Patents

Literature

32results about How to "Comprehensive lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene glycol monooleate fully-synthetic cutting fluid and preparation method thereof

ActiveCN102776060AComprehensive lubricationExtend the life cycleLubricant compositionPolyethylene glycolMaterials science

The invention relates to a cutting fluid for metal processing, and particularly relates to a polyethylene glycol monooleate fully-synthetic cutting fluid and a preparation method thereof. Polyethylene glycol monooleate is used as a lubricating agent, and borate generated by boric acid and monoethanolamine and triazine amino-acid ester are combined to form an anti-rust component which has better anti-rust property, thus solving the defects of poor lubricating property, easy deterioration and smelliness and short service life of polyethylene glycol lubricating agents, polyether lubricating agents, oleic acid soap lubricating agents and sulfonated caster oil lubricating agents, and further achieving a corrosion inhibition and synergy function by adding a proper amount of benzotriazole copper corrosion inhibitor and other anti-rust agents. The fully-synthetic cutting fluid prepared from the raw materials is complete in property, has excellent hard water resistance, can be used under a high hard water environment, is high in pH buffer capacity, is stable in quality, has excellent lubricating, anti-rust and anti-corrosion functions, belongs to an environment-friendly product, can be biodegraded, is suitable for various kinds of machining, and is especially suitable for various machining processes of a grinder.

