Fiber sheets and structures comprising fiber sheets

A fiber sheet, fiber technology, applied in the direction of organic non-cellulose fiber, synthetic cellulose/non-cellulose material pulp/paper, inorganic fiber/sheet, etc., can solve the limited water resistance acceptance and strength performance, user experience Poor performance and preference, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] Manufacture of fiber sheets

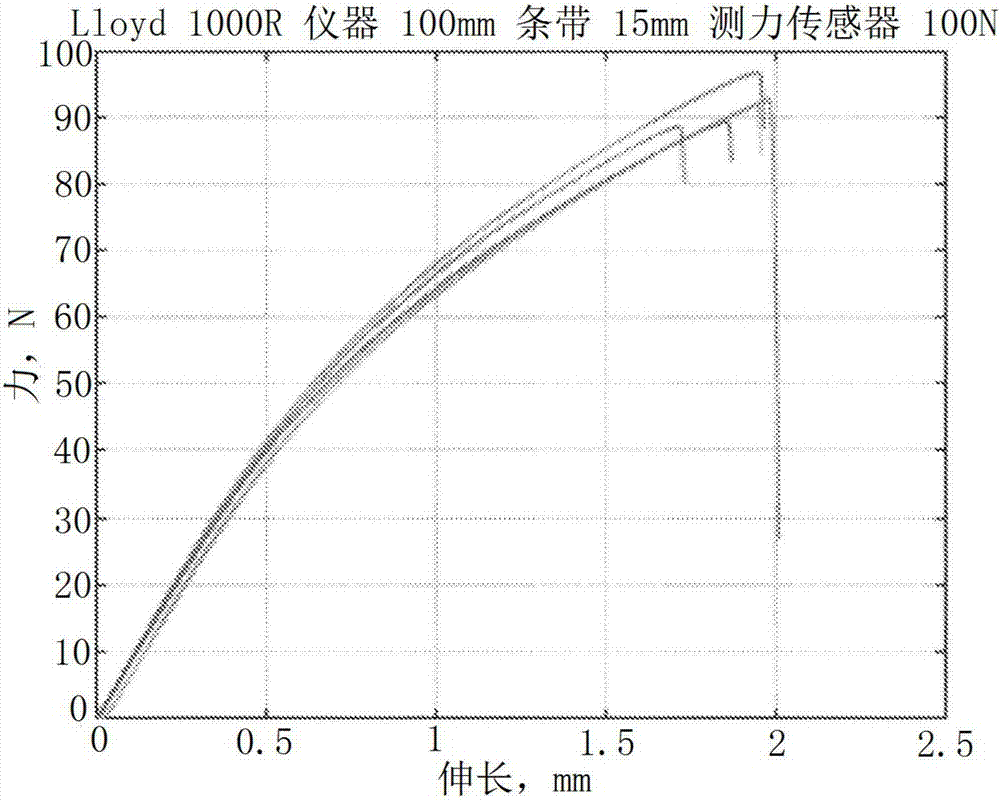

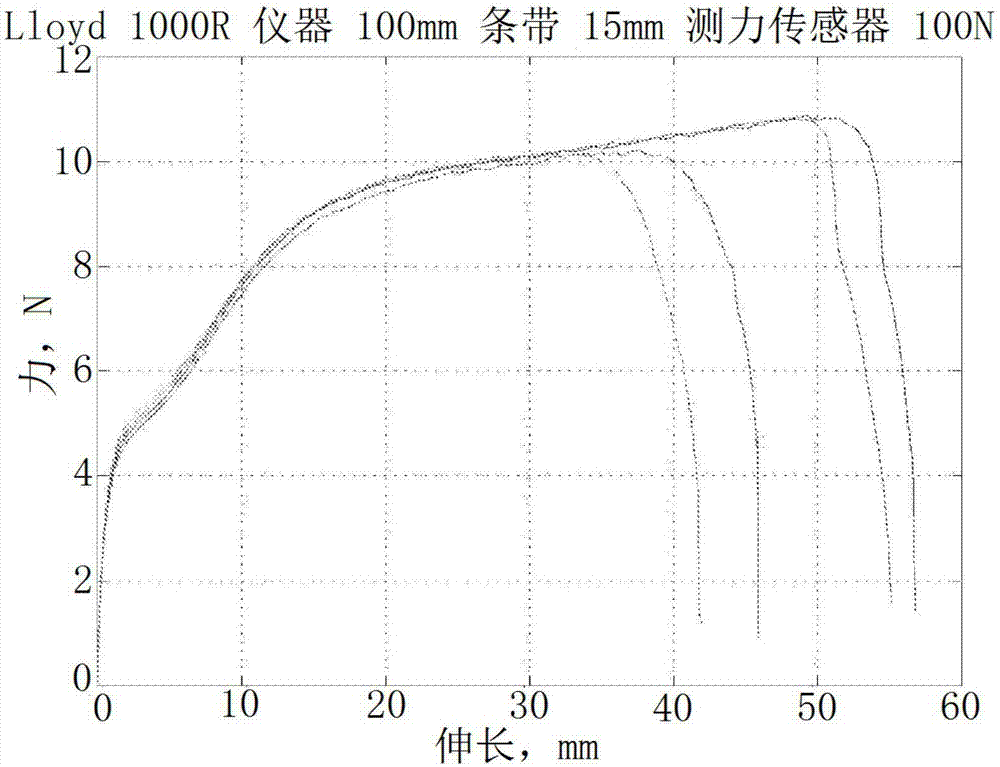

[0167] Fiber sheets were fabricated on a laboratory scale as follows. Softwood fibers and bicomponent synthetic fibers (PES / PE) were mixed in a ratio of 70:30 into a prefabricated foam made of water and polyvinyl alcohol containing a soft latex (polyacrylic acid). Foam lay-up handsheets are made using methods and apparatus employed in the fiberglass industry. The fibrous foam was decanted into handsheet molds and filtered through a mesh using a vacuum chamber. The filtered sheet and mesh were then separated from the mould and pre-dried on a suction table. The suction table has a 5mm width slot which sucks air through the sheet under a vacuum of ~0.2 bar. The series of graphs presented in Figure 8 illustrate the workflow used in the lab-scale development work.

