Method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt

A technology of colored polylactic acid and polylactic acid, which is applied to single-component polyester rayon, adding pigments to spinning solution, adding dyes to spinning solution, etc., can solve the problem of environmental damage, low temperature resistance, Constraints and other issues to achieve the effect of ensuring consistency, avoiding color difference, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

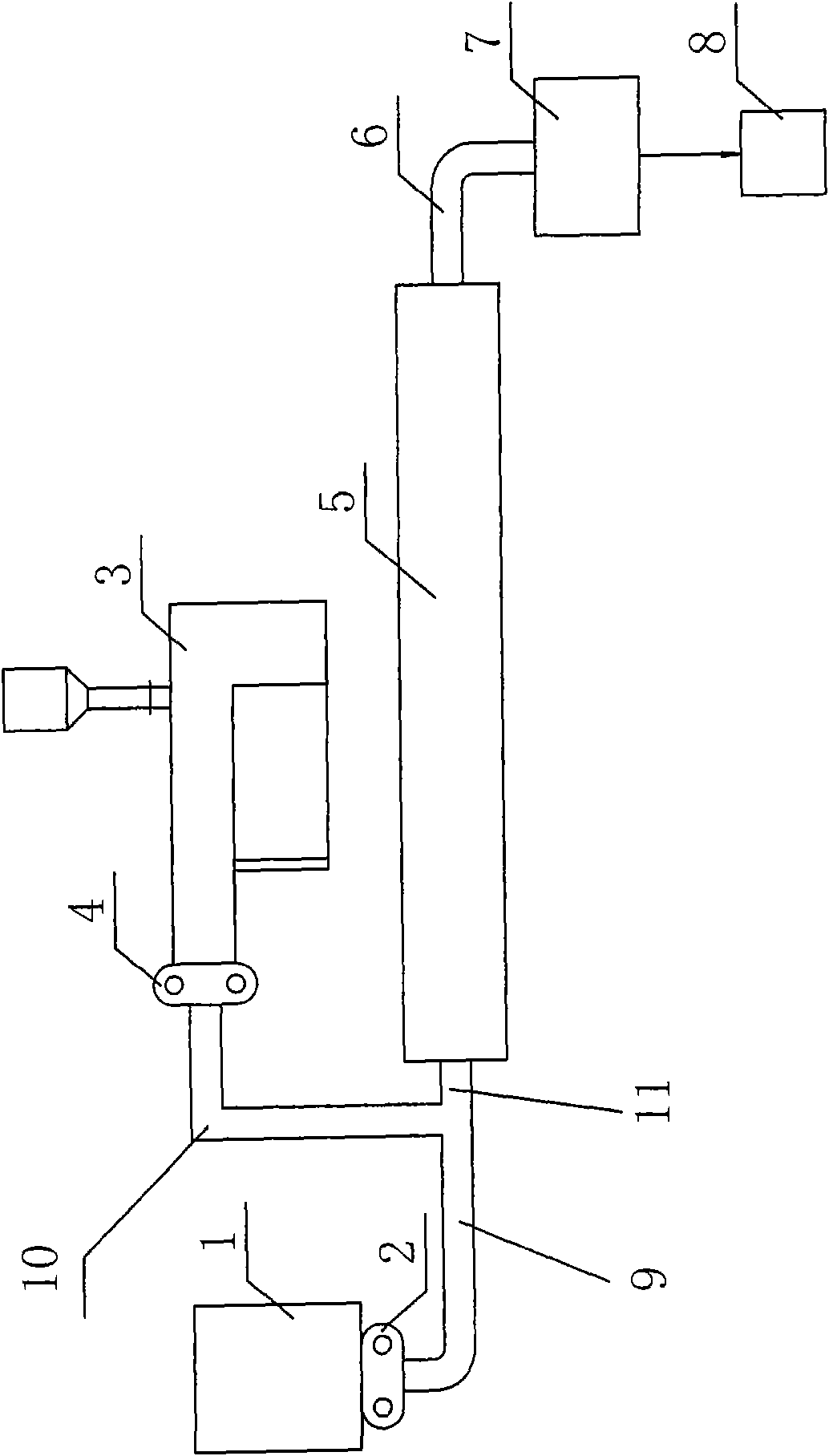

[0023] see figure 1 , from the end of the polymerization reaction of the polylactic acid polymerization reaction device, a viscous polymer with a process temperature of 170 ° C is obtained. This polymer is the off-white polylactic acid polymerization melt. The first discharge pump 2 at the discharge port of the polylactic acid polymerization melt post-processing device, that is, the termination device 1, is connected between the discharge port of the first discharge pump 2 and the feed port 11 of the melt mixing device 5 The first melt delivery pipeline 9 is continuously transported to the melt mixing device 9 with a positive pressure of 35 MPa at a process temperature of 170 ° C and maintained at 170 ° C. At the same time, the screw extruder 3 The second discharge pump 4 at the discharge port of the screw extruder passes the colored polylactic acid melt with the same process temperature of 170 ° C after the polylactic acid color masterbatch is thermally melted by the screw ex...