Owner:温州宝罗润滑材料有限公司

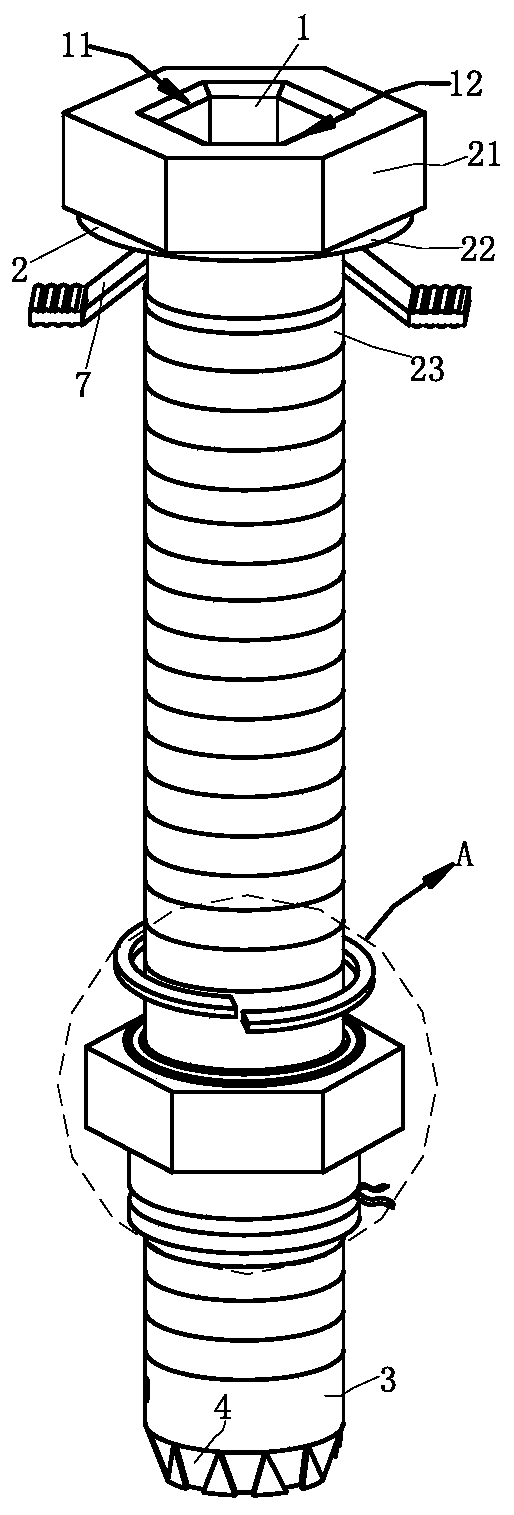

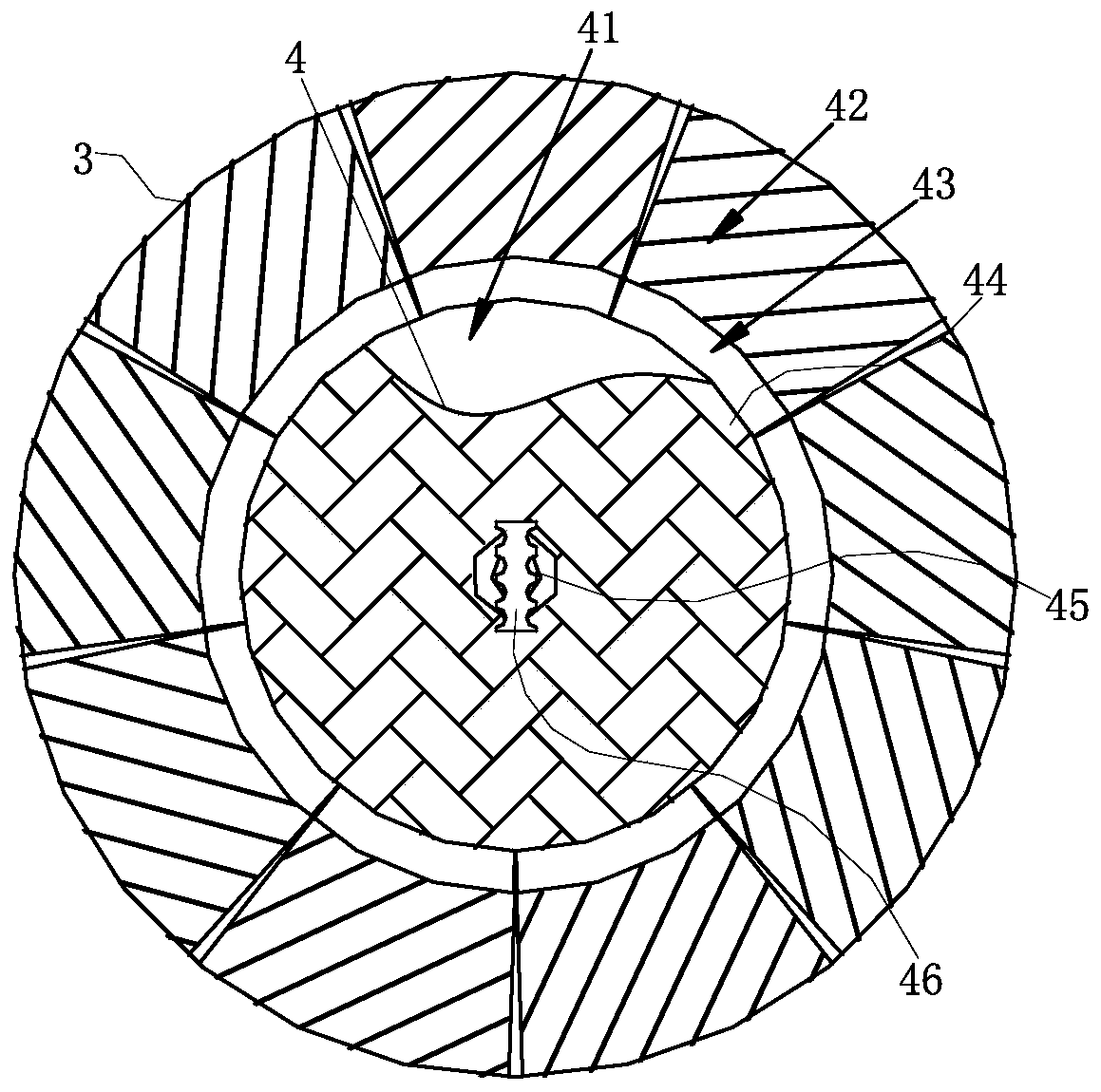

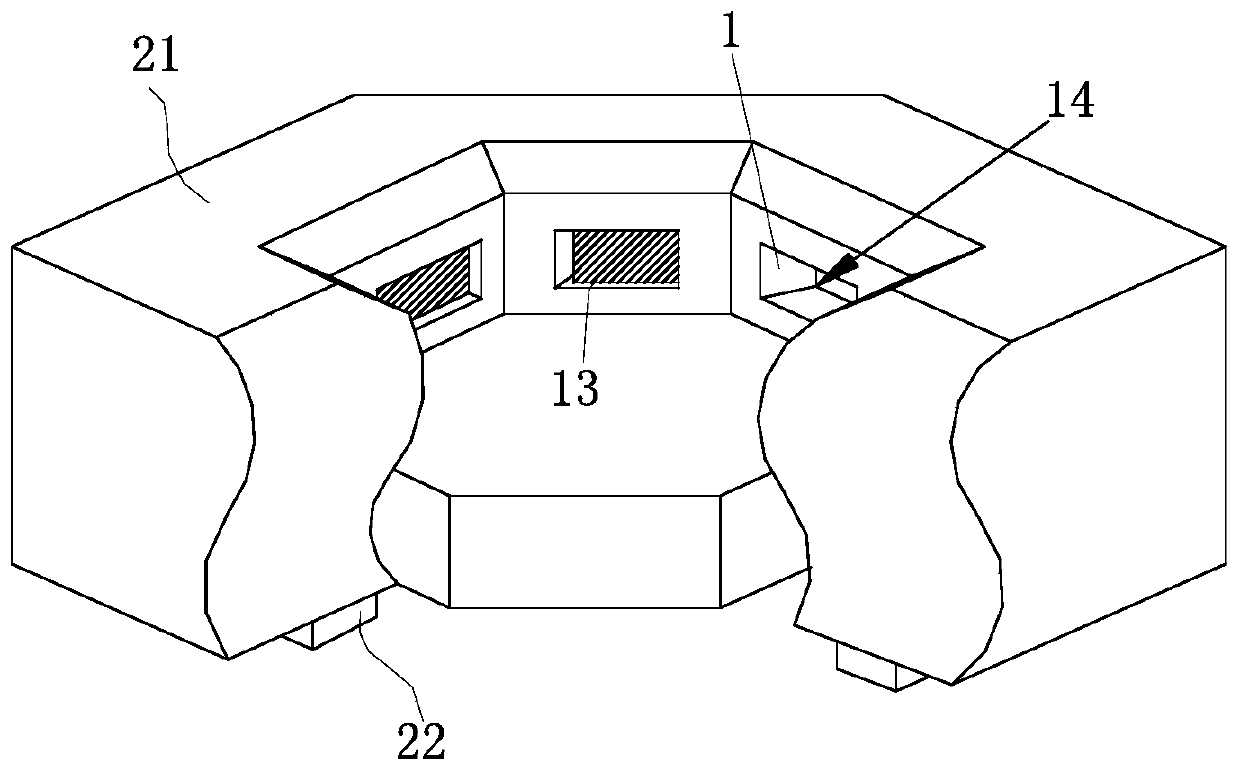

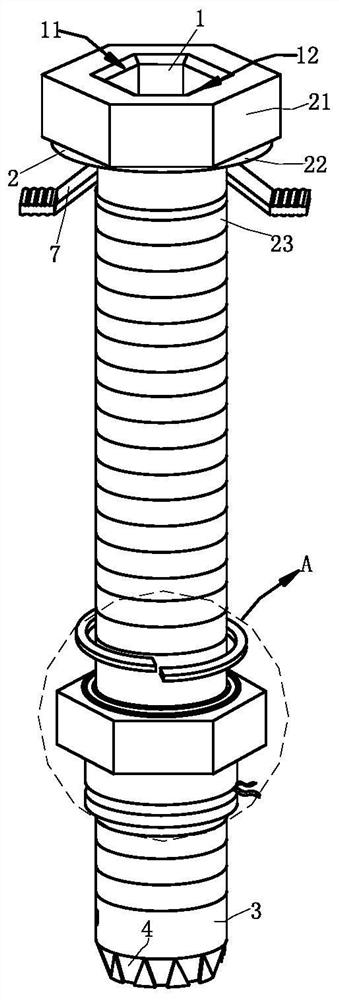

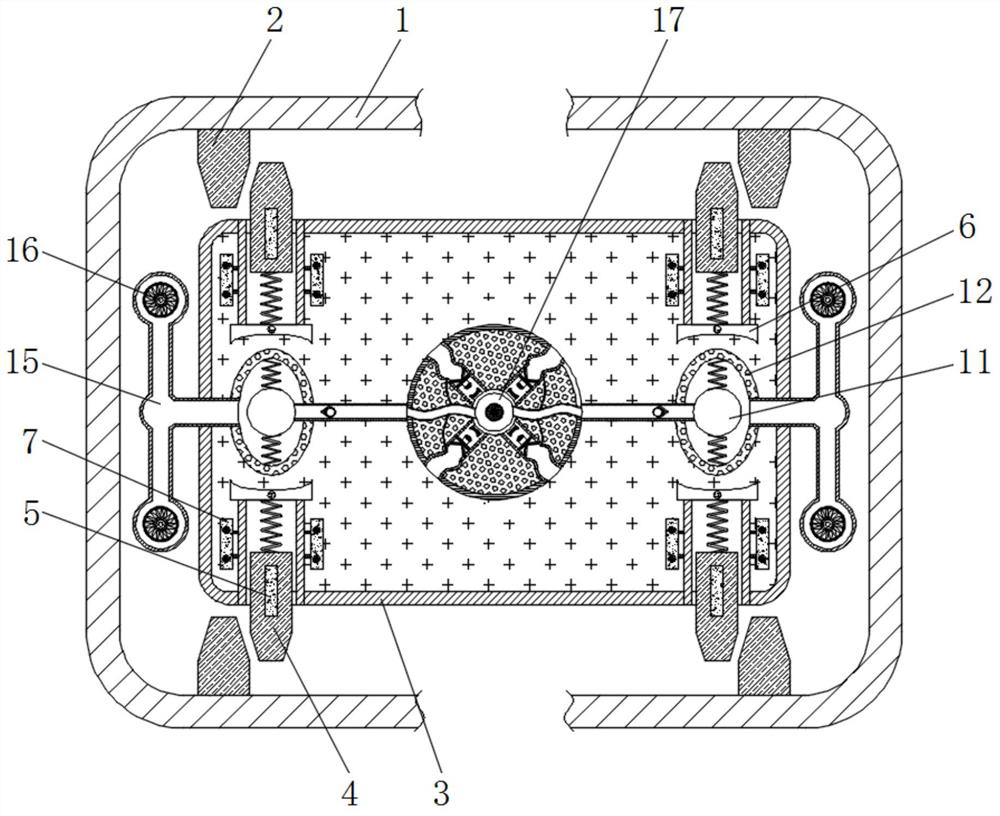

Inner-hexagon screw fastener

The present invention relates to the field of fasteners, in particularly to an inner-hexagon screw fastener, comprising: a disassembling mechanism, a connecting mechanism, a guide post, a lubricatingmechanism, a protection mechanism, a water-proofing mechanism, a pushing mechanism and an oiling mechanism; the pushing mechanism is installed inside a screw rod; when a fixing hole of a plate is toolarge to affect the stability of fixing, the screw rod is used to pass through the plate to make a platen in contact with the plate; when two connecting plates are opened from each other, a push rod is pushed towards a rubber cup to jack up the rubber cup, thereby making lubricating oil flow out from the rubber cup so as to lubricate a screw rod and facilitate installation; when flowing out from the rubber cup, the lubricating oil can flow from an oil inlet in the sidewall of the screw rod and into an oil chamber; when disassembled, a nut is loosened to make the platen and the plate separate from each other, thus the angle between the two connecting plates becomes smaller; and the push rod moves towards a fixed block, the rubber cup restores, and a press rod extrudes oil from the oil chamber to the sidewall of the screw rod for lubrication, so it is convenient to unscrew the nut.

Owner:山东九佳紧固件股份有限公司

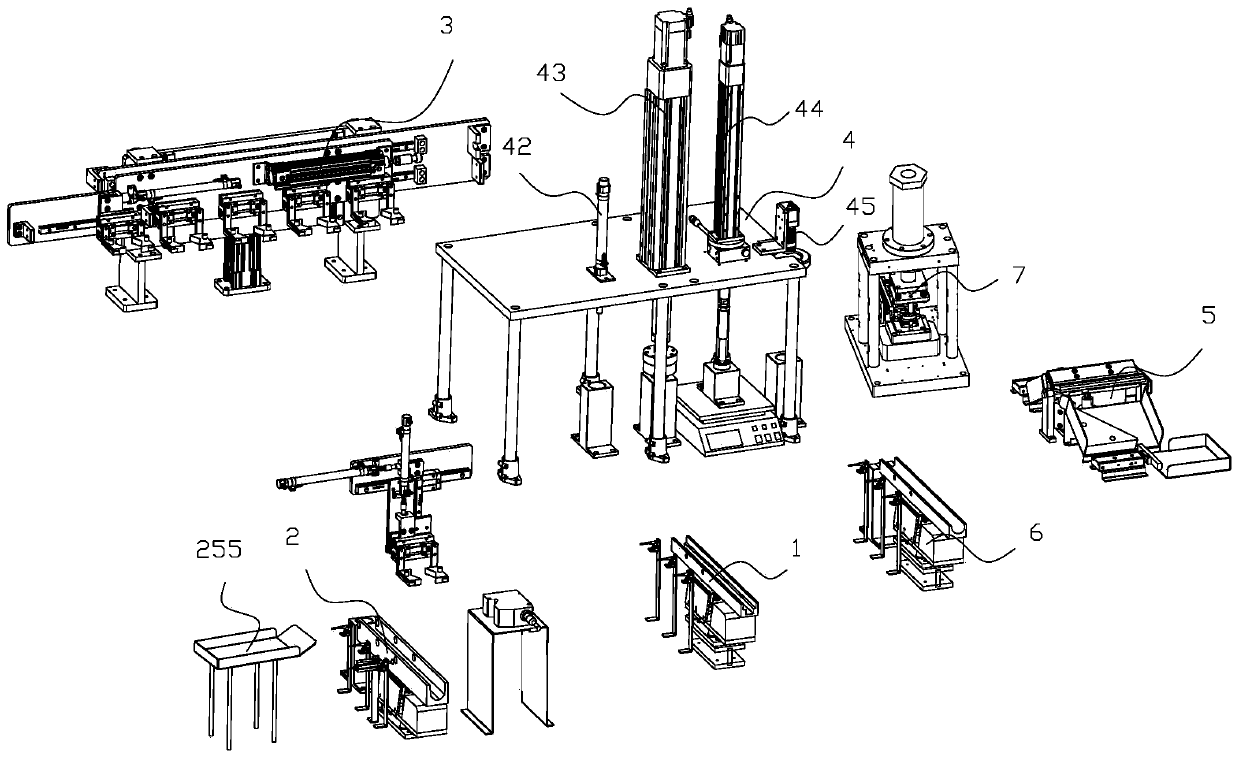

Spherical shell feeding detection device and method for universal spherical joint production

