Water-based coating process for high-brightness silver wheel

A coating process and water-based technology, applied in the field of water-based coating process for high-gloss silver wheels, can solve the problems of non-compliance with the green sustainable development strategy, poor powder coating, and obvious color difference, so as to ensure the consistency of appearance color and paint film Reduced reliability, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

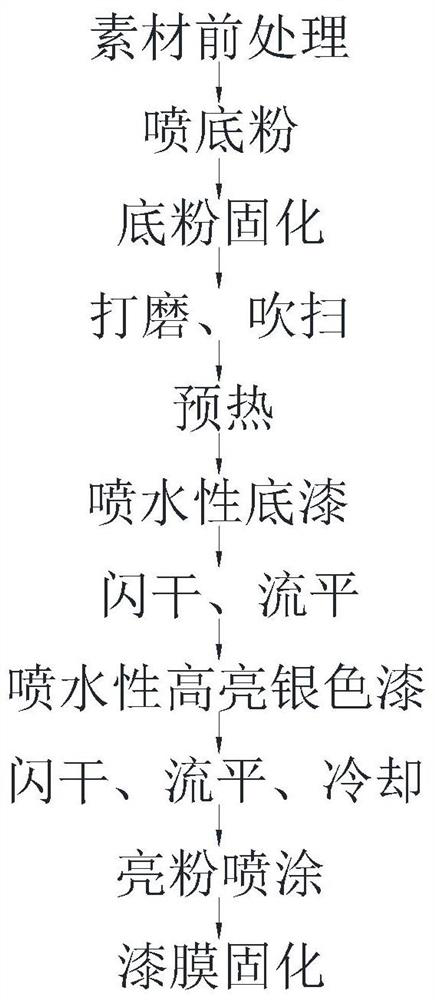

Method used

Image

Examples

Embodiment 1-2

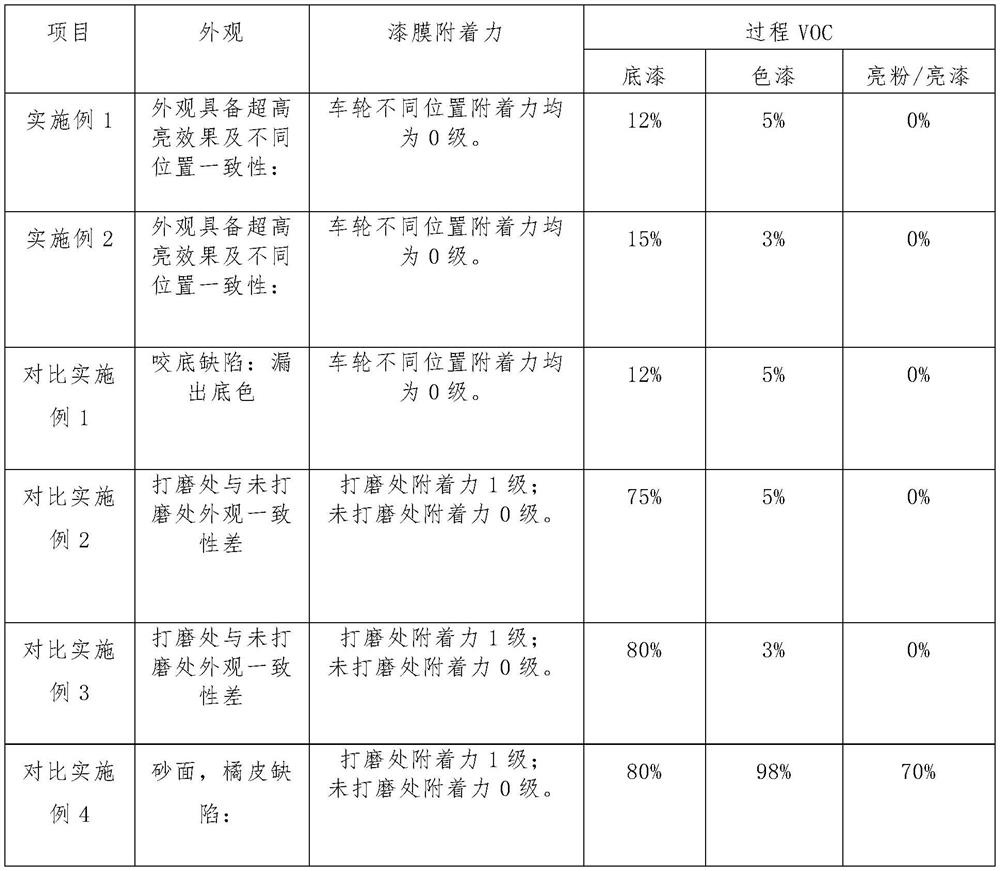

[0090] Example 1-2, Comparative Example 1-3 Appearance, paint film adhesion, process VOC are compared as follows:

[0091]

[0092] Analysis of Example 1 and Comparative Example 1 shows that the flash-off temperature is low, the water content of the primer after flash-off is high, and the high-water-content electroplating silver is sprayed on the primer interface, causing the water-based high-brightness silver and the water-based primer to bite the bottom, and the appearance is poor.

[0093] Analysis of Examples 1, 2 and Comparative Examples 2 and 3 shows that the use of water-based primer for full spray can solve the problem of blackening in the unpolished area, ensure the consistency of product appearance, and can effectively reduce construction VOC.

[0094] Analysis of Example 1 and Comparative Example 4 shows that the use of pure polyester powder and high-leveling water-based black matrix can solve the problem of orange peel of epoxy polyester powder, especially in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com