Light-emitting chip gear dividing method according to different color coordinate areas

A technology of light-emitting chips and color coordinates, which is applied in sorting and other directions, can solve the problems of poor color consistency of the display screen and small number of color coordinates, and achieve color consistency assurance, small number of bins, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

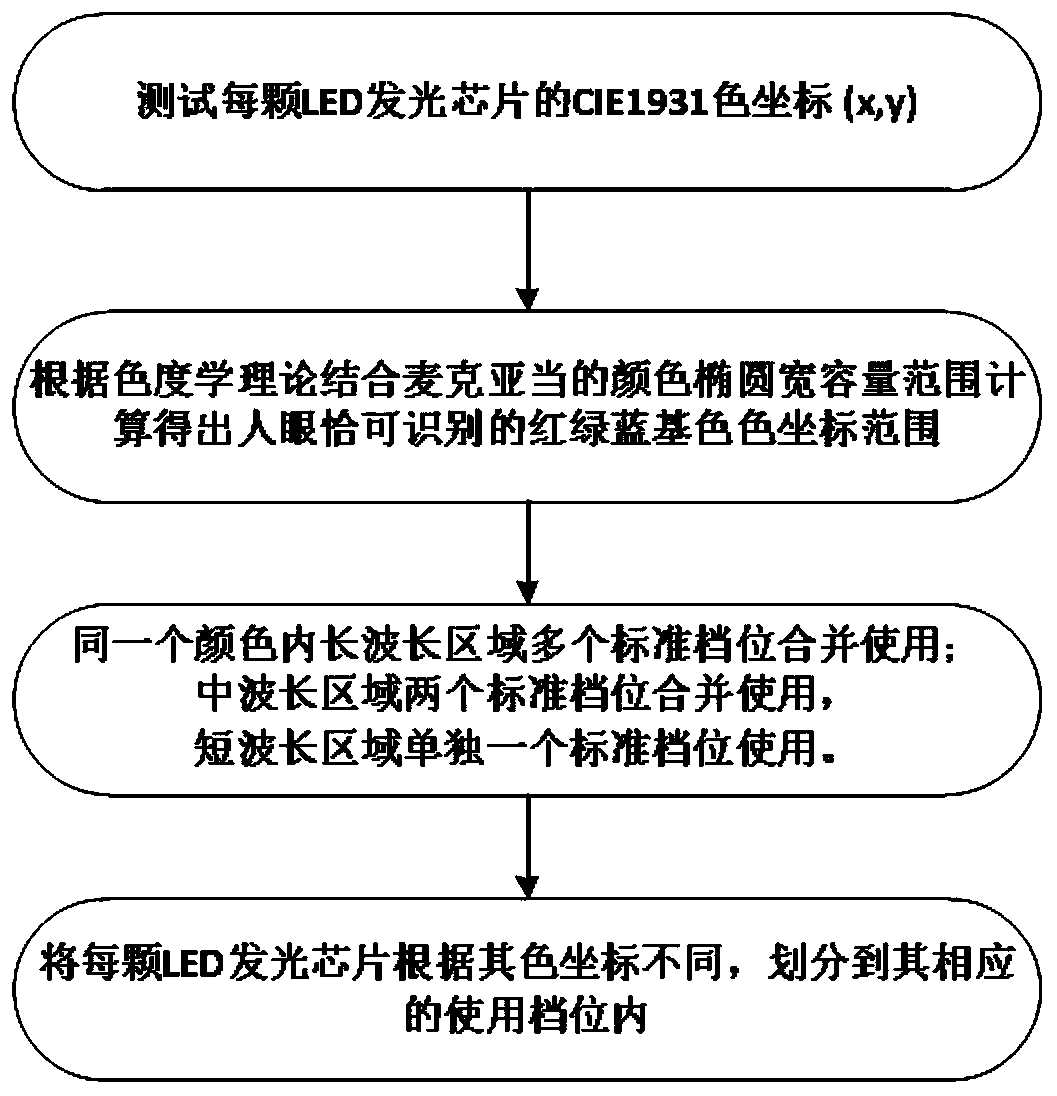

Method used

Image

Examples

Embodiment 1

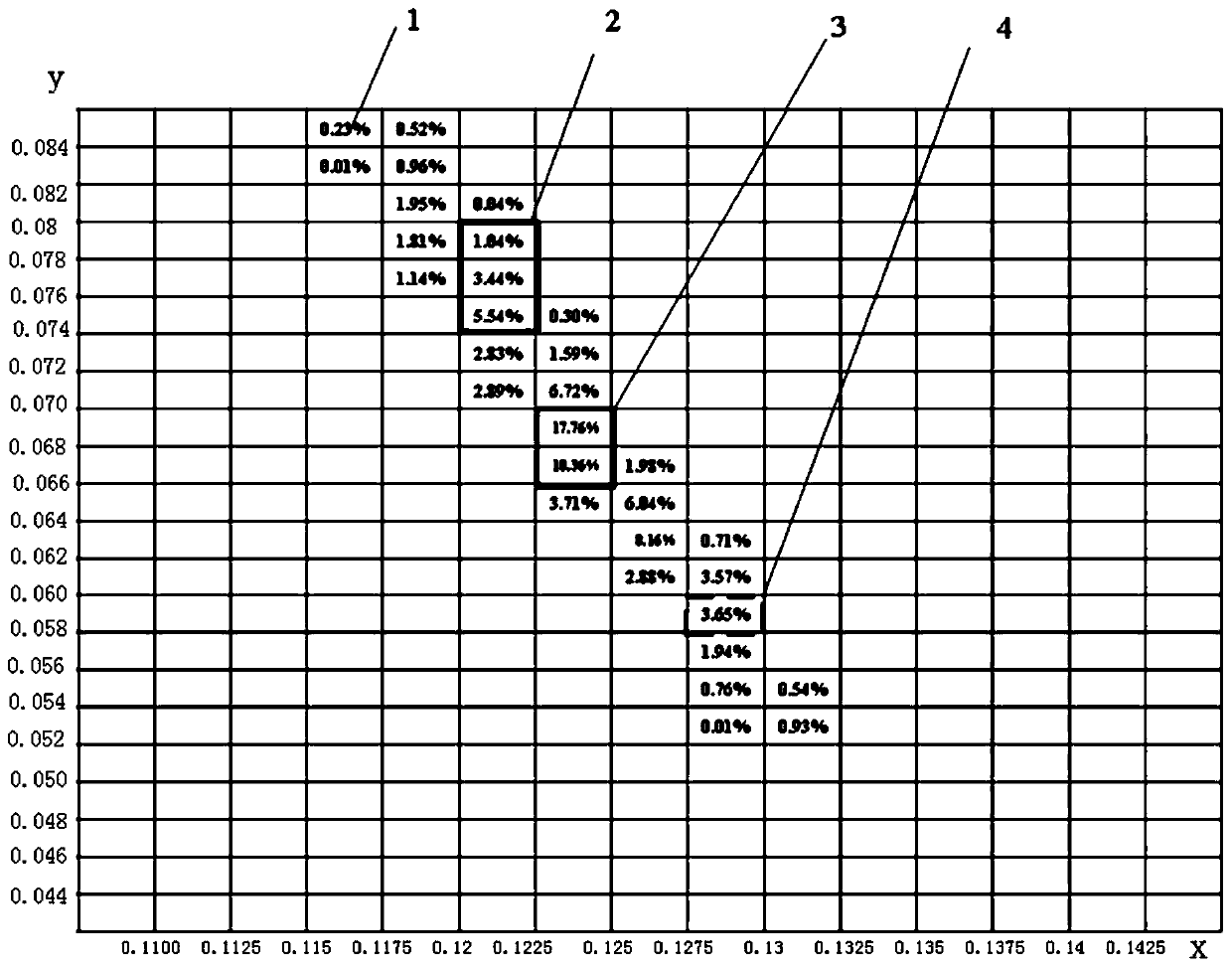

[0023] During the solid crystal operation, grab the light-emitting chips in a standard gear in the short-wavelength region of each color and arrange them on a unit module. For example, during the solid crystal operation, red grabs a light-emitting chip in a standard gear, green grabs a light-emitting chip in a standard gear, and blue grabs a light-emitting chip in a standard gear. figure 2 The short-wavelength region represented by grid 4 with the black dotted line in the middle uses the light-emitting chip in the gear. Modules with the same parameters are combined into one display screen. The display screen produced in this way has high color purity, no chromaticity problem, and good color consistency.

Embodiment 2

[0025] During the solid crystal operation, red grabs a light-emitting chip in a standard gear, green grabs a light-emitting chip in a standard gear, and blue grabs a light-emitting chip in a standard gear. figure 2 The long-wavelength region represented by the middle black solid line grid 2 uses the light-emitting chip in the gear. In this way, modules with the same parameters are combined into one display screen. Although the blue color of the display screen made in this way is a combination of the three standard gears, the human eye is not sensitive to the resolution of the blue long-wavelength region, so the display screen made in this way will not have chromaticity problems. And it effectively reduces the number of blue bins, which is convenient for production management and engineering operations.

Embodiment 3

[0027] During the solid crystal operation, red grabs a light-emitting chip in a standard gear, green grabs a light-emitting chip in a standard gear, and blue grabs a light-emitting chip in a standard gear. figure 2 The middle black solid line grid 3 represents the light-emitting chip in the middle wavelength region. In this way, modules with the same parameters are combined into one display screen. Although the blue color of the display screen made in this way is a combination of two standard gears, the human eye's ability to distinguish the mid-wavelength region of blue is moderate, so the display screen made in this way will not have chromaticity problems and is effective. The number of blue bins is reduced, which is convenient for production management and engineering operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com