Embodiment 2

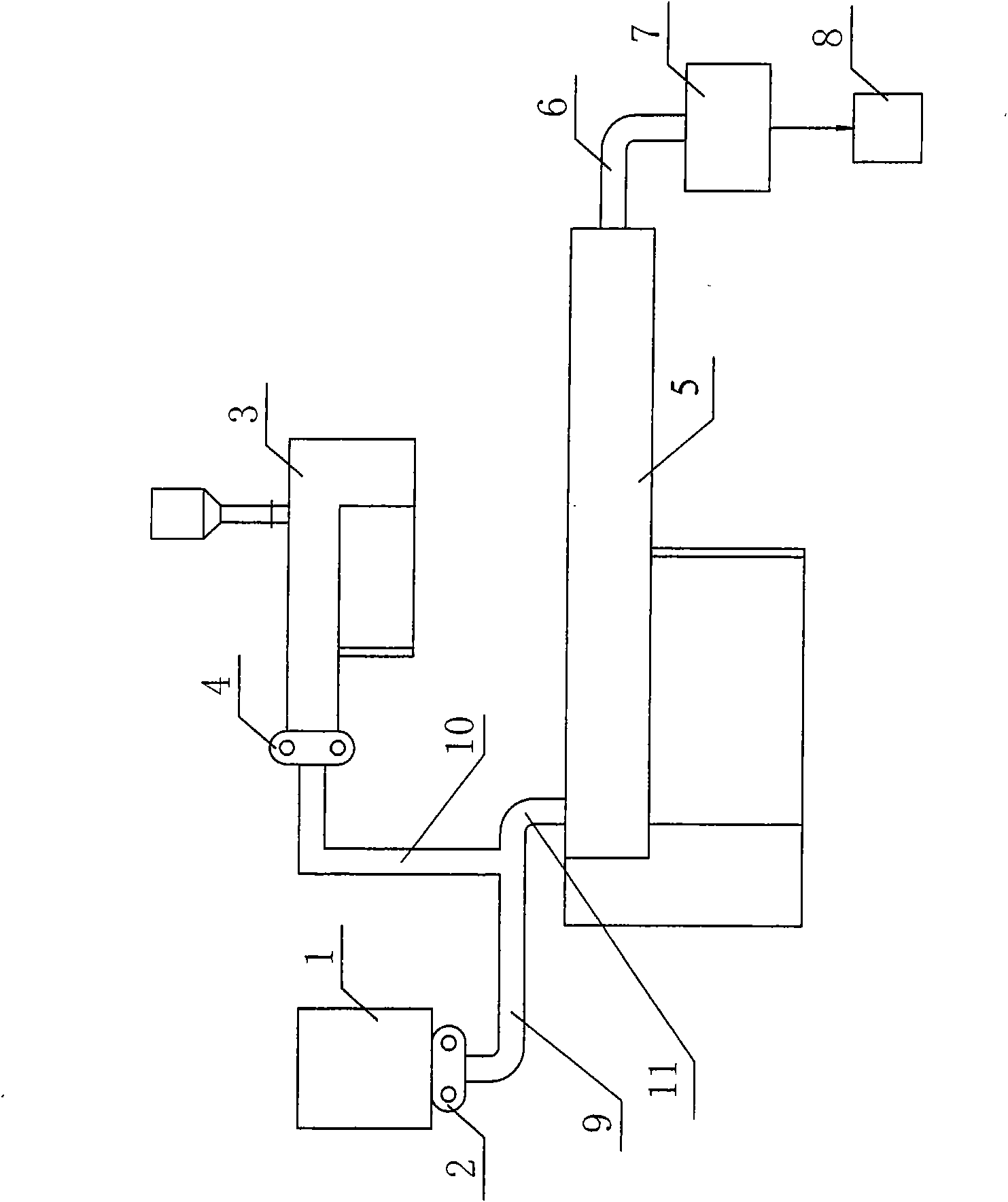

[0029] see figure 2 , the process temperature is 190 ℃ from the end of the polymerization reaction of the polylactic acid polymerization reaction device to obtain a viscous polymer with a process temperature of 190 ° C. This polymer is the off-white polylactic acid polymerization melt. The first discharge pump 2 at the discharge port of the polylactic acid polymerization melt post-processing device, that is, the termination device 1, is connected between the discharge port of the first discharge pump 2 and the feed port 11 of the melt mixing device 5 The first melt delivery pipeline 9 is continuously transported to the melt mixing device 9 with a positive pressure of 20 MPa at a process temperature of 190 ° C and maintained at 190 ° C. At the same time, the screw extruder 3 The second discharge pump 4 at the discharge port of the screw extruder passes the colored polylactic acid melt with the same process temperature of 190 ° C after the polylactic acid color masterbatch is t...

Embodiment 3

[0034] see figure 1 A viscous polymer with a process temperature of 250°C is obtained from the polymerization reaction of the polylactic acid polymerization reaction device. This polymer is the off-white polylactic acid polymerization melt. The first discharge pump 2 at the discharge port of the polylactic acid polymerization melt post-processing device, that is, the termination device 1, is connected between the discharge port of the first discharge pump 2 and the feed port 11 of the melt mixing device 5 The first melt conveying pipeline 9 is continuously transported to the melt mixing device 9 with a positive pressure of 10 MPa at a process temperature of 250 ° C and maintained at 250 ° C. At the same time, the screw extruder 3 The second discharge pump 4 at the discharge port of the screw extruder passes the colored polylactic acid melt with the same process temperature of 250 ° C after the polylactic acid color masterbatch is thermally melted by the screw extruder through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com