The invention relates to the technical field of universal spherical joint production, in particular to a spherical shell feeding detection device for universal spherical joint production. The spherical shell feeding detection device comprises a spherical shell linear conveyor, a locating air cylinder, a spherical shell detector, a spherical shell connecting containing frame and a detection and clamping assembly. Locating holes are formed in the left portion of the spherical shell linear conveyor. The locating air cylinder is located on the left side of the spherical shell linear conveyor through a locating and detection supporting frame. A locating pin is arranged on the moving portion of the locating air cylinder and is matched with the locating holes. The spherical shell detector is arranged on a rack through a detection support and is located above the spherical shell linear conveyor and used for visually detecting spherical shell quality. The detection and clamping assembly is usedfor clamping and transferring unqualified spherical shells. The spherical shell connecting containing frame is connected to the rear end of the spherical shell linear conveyor. The spherical shell feeding detection device has the advantages that the product quality of fed spherical shells is improved, and the assembly quality of spherical shells and spherical heads is improved.

Owner:高鑫斌

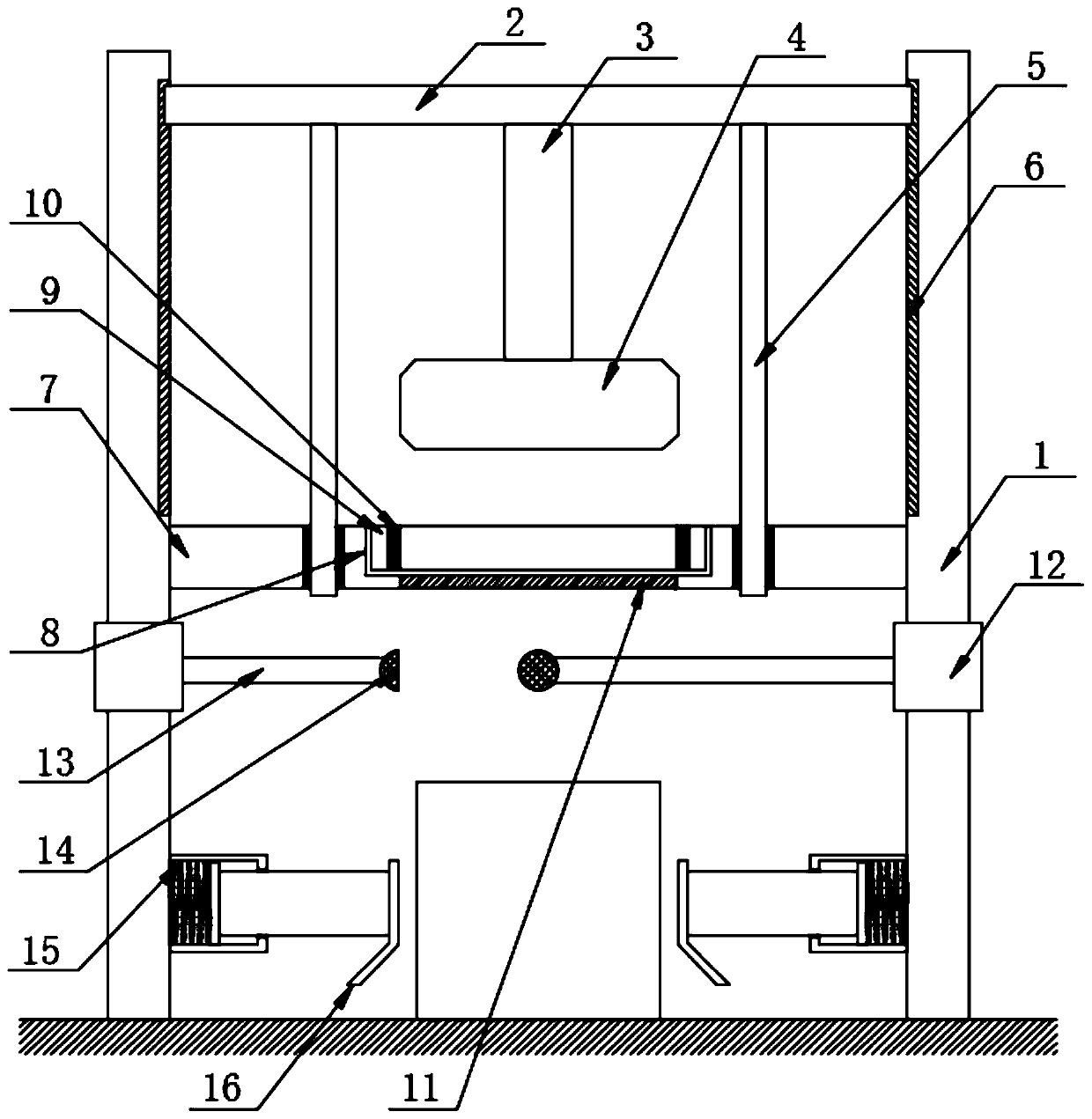

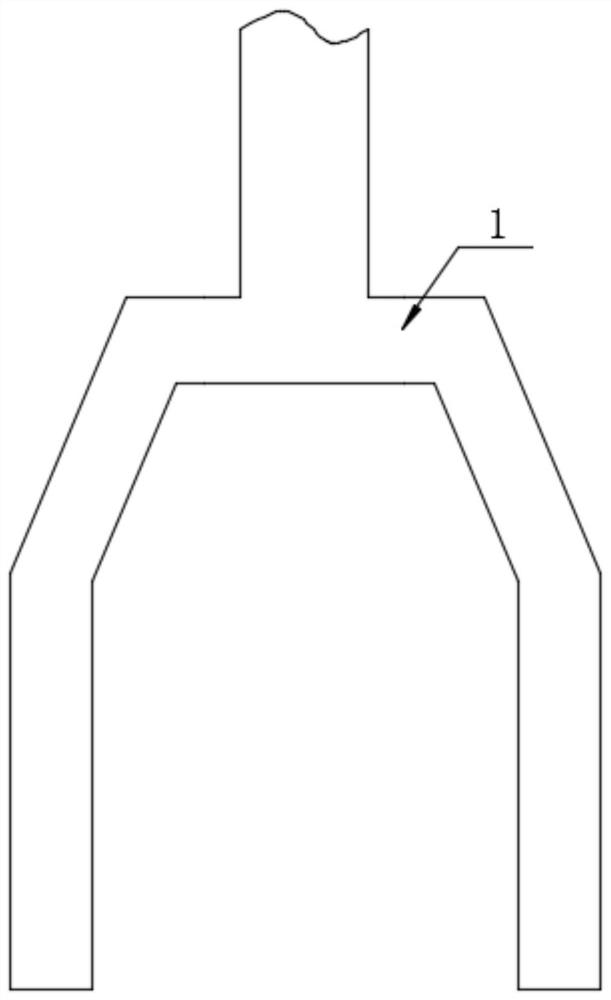

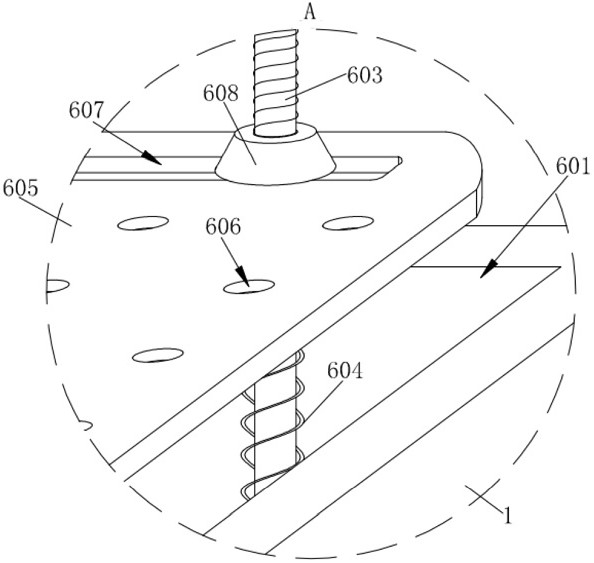

Household decoration pipeline sealing device convenient for subsequent clearing

ActiveCN111503415AReduce frictional resistanceShorten the timePipe elementsCleaning processes and apparatusEngineeringStructural engineering

