Water-based metal cutting liquid

A base metal, cutting fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high environmental hazards, troublesome waste liquid treatment, high base oil content, and achieve good thermodynamic stability, strong synergistic function, and system. good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

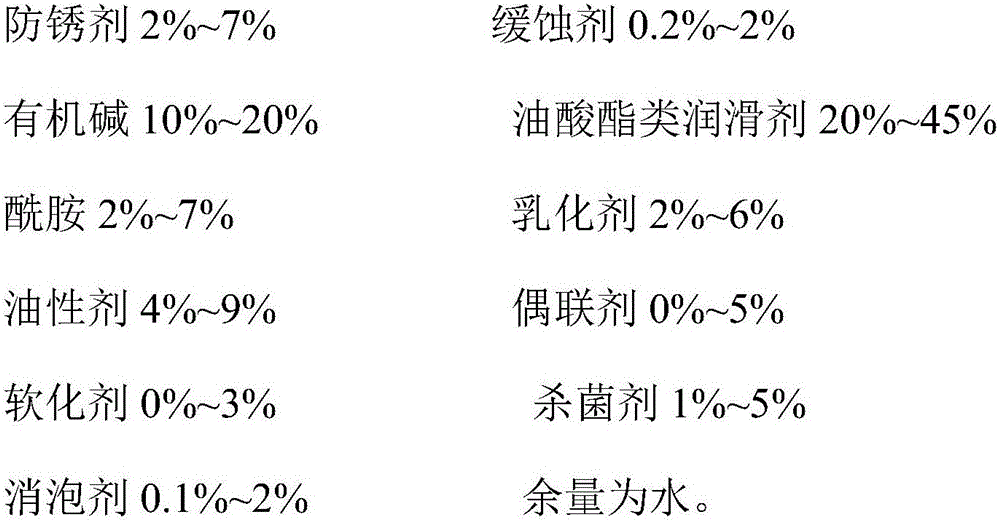

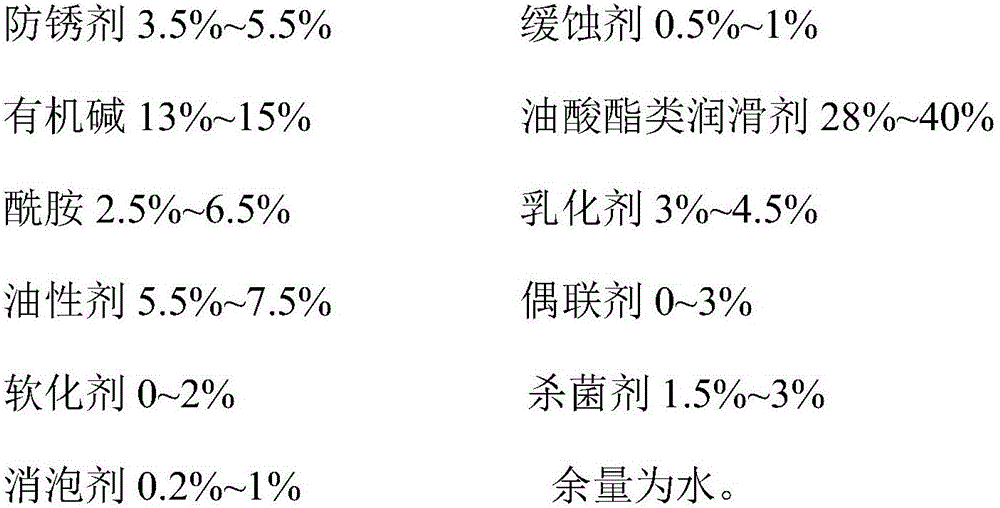

[0036] Embodiment 1, a kind of water-based cutting fluid, is made of the raw material of following mass percentage:

[0037] Rust inhibitor: undecanedioic acid 5.5%

[0038] Corrosion inhibitor: Benzotriazole 1%

[0039] Organic base: triethanolamine 13%, dicyclohexylamine 2%

[0040] Lubricants: 18% isooctyl oleate, 11% tetrameric ricinoleate

[0041] Amide: Tall Oil Monoethanolamide 3.5%

[0042] Emulsifier: AEO3 0.7%, AEO9 2.3%

[0043] Oily agent: dimer acid (dimer fatty acid) 6%

[0044] Coupling agent: glycerin 2%

[0045] Softener: Tetrasodium EDTA 1%

[0046] Fungicide: Benzisothiazolinone 2%

[0047] Antifoaming agent: silicone emulsion 0.2%

[0048] Deionized water: balance

[0049] The preparation method of water-based cutting fluid comprises the following steps:

[0050] A. First add softener to deionized water, dissolve to obtain transparent demineralized water, then add rust inhibitor, corrosion inhibitor, organic base, stir and dissolve to obtain trans...

Embodiment 2

[0054] Embodiment 2, a kind of water-based cutting fluid, is made of the raw material of following mass percentage:

[0055] Rust inhibitor: undecanedioic acid 4.5%

[0056] Corrosion inhibitor: Tolyltriazole 1%

[0057] Organic base: triethanolamine 12%, monoethanolamine 2%

[0058] Lubricants: Neopentyl Glycol Dioleate 18%, Tetraricinoleate 10%

[0059] Amide: Tall Oil Diethanolamide 3.5%

[0060] Emulsifier: AEO3 2.3%, AEO9 1.1%

[0061] Oil agent: epoxy oleic acid 1%, dimer acid 5%

[0062] Coupling agent: ethylene glycol 3%

[0063] Softener: Tetrasodium EDTA 1%

[0064] Fungicide: Hexahydrotriazine 2%

[0065] Defoamer: Propylene Glycol Block Polyether 1%

[0066] Deionized water: balance

Embodiment 3

[0067] Embodiment 3, a kind of water-based cutting fluid, is made of the raw material of following mass percentage:

[0068] Rust inhibitor: dodecanedioic acid 5.5%

[0069] Corrosion inhibitor: Benzotriazole 0.5%

[0070] Organic base: triethanolamine 11%, monoethanolamine 3%, dicyclohexylamine 2.0%

[0071] Lubricants: Pentaerythritol Oleate 19%, Tetraricinoleate 12%

[0072] Amide: Diisopropanolamide 3%

[0073] Emulsifier: AEO3 1.2%, AEO9 1.6%

[0074] Oily agent: 1% oleic acid, 6% dimer acid

[0075] Softener: Tetrasodium EDTA 2%

[0076] Fungicide: n-butylbenzisothiazolinone 2%

[0077] Antifoaming agent: silicone emulsion 0.2%

[0078] Deionized water: balance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com