Grain protein-based formulations and methods of using same

A technology of grain protein and gluten, which is applied in vegetable protein processing, animal feed molding or processing, application, etc., can solve problems such as resin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

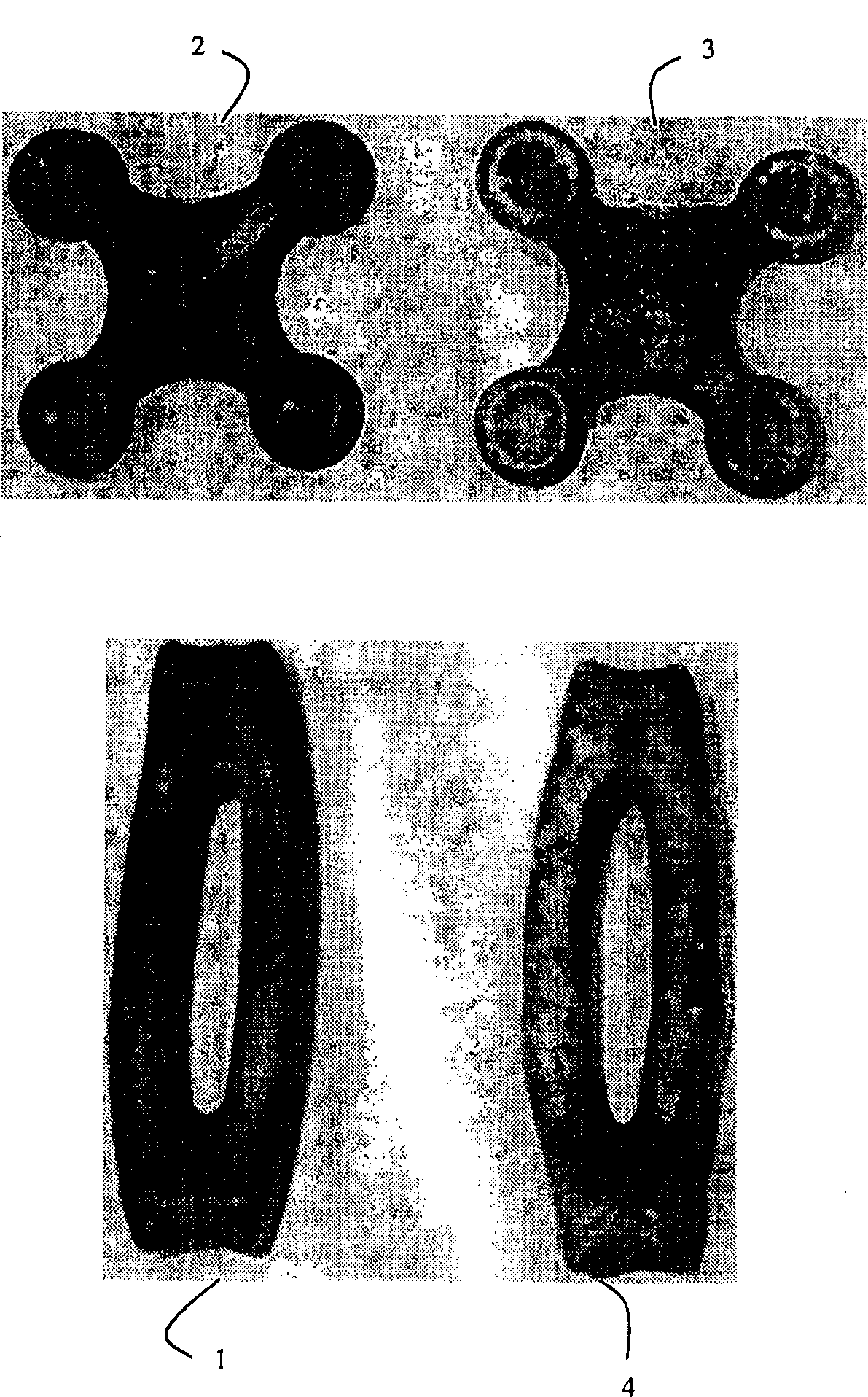

Image

Examples

Embodiment 1

[0043] Table 1 shows resin formulations containing 8% hydrolyzed wheat gluten (HWG 2009, produced by MGP Ingredients, Inc.). Resin pellets were produced using an 85 mm twin-screw extruder (TX-85 manufactured by Wenger) with a hot face diecutter. The powder-liquid mixture in the extruder is mixed at a melting temperature not exceeding 95°C to avoid thermal denaturation of proteins. After the die face cuts the pellets, the resin pellets are air conveyed to a cooler and packed.

[0044] Examined after 4 months, the presence of 8% hydrolyzed wheat gluten helped to increase the shelf life of the resin pellets. The molded article exhibited the same appearance and physical properties as those produced immediately after the resin was prepared.

[0045] Table 1

[0046] Element

Embodiment 2

[0048] Table 2 shows resin formulations containing 5% hydrolyzed wheat gluten-emulsifier complex. By adding Panodan TM SDK emulsifier (supplied by Danisco) was added to the HWG 2009 protein dispersion to prepare the hydrolyzed wheat gluten-emulsifier complex and spray dried. The hydrolyzed protein-emulsifier complex contained 25% Panodan in the spray-dried product TM SDK (emulsifier).

[0049] Resin pellets were produced using an 85 mm twin-screw extruder (TX-85 manufactured by Wenger) with a hot face die cutter. The powder-fluid mixture in the extruder is mixed at a melting temperature not exceeding 95°C to avoid thermal denaturation of proteins. After the die face cuts the pellets, the resin pellets are air conveyed to a cooler and packed.

[0050] Examined after 5 months, the presence of 5% hydrolyzed wheat gluten-emulsifier complex helped to increase the shelf life of the resin particles. The molded article exhibited the same appearance and physical properties as tho...

Embodiment 3

[0054] Table 3 shows formulations containing 3.5% liver digest product (OptimizorTM CHX-base, produced by Applied Food Biotechnology, Inc.). CHX-Base liver digest is a form of a complex of hydrolyzed protein, hydrolyzed protein derivatives, and an emulsifier, wherein the protein is poultry liver and the emulsifier is hydrolyzed animal fat. The hydrolyzed protein derivative is the reaction product of hydrolyzed protein and maltodextrin to enhance flavor. Resin pellets were produced using an 85 mm twin-screw extruder (TX-85 manufactured by Wenger) with a hot face die cutter. The powder-fluid mixture in the extruder is mixed at a melting temperature not exceeding 95°C to avoid thermal denaturation of proteins. After the die face cuts the pellets, the resin pellets are air conveyed to a cooler and packed.

[0055] Checked after 5 months, the 3.5% CHX-Base liver digest helped improve the shelf life of the resin pellets. The molded article exhibited the same appearance and physic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com