The invention discloses a household decoration pipeline sealing device convenient for subsequent clearing, and particularly relates to the field of household decoration auxiliary devices. The device comprises two supports which are vertically and symmetrically arranged, the supports are of inverted Y-shaped structures, a pushing mechanism is arranged between the top ends of the two supports, the pushing mechanism comprises a transverse plate, a pushing rod is fixedly connected to the center of the bottom of the transverse plate, and a sponge block is fixedly arranged at the bottom end of the pushing rod. According to the device, by means of linkage between the pushing mechanism and a lubricating mechanism, in the downward moving process of the sponge wiping block, the pushing mechanism drives the lubricating mechanism to rotate to perform lubricating wiping on the sponge wiping block passing through the lubricating mechanism; and meanwhile, through linkage between a clearing mechanismand the pushing mechanism, when the pushing mechanism is pushed downwards, the clearing mechanism does not operate, and when the pushing mechanism is pulled upwards, the pushing mechanism drives the clearing structure to operate to beat the sponge block to clear building chippings attached to the top of the sponge block.

Owner:广州珠江建筑装饰有限公司

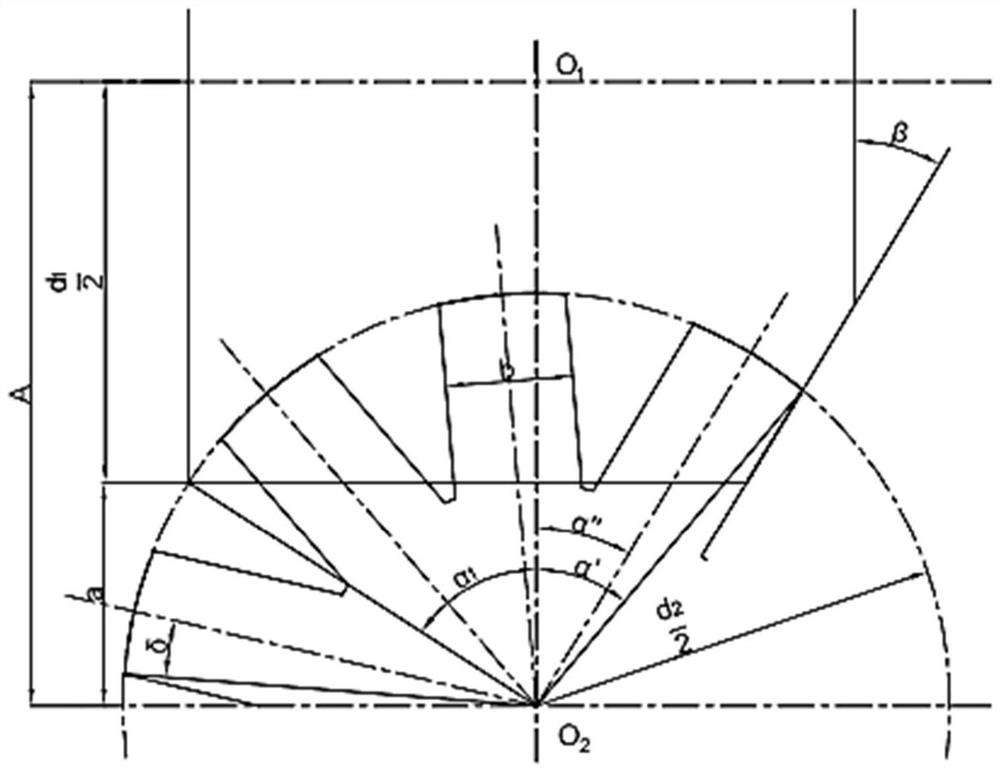

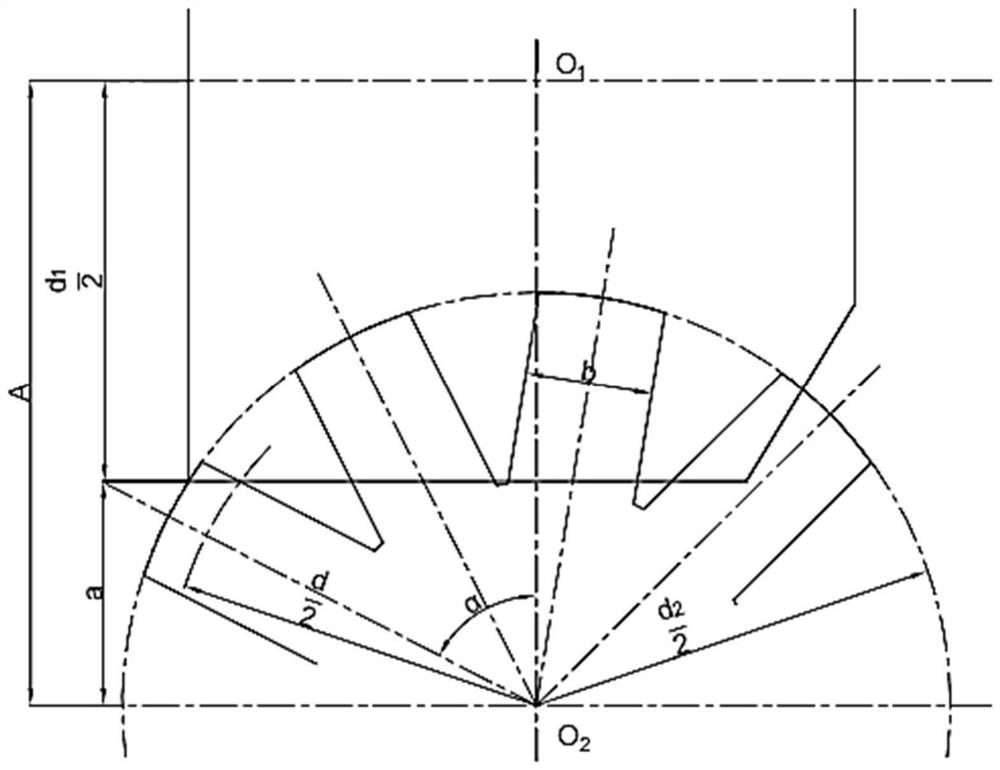

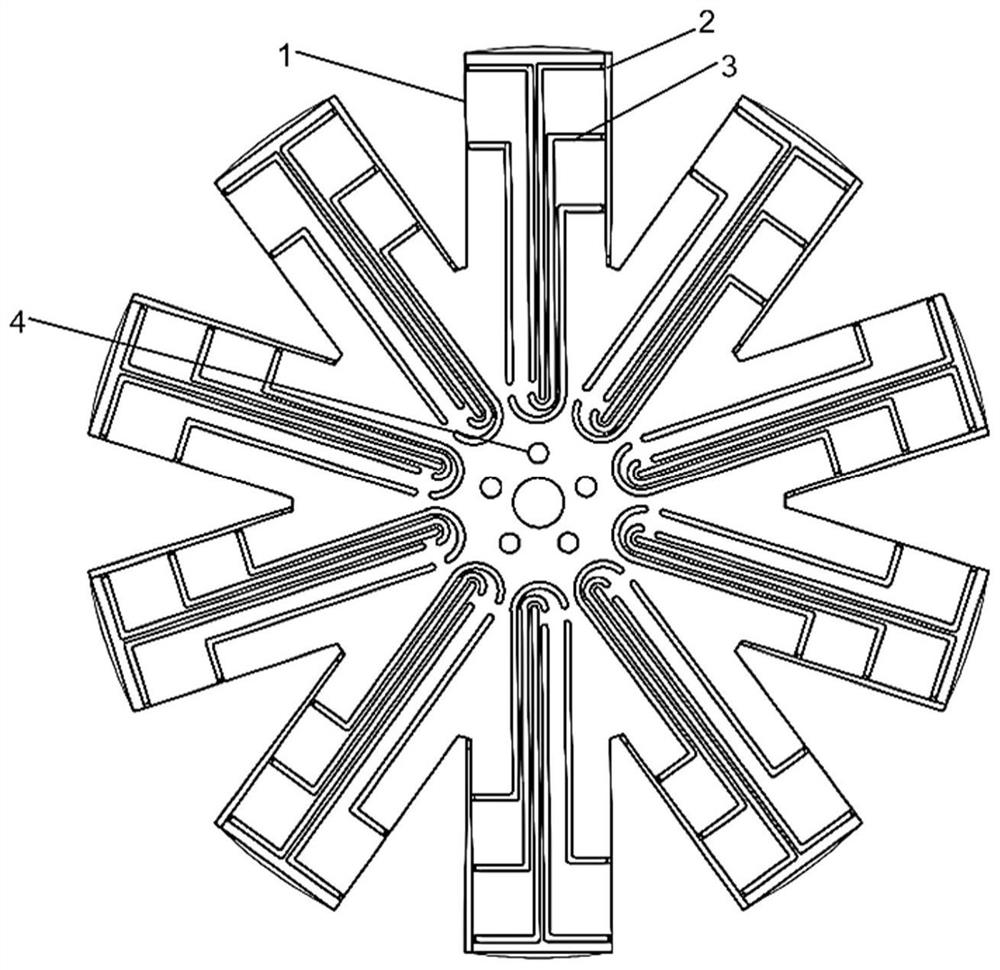

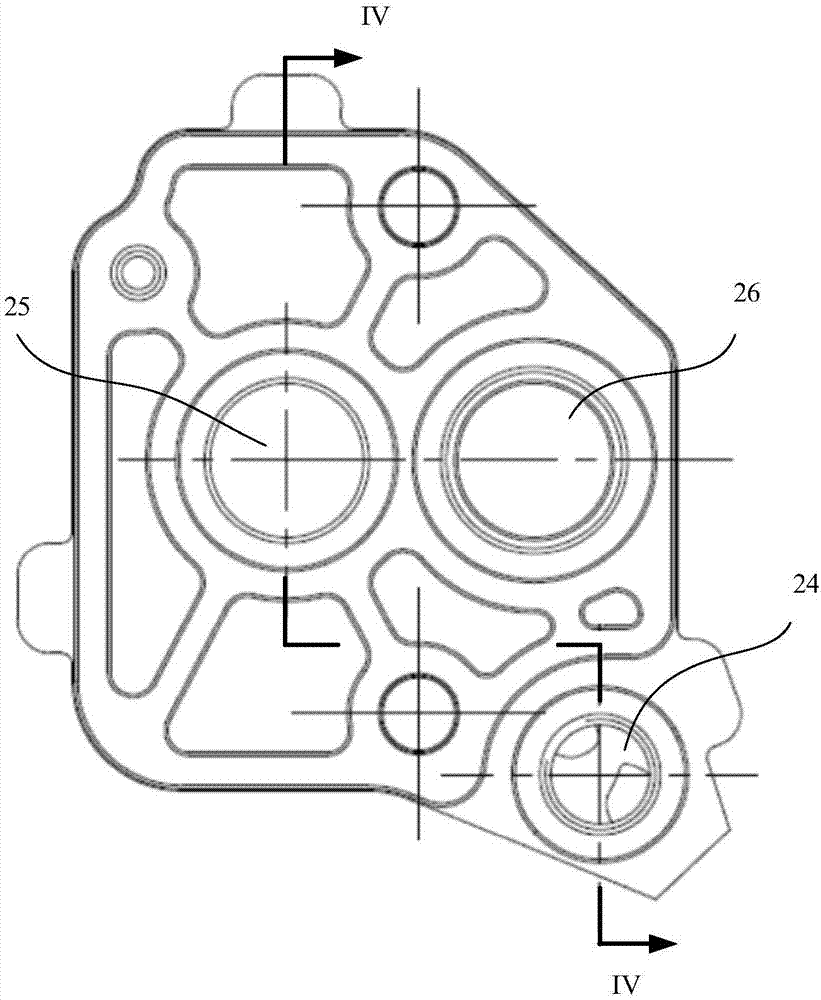

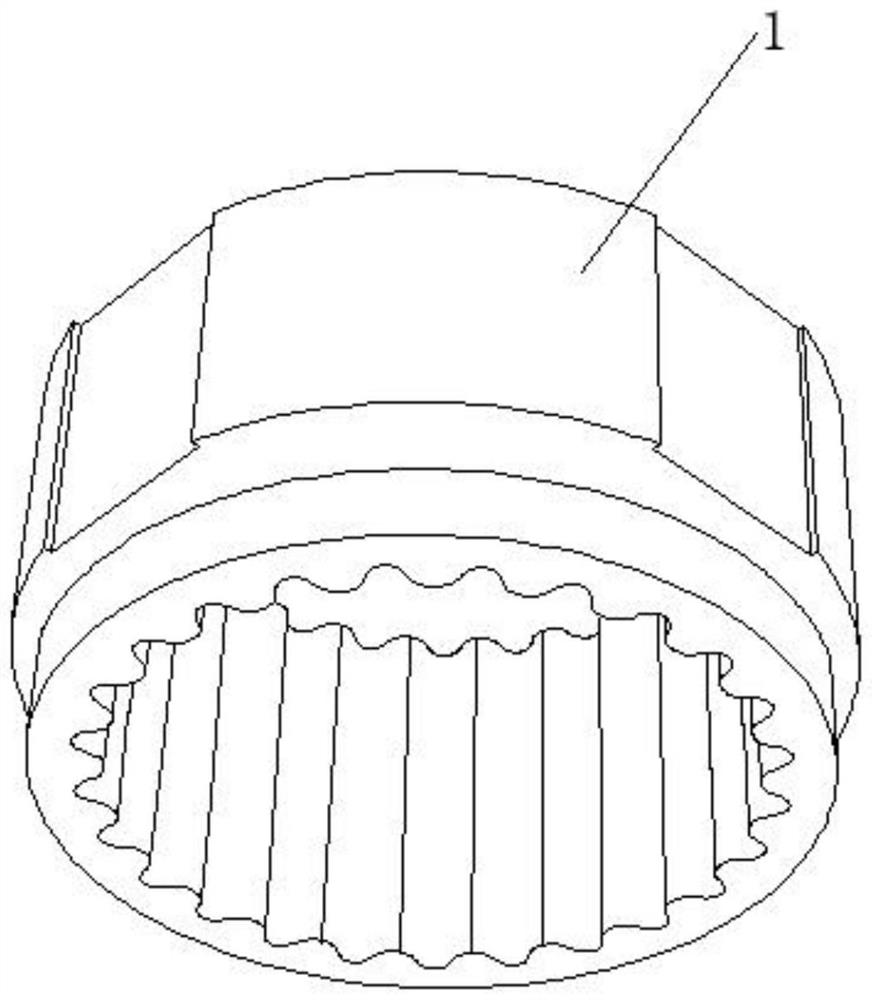

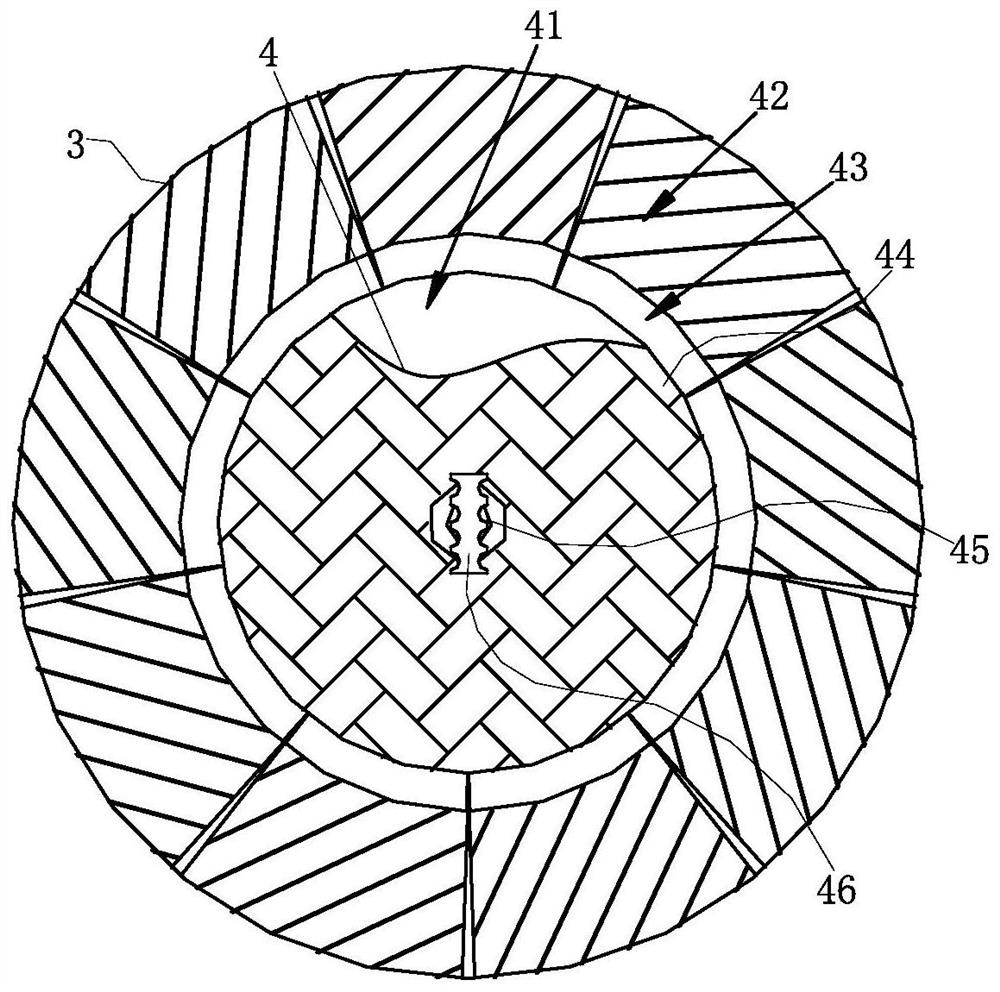

Single-screw compressor star wheel-screw meshing pair liquid spraying lubrication structure and design method

ActiveCN114658653AReduce wearPrecision lubricationRotary piston pumpsRotary piston liquid enginesEngineeringLubrication

According to the single-screw compressor star wheel-screw meshing pair liquid spraying lubrication structure and the design method, the liquid spraying lubrication structure comprises a star wheel body internally provided with a plurality of channels, outlets corresponding to all the channels are formed in different positions of the side faces of star wheel teeth, cooling liquid is led into the channels from inlets corresponding to all the channels, then drainage is conducted through the channels, and therefore the liquid spraying lubrication effect is achieved. And finally, the oil is sprayed into the star wheel-screw rod meshing pair from an outlet corresponding to each channel, so that precise lubrication of the star wheel-screw rod meshing pair is realized. The design method comprises the following steps: calculating a star wheel rotation angle range when the star wheel is engaged with the screw rod, so that the size of the liquid supply port corresponds to the star wheel rotation angle range. And when the inlets communicate with the liquid supply ports, cooling liquid is introduced into the channels from the inlets corresponding to the channels, and when the inlets leave the liquid supply port area, liquid supply of the corresponding channels is finished. Precise lubrication between the tooth side of the meshing pair star wheel and the tooth groove of the screw can be achieved, and excessive liquid spraying on the star wheel teeth not in the meshing range is avoided.

Owner:XI AN JIAOTONG UNIV

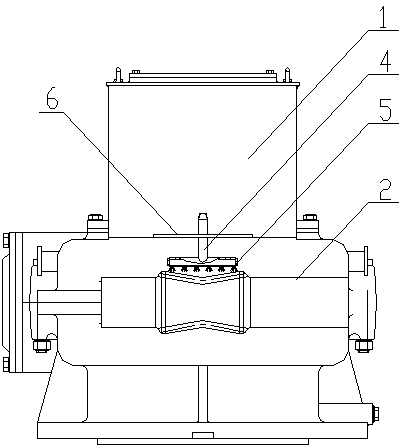

Speed reducer lubricated through fuel injection pipe

The invention relates to a speed reducer lubricated through a fuel injection pipe. The speed reducer comprises a casing, wherein a worm and gear mechanism is arranged in the casing; the fuel injection pipe is arranged above a position where a worm gear is meshed with a worm; the fuel injection pipe is T-shaped; a plurality of small holes are formed in the cross section of the fuel injection pipe; the cross section of the fuel injection pipe is correspondingly arranged right above the meshing sections of the worm gear and the worm; one end of the vertical section of the fuel injection pipe extends out from a sight hole cover of the casing. The speed reducer lubricates gears through the T-shaped fuel injection pipe, the cross section of the T-shaped fuel injection pipe completely covers the meshing sections of the two gears, the fuel injection pipe always supplies lubricating oil to the meshing sections and cools the meshing sections during meshing operation of the gears, and the gears are more completely lubricated.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

