Paper cigarette lozenge and preparation method thereof

A nicotine and paper-based technology, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of large consumption of auxiliary materials and high production cost, and achieve the effects of less consumption of auxiliary materials, low production cost and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

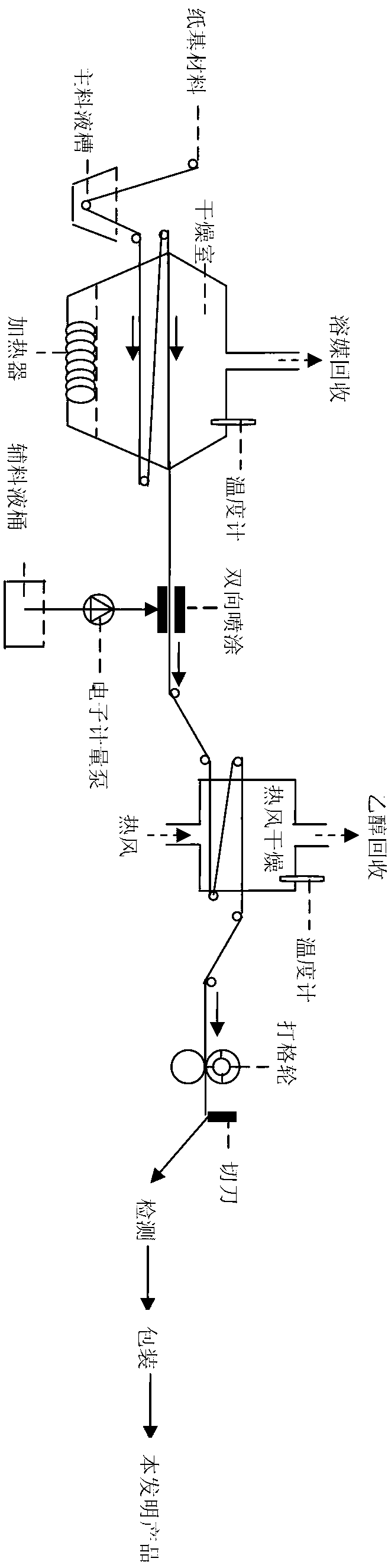

Image

Examples

Embodiment 1

[0033] Proportion (weight ratio): edible nicotine 6%, vegetable paper 80%, maple syrup 10%, orange yellow 2.8%, vitamin C 1.2%.

[0034] Preparation:

[0035] (1) Dissolve 10 grams of edible nicotine in 120ml of petroleum ether, and use it as the main feed liquid for later use.

[0036] (2) Dissolve citrus yellow in 50% ethanol, add maple syrup and vitamin C, and then add 95% ethanol to make an auxiliary liquid with an alcohol content of 80%.

[0037] (3) Put the main material liquid and auxiliary material liquid in the main material liquid tank of the paper machine and the auxiliary material liquid tank of the electronic metering pump respectively, and use vegetable paper to absorb the main material liquid, and the vegetable paper after moisture absorption enters the oven for drying at 85°C.

[0038] (4) The auxiliary material liquid is sprayed on the vegetable paper in two directions through the electronic metering pump, and the semi-finished product is dried by hot air at 80°C with a...

Embodiment 2

[0042] Proportion (weight ratio): 6.4% edible nicotine, 77.5% okara, 13.6% maple syrup, 2% tea green pigment, 0.5% vitamin C.

[0043] Preparation:

[0044] (1) Dissolve 10 edible nicotine in 120ml of chloroform, dissolve completely and serve as the main liquid.

[0045] (2) Dissolve the tea green pigment in 50% ethanol, add maple syrup and vitamin C, and then add 95% ethanol to make an auxiliary liquid with an alcohol content of 75%.

[0046] (3) Put the main material liquid and auxiliary material liquid in the main material liquid tank of the paper machine and the auxiliary material liquid bucket of the electronic metering pump respectively. The main material liquid is absorbed by the bean dregs paper, and the soluble paper after moisture absorption is dried in an oven at 70°C.

[0047] (4) The auxiliary material liquid is sprayed on the bean dregs paper in two directions through an electronic metering pump, and dried by hot air at 80°C to become a semi-finished product with a thickne...

Embodiment 3

[0051] Proportion (weight ratio): nicotine-β-cyclodextrin microcapsules (where nicotine content is 11.5%) 12%, corn paper 74.2%, maple saccharin 11.9%, orange yellow 1.3%, vitamin C 0.6% .

[0052] Preparation:

[0053] (1) Add 100g of nicotine-β-cyclodextrin microcapsules to 120ml of isopropanol to form a suspension as the main feed solution.

[0054] (2) Dissolve citrus yellow in 50% ethanol, add maple syrup and vitamin C, and then add 95% ethanol to make an auxiliary liquid with an alcohol content of 75%.

[0055] (3) Put the main material liquid and auxiliary material liquid in the main material liquid tank of the paper machine and the auxiliary material liquid bucket of the electronic metering pump respectively, and use corn paper to absorb the main material liquid, and the moisture-absorbing corn paper enters the drying oven at 85 ℃.

[0056] (4) The auxiliary material liquid is sprayed on the corn paper in two directions through the electronic metering pump, and the semi-finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com