Method and device for directly preparing polylactic acid foam product from polylactic acid polymer melt

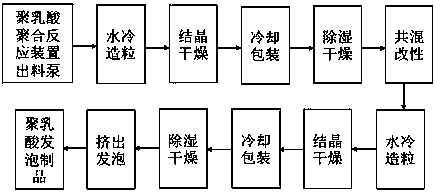

A polylactic acid foaming and polymerizing device technology is applied in the field of directly preparing foamed products from polylactic acid polymer melt, which can solve the problems of complex procedures and high costs, and achieve the effects of ensuring quality, low porosity and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

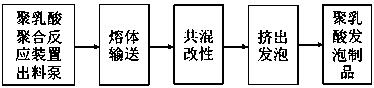

[0076] Example 1 The method of directly preparing polylactic acid foamed products from polylactic acid polymer melt

[0077] refer to Figure 3-6 The method for directly preparing polylactic acid foamed products from the polylactic acid polymer melt of the present invention comprises the following steps:

[0078] Step 1: Polylactic acid melt preparation

[0079] After the main raw material lactide is heated and melted, it is mixed with the catalyst stannous octoate and the initiator isooctyl alcohol to start the polymerization reaction. The mass ratio of lactide: stannous octoate: isooctyl alcohol is 7500:1:13, and the polymerization temperature 235°C. After the polymerization reaction is completed, a chain terminator 2-ethyloctanoic acid is added to terminate the reaction, and the mass ratio of lactide to terminator is 75000:1. After devolatilization and monomer removal, a polylactic acid melt with a melt flow index of about 3.7g / 10min (190°C, 2.16kg) was obtained, with a ...

Embodiment 2-3

[0103] Example 2-3 Method for directly preparing polylactic acid foamed products from polylactic acid polymer melt

[0104] Examples 2-3 adopt the same foaming process as that of Example 1, except that the proportions of each component in raw materials and additives are different, and the temperature and head pressure process parameters are controlled differently. The process conditions are shown in Table 1, and the results are shown in Table 2.

[0105] Table 1

[0106]

Embodiment 4

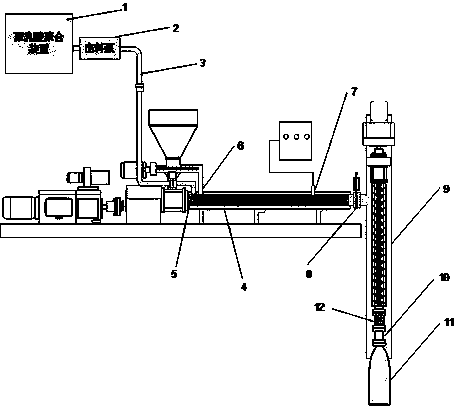

[0121] Example 4 A device for directly preparing foam from polylactic acid polymer melt

[0122] The following is a detailed description of the polylactic acid foamed product preparation device of the present invention:

[0123] refer to Figure 3-6 , the device for directly preparing foam from the polylactic acid polymerization melt of the present invention, comprising: a polylactic acid polymerization device 1, a first-stage twin-screw extruder 4 and a second-stage single-screw extruder 9, the first-stage twin-screw extruder Extruder 4 is mainly used for uniform mixing of polylactic acid melt and foaming aid, and preliminary mixing with foaming gas, and the second-stage single-screw extruder 9 is mainly used for mixing polylactic acid / foaming aid The mixing and cooling of the body and the foaming gas reduces the temperature to a range suitable for foaming; the first-stage twin-screw extruder 4 and the second-stage single-screw extruder 9 can be vertically arranged, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com