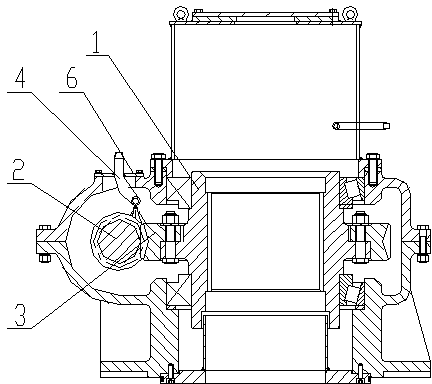

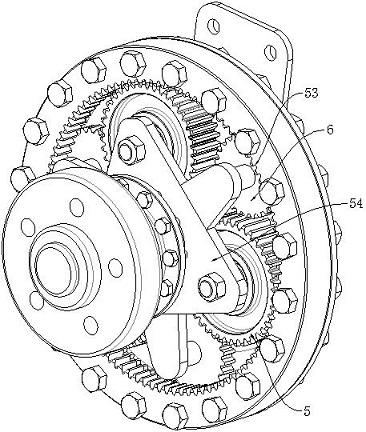

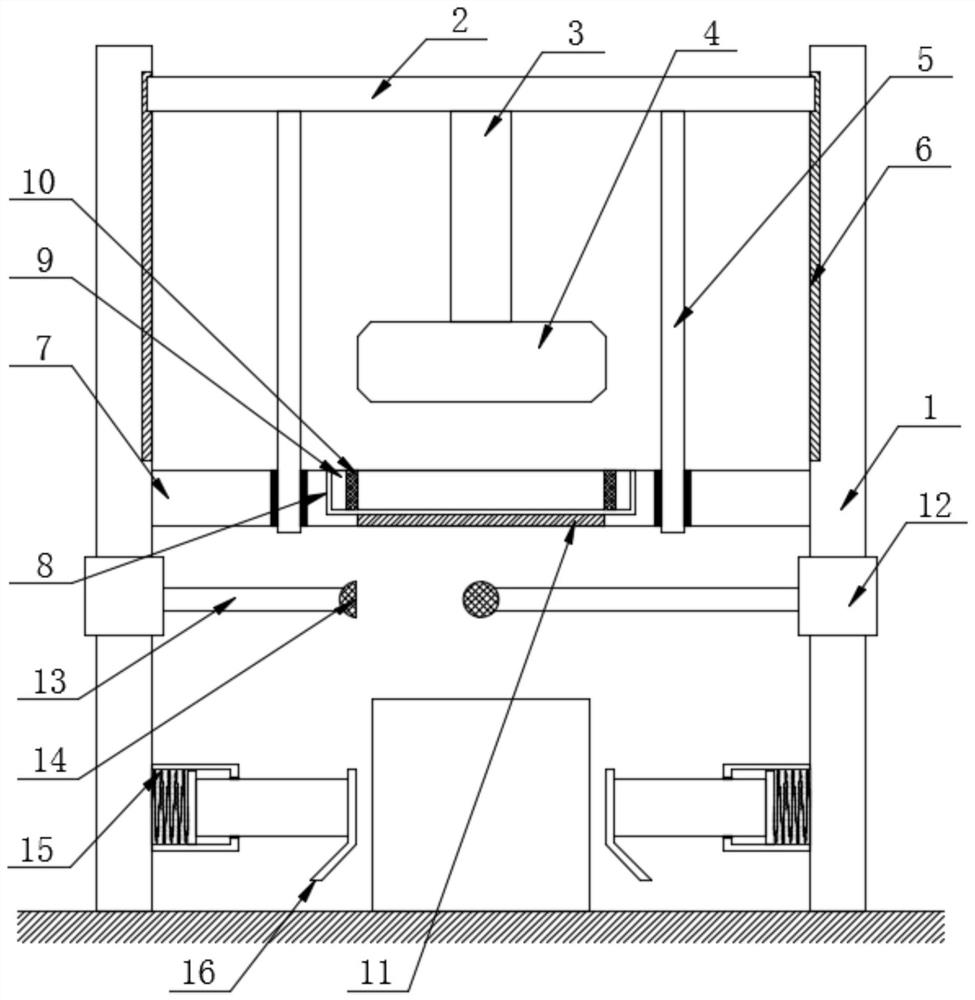

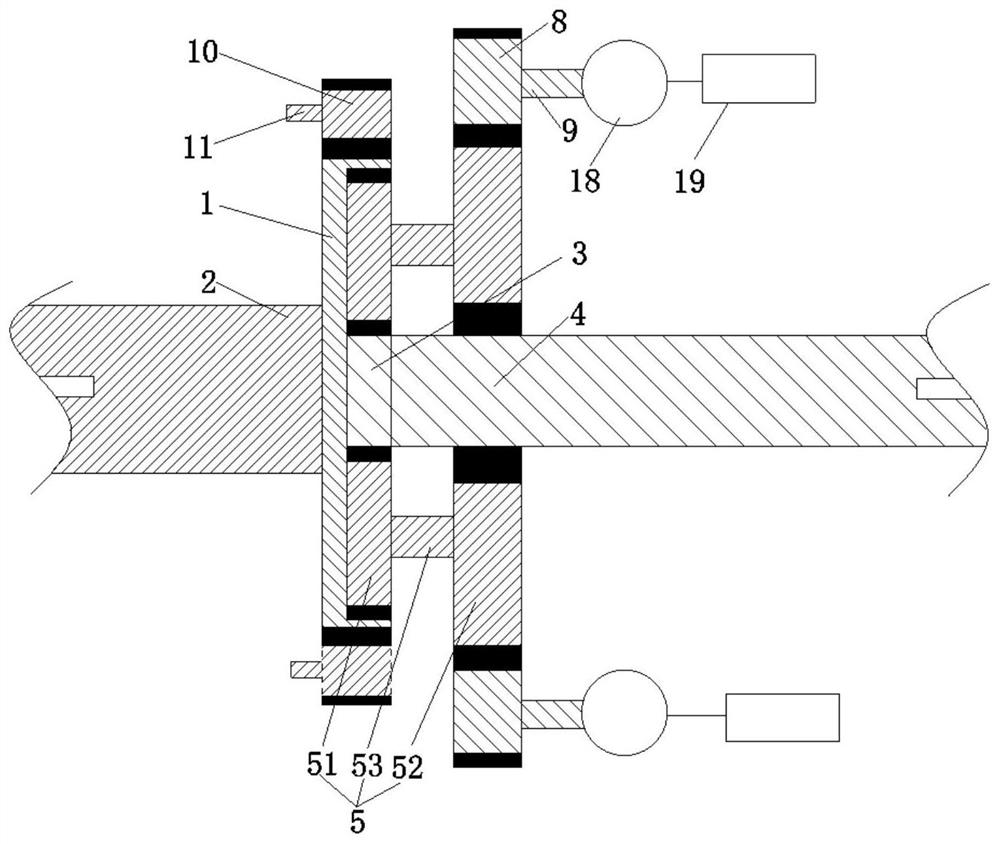

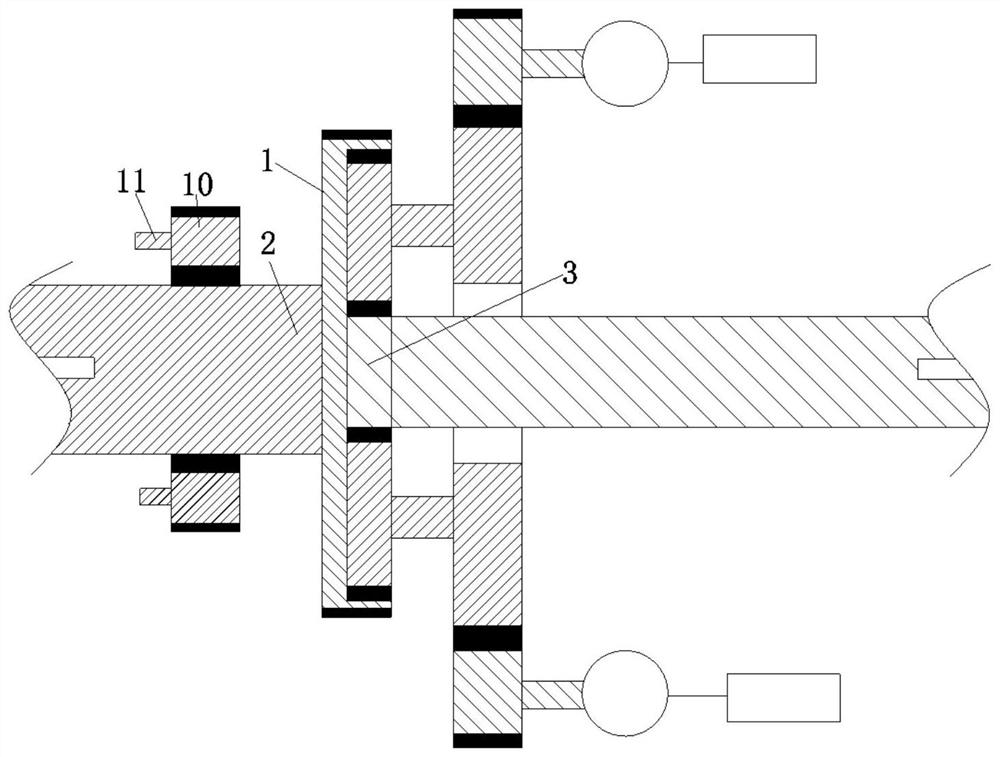

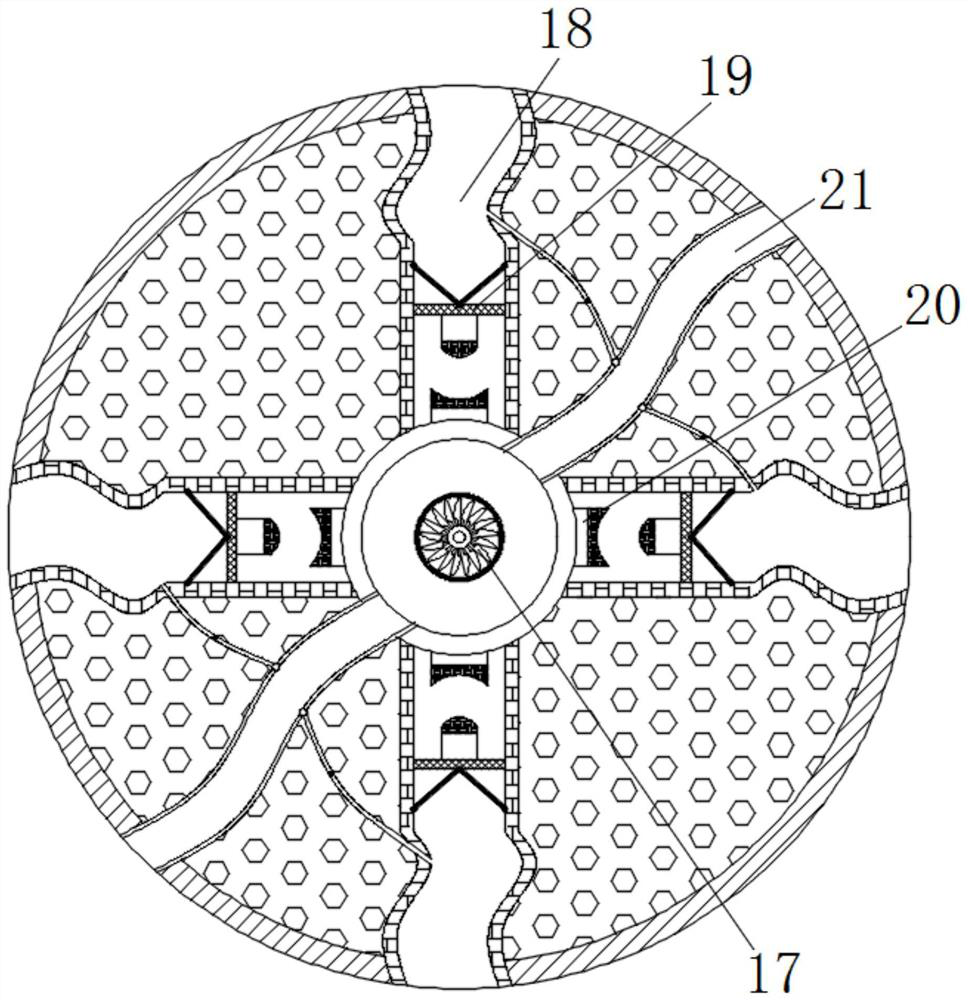

Gear box of wheel edge driving system of new energy automobile

InactiveCN113775705AComprehensive lubricationExtended service lifeGearboxesGear lubrication/coolingOil canNew energy

The invention discloses a gear box of a wheel edge driving system of a new energy automobile. The gear box comprises a shell, an input shaft, an output shaft and a transmission mechanism; a mounting plate is arranged on one side of the shell, the mounting plate is mounted on an automobile body, and lubricating oil can be added into the shell; the input shaft is connected with an automobile motor, and the input shaft is inserted into the shell and is rotationally connected with the shell; a wheel disc is arranged at the end of the output shaft, multiple mounting holes are formed in the wheel disc, the wheel disc is connected with an automobile hub through mounting holes and bolts, and one end of the output shaft is inserted into the shell and rotationally connected with the shell; and the transmission mechanism is mounted in the shell, and the transmission mechanism is connected with the output shaft and the input shaft. According to the gear box, lubricating oil can be pushed in the reverse direction of revolution of a planetary gears, then the lubricating oil can lubricate the planetary gear and an inner gear more comprehensively, more gears are lubricated by oil, and the service life of the gear box is prolonged.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

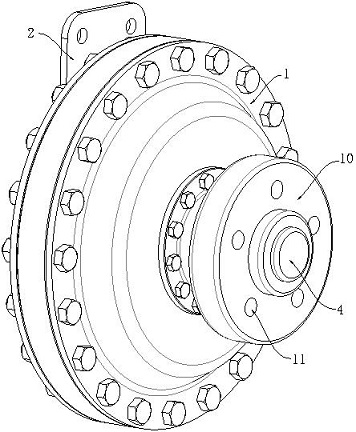

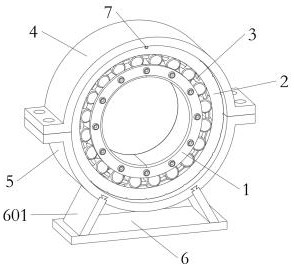

Conveniently-fixed self-aligning roller bearing for roller of belt conveyor

ActiveCN114576265AEasy to addEasy accessRolling contact bearingsRollersStructural engineeringMechanics

The invention provides a self-aligning roller bearing convenient to fix for a belt conveyor roller, relates to the technical field of self-aligning roller bearings, and solves the problems that lubricating oil is inconvenient to add into a roller bearing, and the lubricating oil is easy to throw out from an oil guide pipe after oil injection. The self-aligning roller bearing convenient to fix for the belt conveyor roller comprises a bearing inner ring, two sets of arc-shaped grooves are symmetrically formed in the outer end face of the bearing inner ring, friction blocks and the bearing outer ring are evenly installed on the inner end face and the outer end face of the bearing inner ring, a groove is formed in the middle of the outer end face of the bearing outer ring, the groove is of a T-shaped structure, and the bearing outer ring is connected to the outer portion of the bearing inner ring in a sleeving mode. According to the bearing, the reset spring is installed at the rear end of the sliding block, after oil injection is finished, the plug plate at the outer end of the sliding block plugs the through hole in the middle of the fixed block under the elastic force effect of the reset spring, and the situation that lubricating oil in the bearing is thrown to the outside through the oil guide pipe when the bearing runs is prevented.