[0168] After drying under constant atmosphere, the sheets were calendered at a nip pressure of 80 bar and a rolling temperature of 60°C using a Gradek laboratory calender.

[01...

Embodiment 2

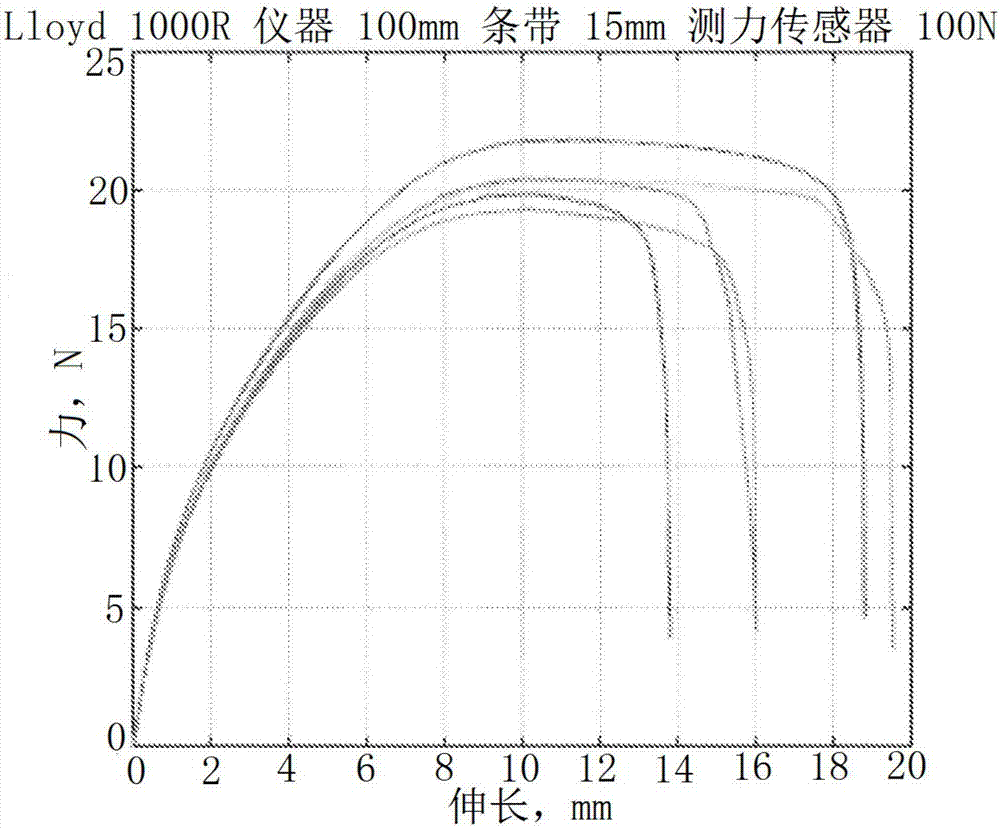

[0179] Manufacture of bags from fiber sheet

[0180] Fabrication of bags made of fiber sheets is as follows. Fibrous sheets were obtained using the foam lay-up method as described in Example 1. Softwood (pine) fibers and bicomponent synthetic fibers (PES / PE) were mixed in a ratio of 70:30 into a prefabricated foam made of water and polyvinyl alcohol containing a soft latex (polyacrylic acid). After drying under constant atmosphere, the sheet was calendered. Obtained with 10 wt% PVA and latex (total) and had 30 g / m 2 and 80g / m 2 Gram weight fiber sheet. Heat-sealed bags made from fiber sheets. The bag was repeatedly compressed into a pouch and reopened to its original shape, no change in appearance was observed and no damage was observed. The bag can be folded like a sock. exist Figure 9A A photo of the bag is shown in Figure 9B The tear strengths of plastic bags, paper bags, paper and bags made in this example are shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com