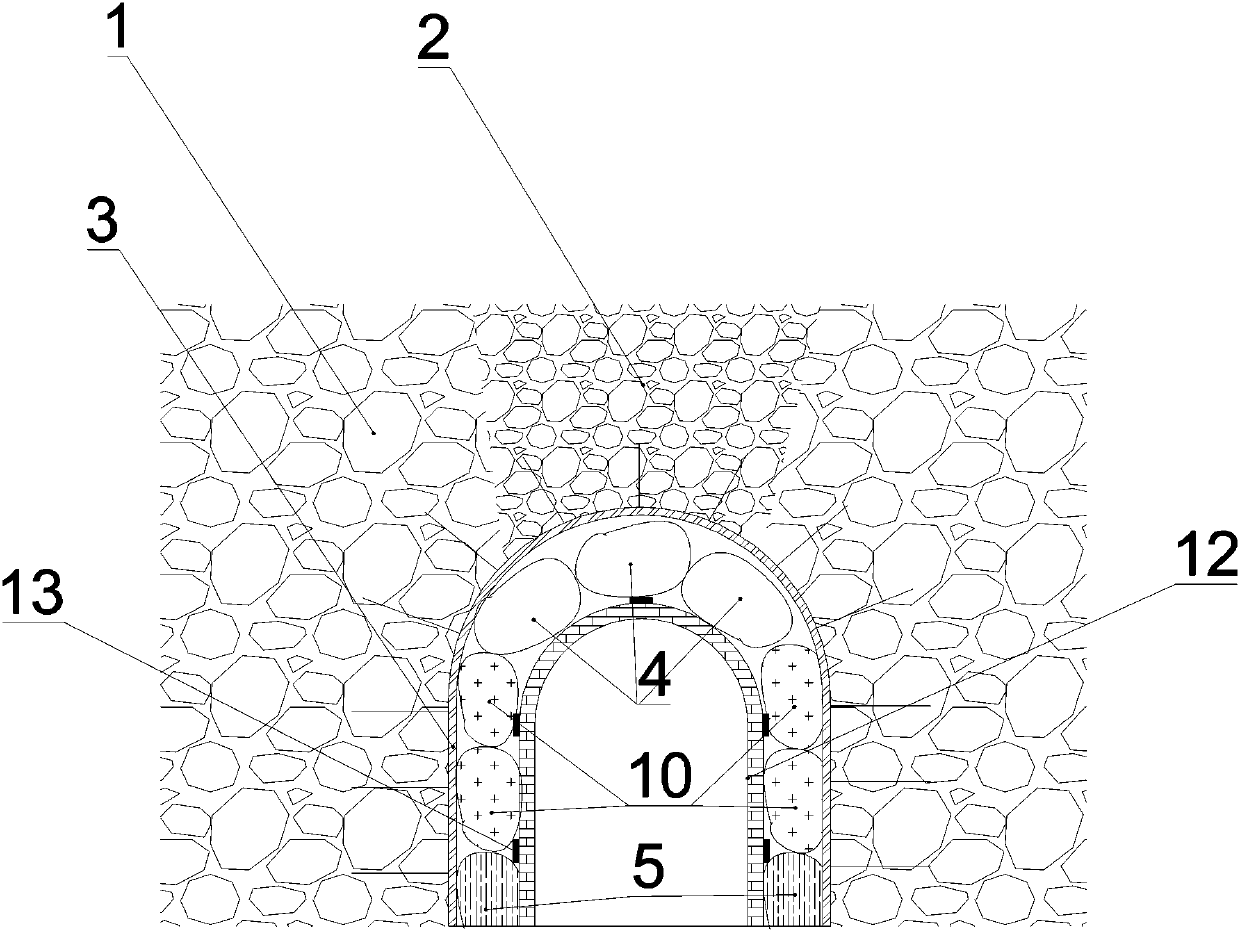

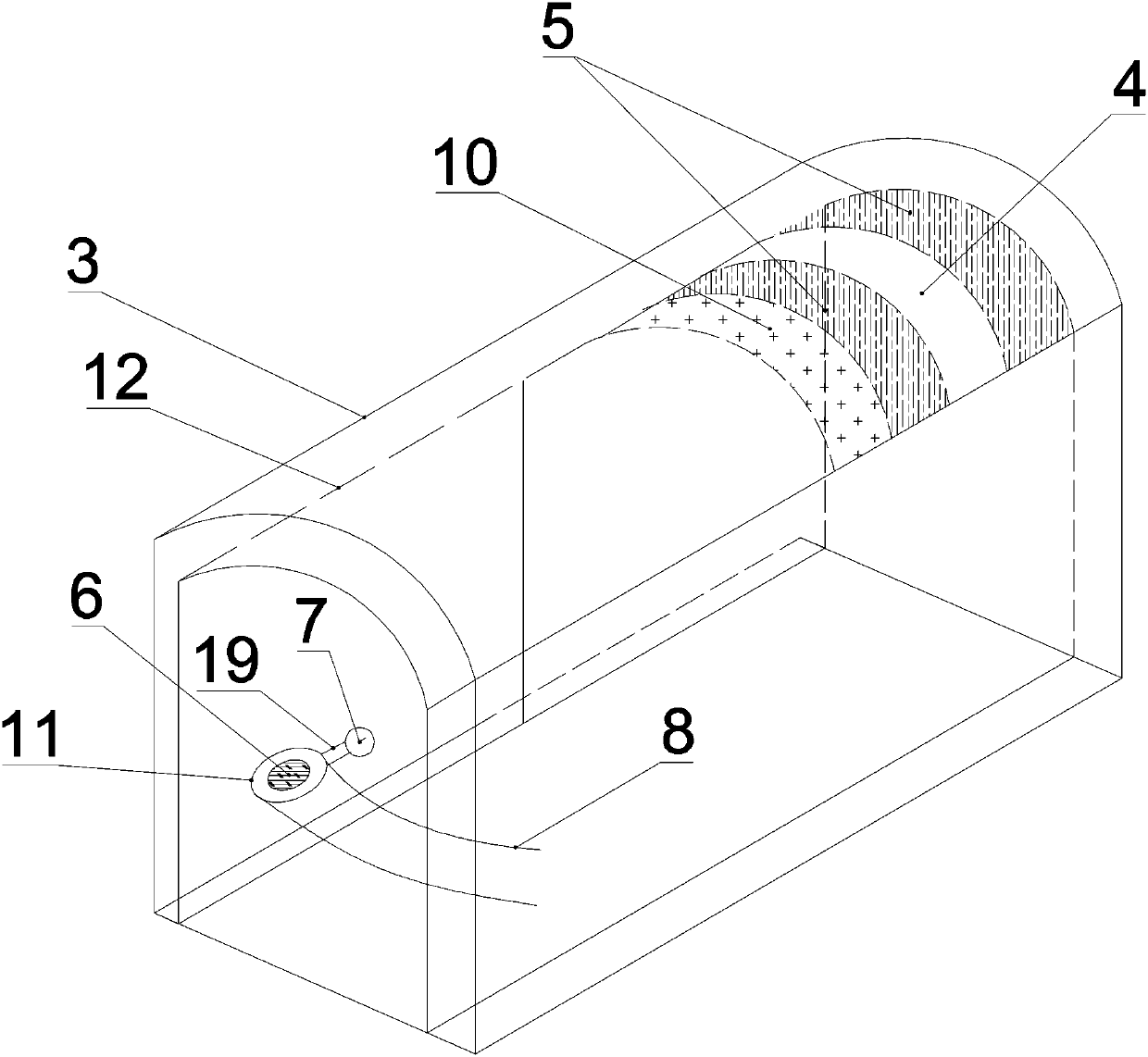

[0037] see Figure 1-6 , a kind of sub-compartment lining pressure relief support structure with multiple fillings, which includes complete surrounding rocks 1, and surrounding rock plastic zones 2 are mixed between the complete surrounding rocks 1, and the complete surrounding rocks 1 and surrounding rocks The inner wall of the plastic zone 2 is provided with two linings 12, and a gap is provided between the two; inside the gap, a debris bin 4 is arranged on the inner wall of the complete surrounding rock 1 and the plastic zone 2 of the surrounding rock, A liquid debris layer 3 is arranged inside the debris bin body 4 , and a ceramsite bin body 10 and a water-filled carcass 5 are arranged in the gap between the debris bin body 4 and the second liner 12 . By adopting the above-mentioned lining pressure relief support structure, targeted support can be carried out for specific areas, and the fluid debris layer 3 can independently provide specified support reaction forces to the...

Embodiment 2

[0052] The construction method of the sub-compartment lining pressure relief support structure of any one of the various fillers, it comprises the following steps:

[0053] Step1: Material preparation: Prepare pressure sensor 13, automatic pressure relief valve 6, pressure gauge 7, rubber carcass 17, steel arch frame, waste fluid debris, ceramsite and carcass fluid 18;

[0054] Step2: Make filling package: put the selected waste liquid debris into the flexible package bag 15, and wrap the geotextile bag 16 outside to complete the debris bin 4; wrap a layer of carcass protection on the water-filled carcass 5 Layer 9, fill the carcass fluid 18 from the carcass fluid input port, and ensure good airtightness; after connecting the water-filled carcass 5 with the automatic pressure relief valve 6 and the drain pipe 8, set the automatic pressure relief Threshold of the valve 6, water is injected into the rubber carcass 17 to complete the water-filled carcass; the selected ceramsite i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com