Owner:山东华工轴承有限公司

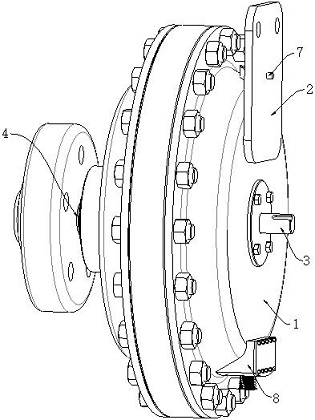

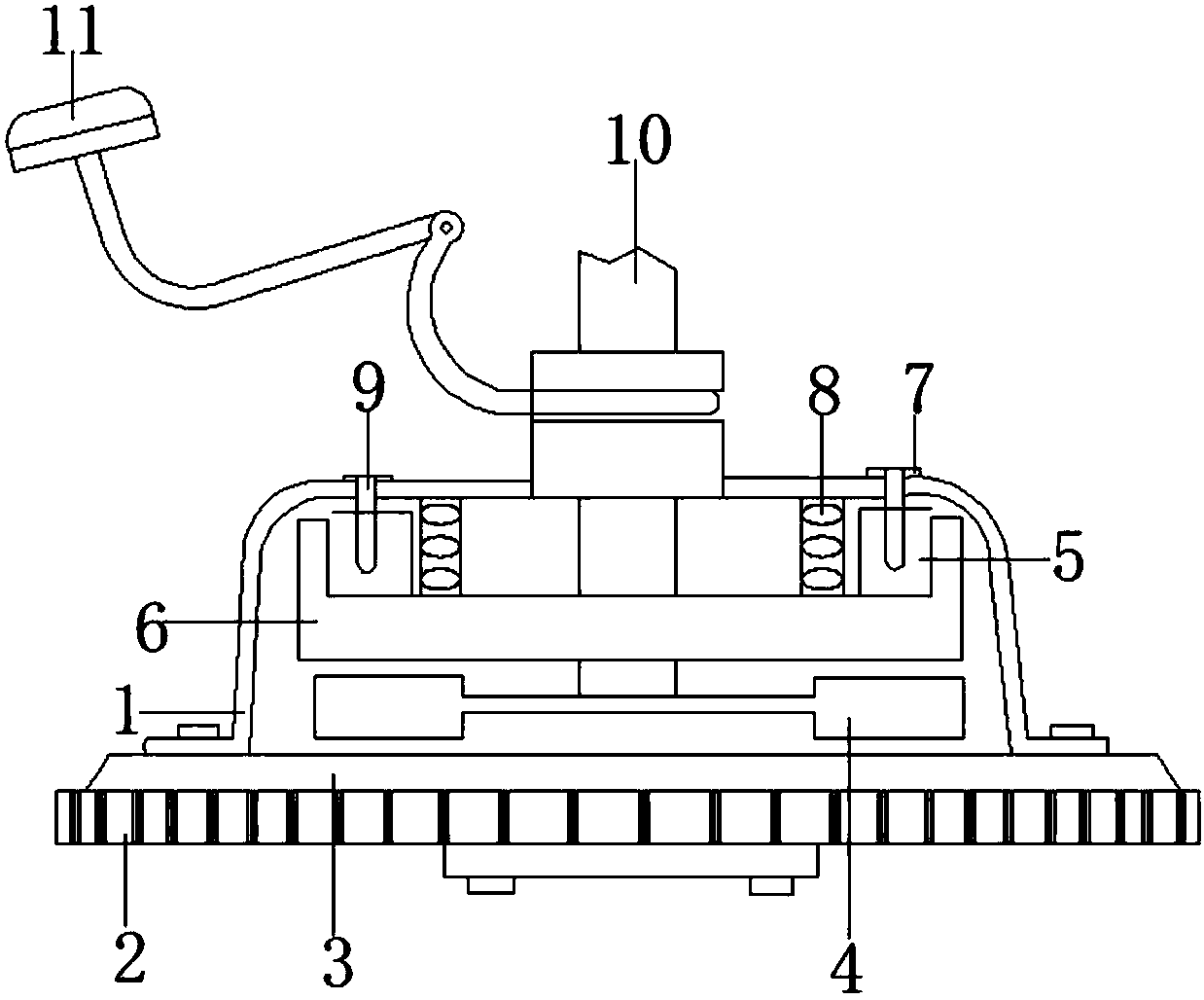

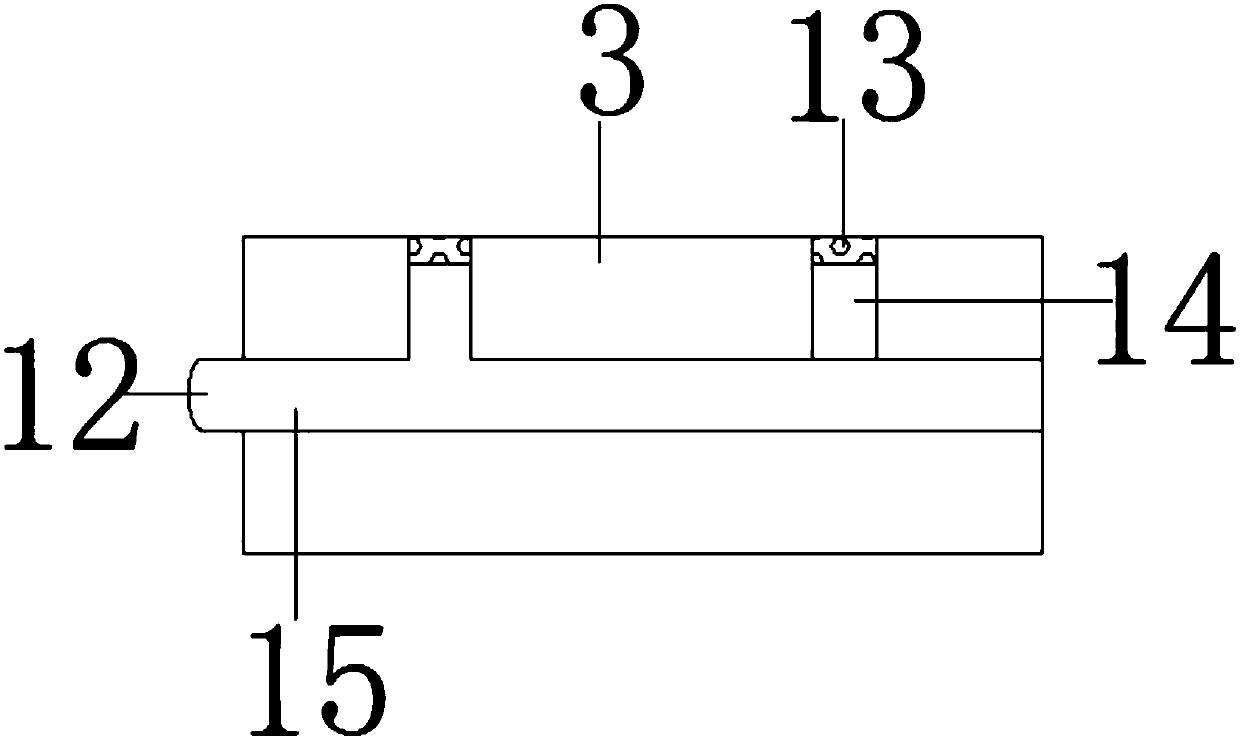

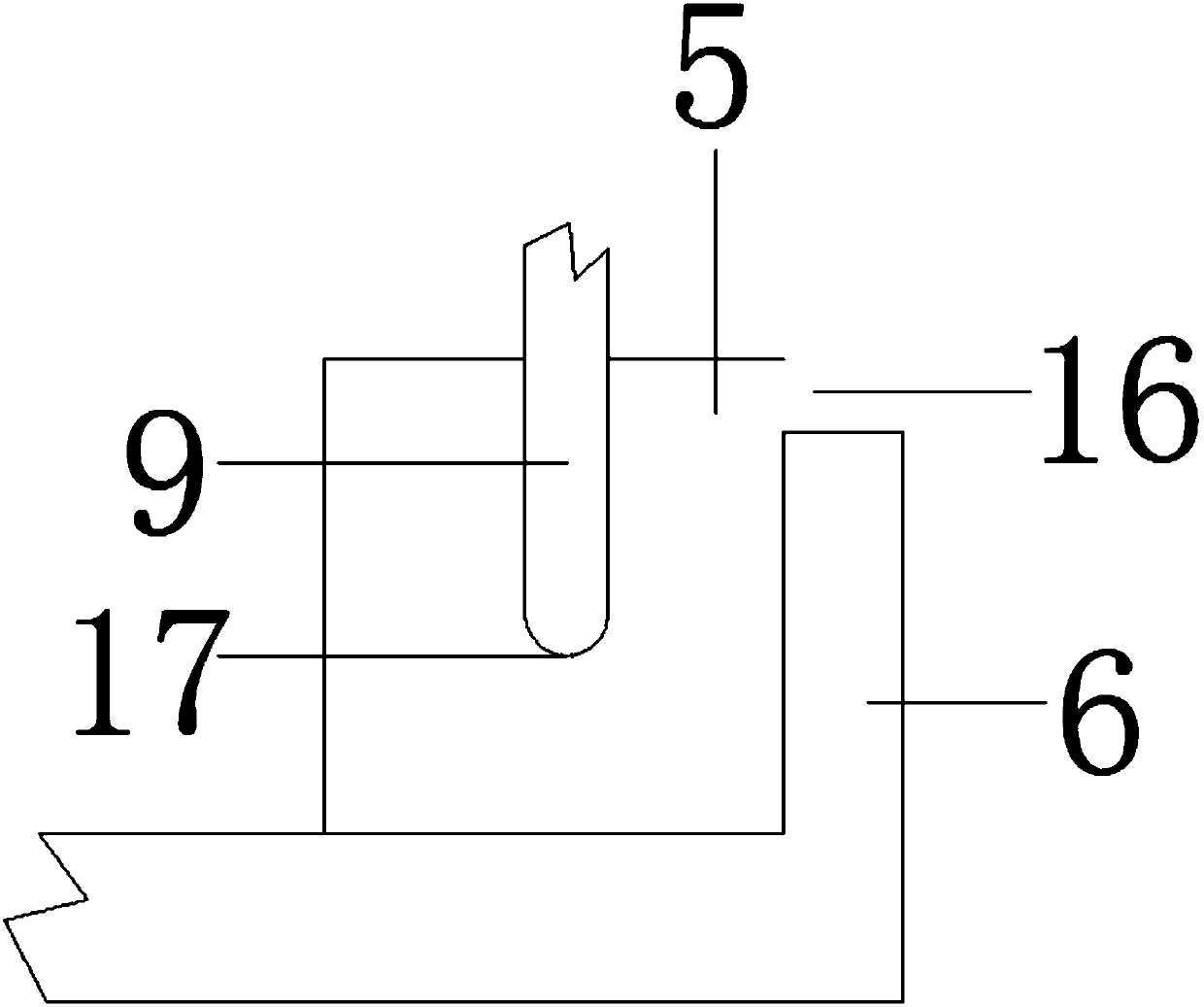

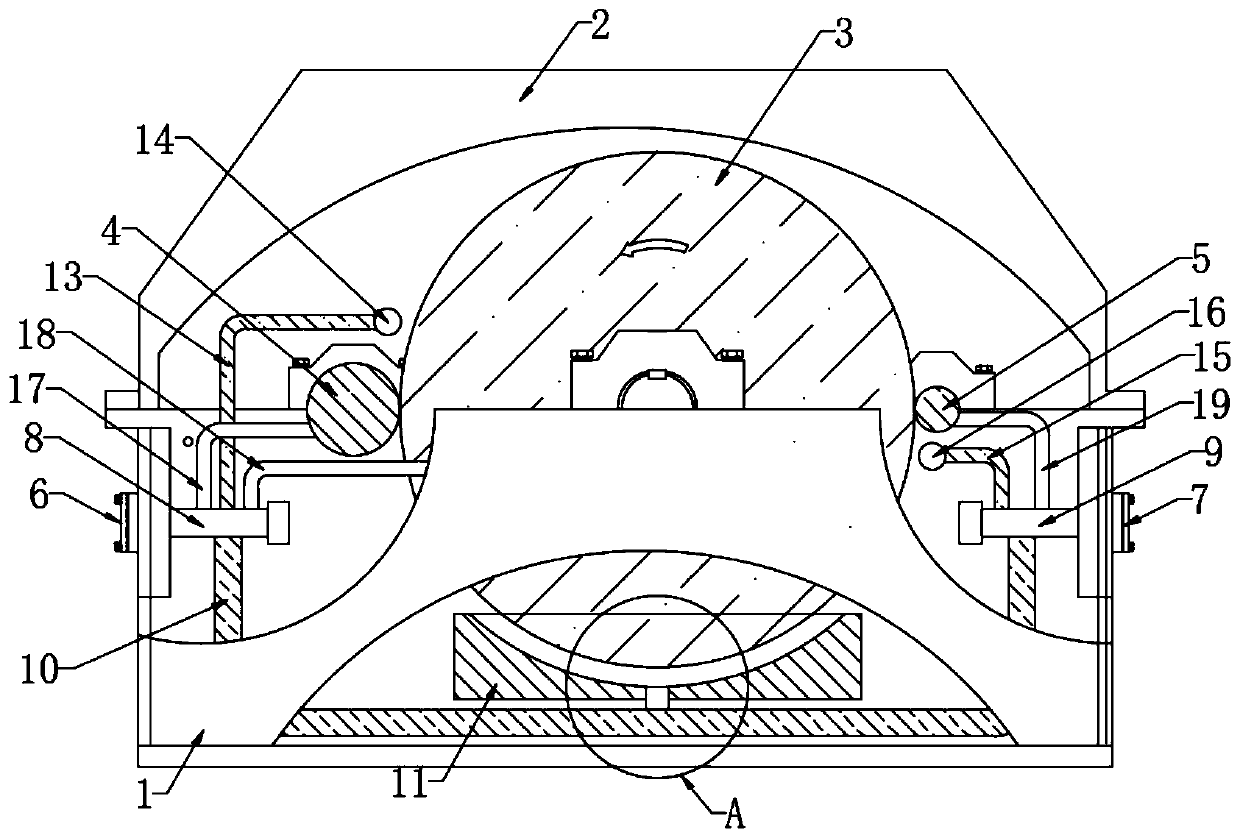

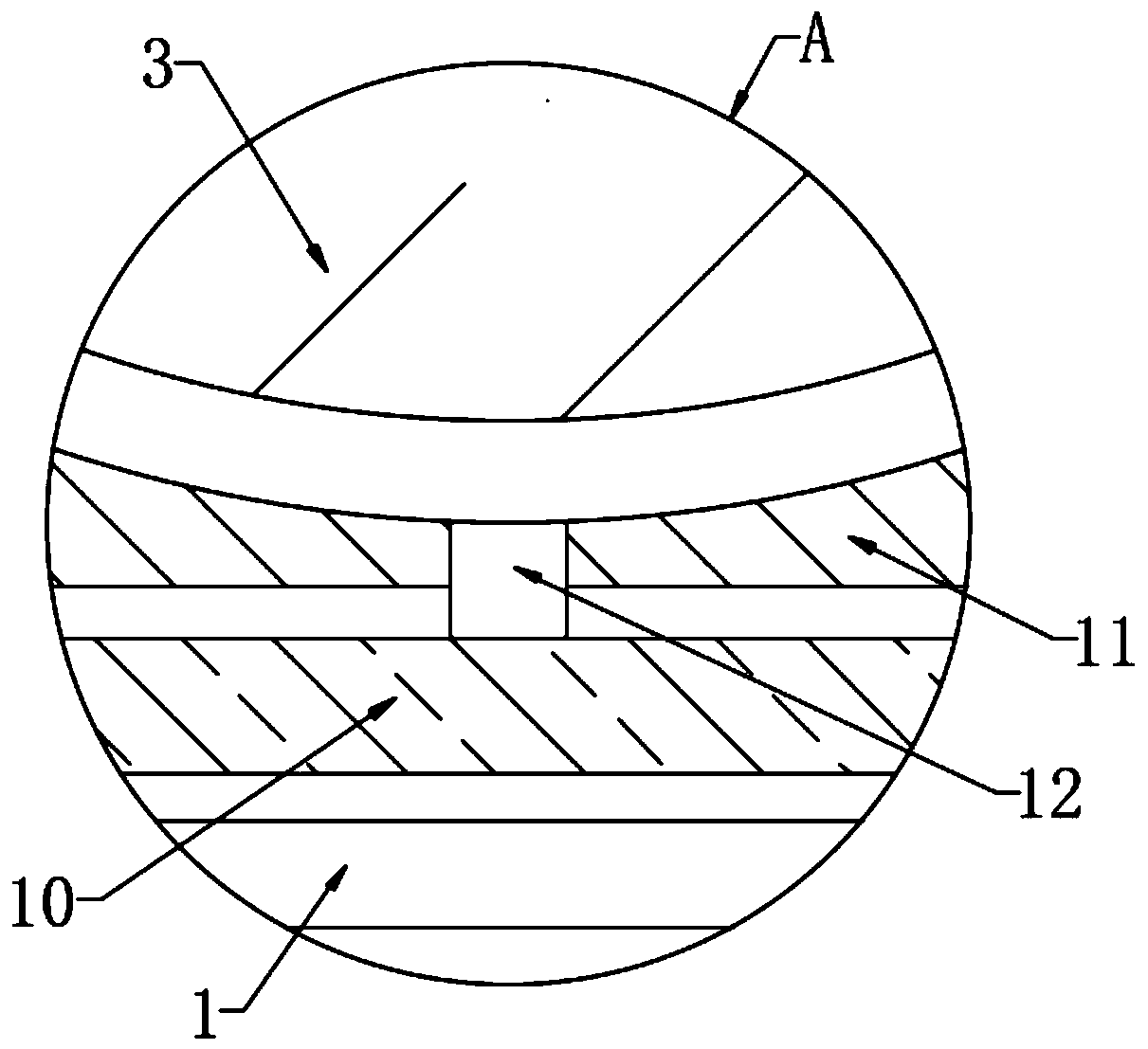

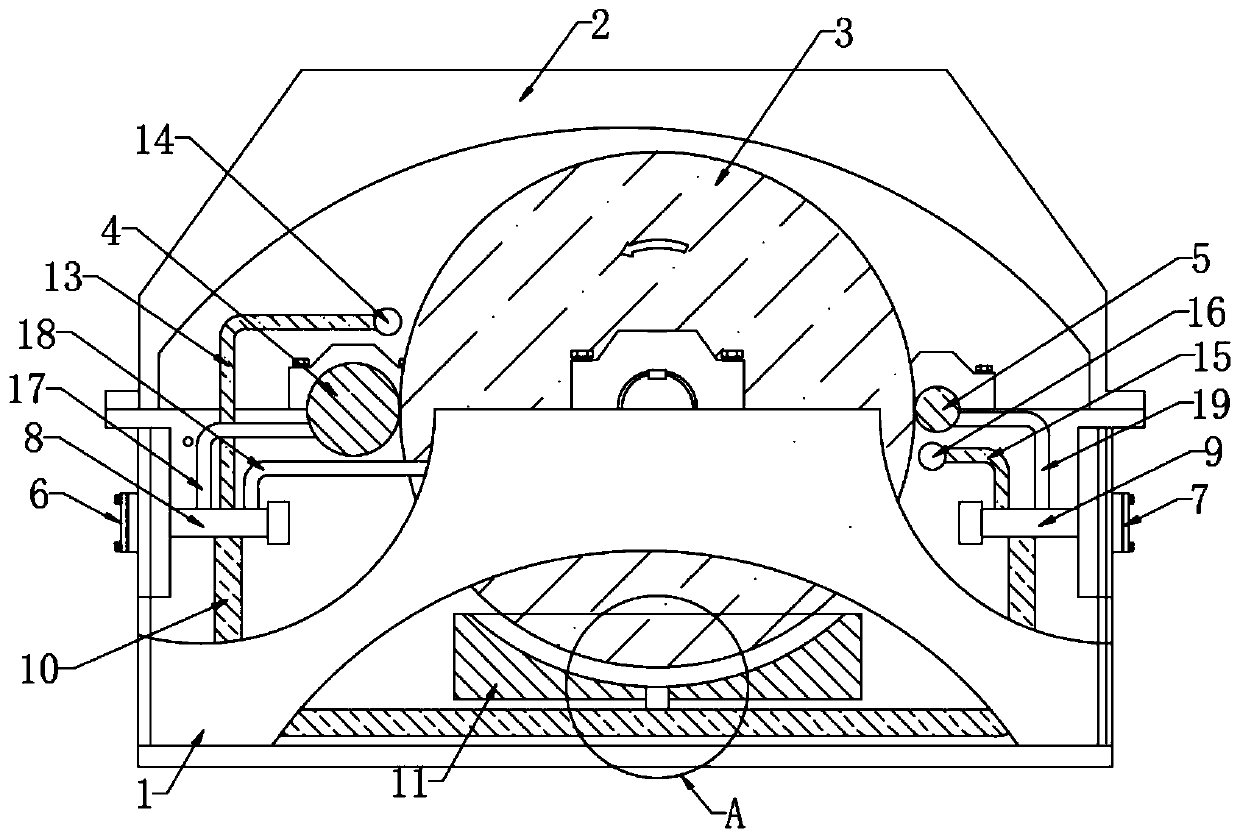

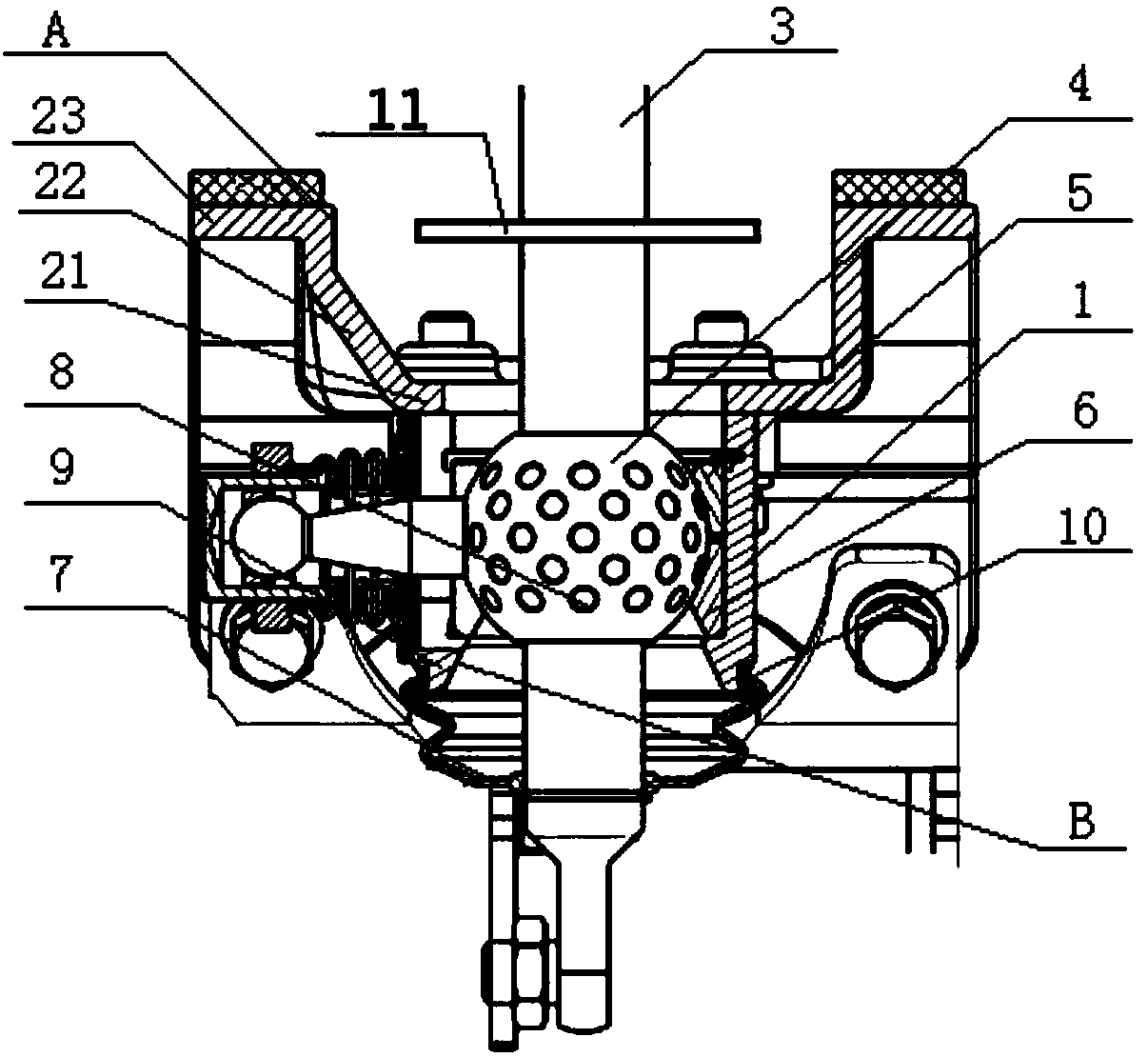

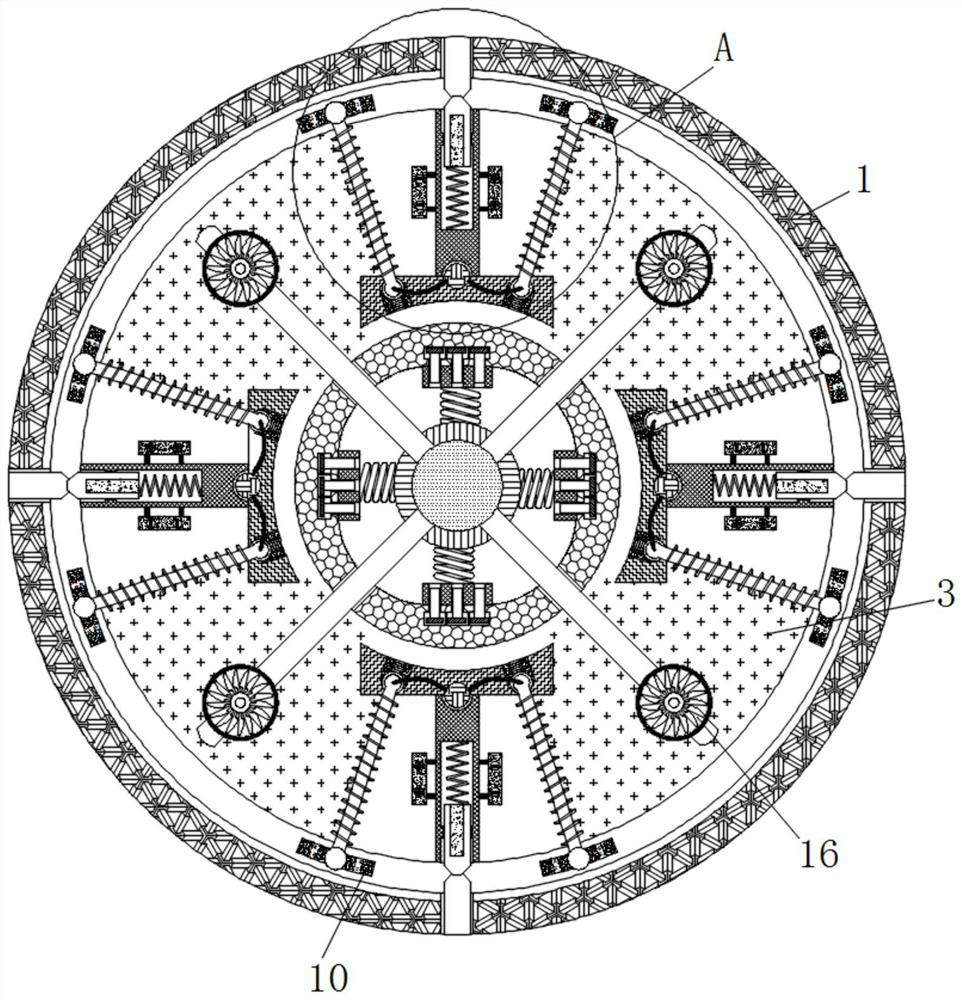

Lubricating structure for motorcycle clutch

InactiveCN107763100AGuaranteed real-time lubricationEnsure comprehensivenessFriction clutchesClutchLubrication

The invention discloses a lubricating structure for a motorcycle clutch, which comprises an outer cover, a gearbox input shaft and a clutch pedal. A gearbox input shaft is arranged in the middle of the outer cover, and a clutch pedal is arranged on the outer side of the outer cover, and the clutch pedal is socketed. At one end of the input shaft of the gearbox, a pressure plate is provided inside the outer cover, and the pressure plate is connected to the top of the outer cover through a spring. An oil tank is arranged on both sides of the upper part of the pressure plate, and a pressure rod is arranged inside the oil tank. The top of the pressure rod is connected to a threaded cap and threaded The cap is located on the surface of the outer cover, and the bottom of the pressure rod is provided with a drip port. The present invention can increase the lubricating oil inside the clutch, which is convenient for replenishing the lubricating oil inside the clutch in time, and can fully lubricate the inside of the clutch, ensuring the comprehensiveness of the clutch lubrication, and can pass the excess lubricating oil through the clutch after lubricating the clutch. The filter screen is collected in the central tube, which is convenient for the secondary use of the lubricating oil, and can also overflow the lubricating oil, causing inconvenience to use.

Owner:WUXI CHUANGGE TECH CO LTD

Hinges for hinge blowout preventer

PendingCN105201442ASmall closing resistanceReasonable structureSealing/packingEngineeringBlowout preventer

The invention discloses hinges for a hinge blowout preventer. Each hinge is formed by connecting a cuboid section with a cylindrical section, wherein a hydraulic oil opening inlet, a hydraulic oil closing inlet, a first channel communicated with the hydraulic oil opening inlet and a second channel communicated with the hydraulic oil closing inlet are formed in the cuboid section of each hinge; a hinge shaft hole is formed in the center of the cylindrical section of each hinge; the end of each first channel and the end of the corresponding second channel are communicated with the corresponding hinge shaft hole; a lubrication oil through hole is formed in one side of each hinge shaft hole, and the hinge shaft hole and the corresponding lubrication oil through hole penetrate through the upper end surface and the lower end surface of the corresponding cylindrical section; annular grooves communicated with each lubrication oil through hole are formed in the upper end surface and the lower end surface of the corresponding cylindrical section. The hinges have the advantages that the structure is reasonable; machining and mounting are convenient; the opening and closing resistance of the hinges is small, and the hinges cannot rust after being used for a long time; with the adoption of the external lubrication oil channels, operation is convenient, comprehensive lubrication is realized, and opening and closing torque of a side door can be reduced. The hinges are universal, so that difference among oil circuits cannot be caused, a worker can perform mounting operation conveniently, and the mounting time is reduced.

Owner:JINHU FUYUAN MACHINERY

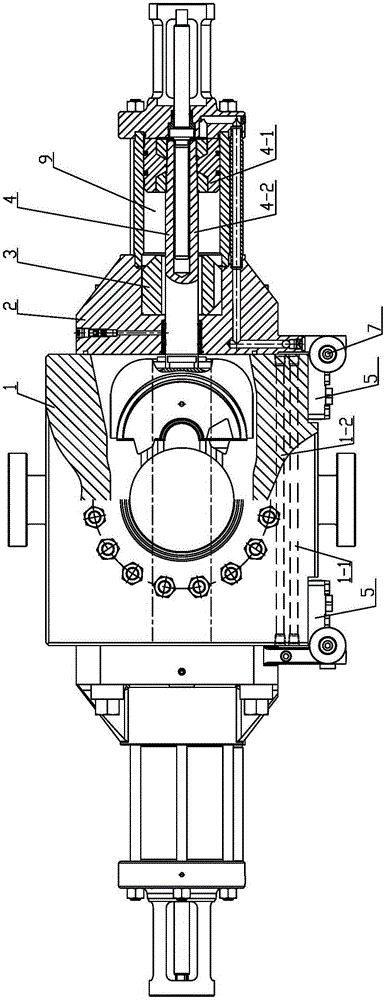

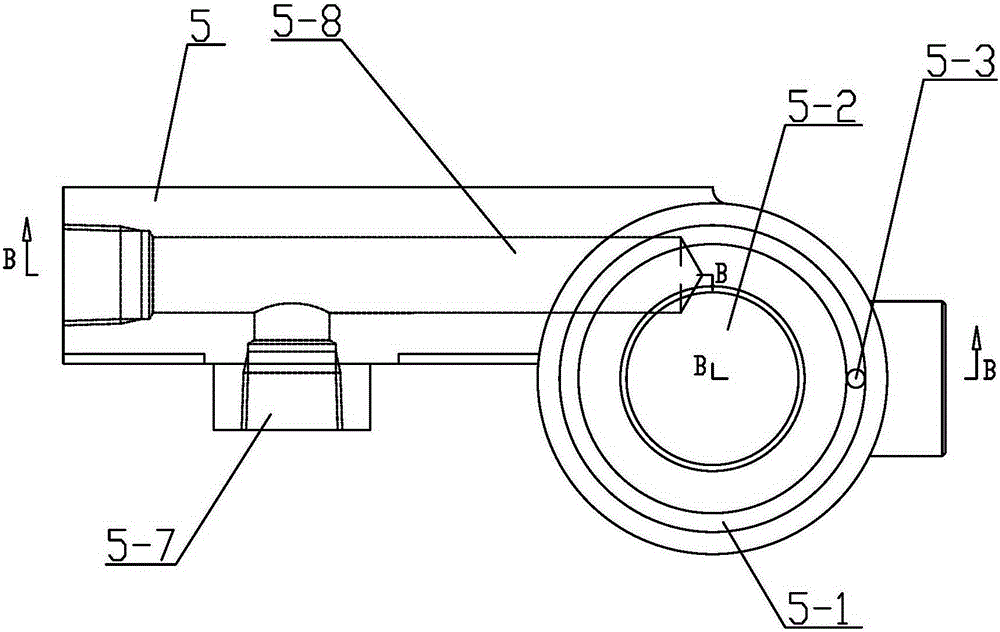

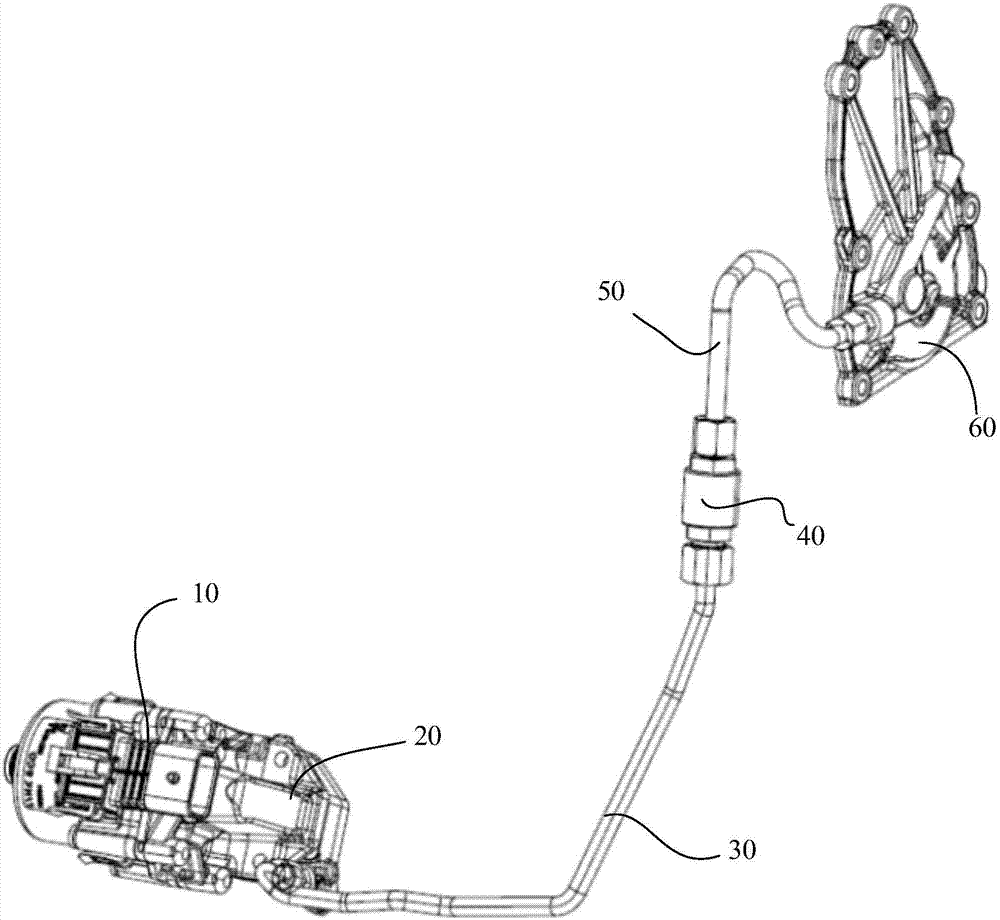

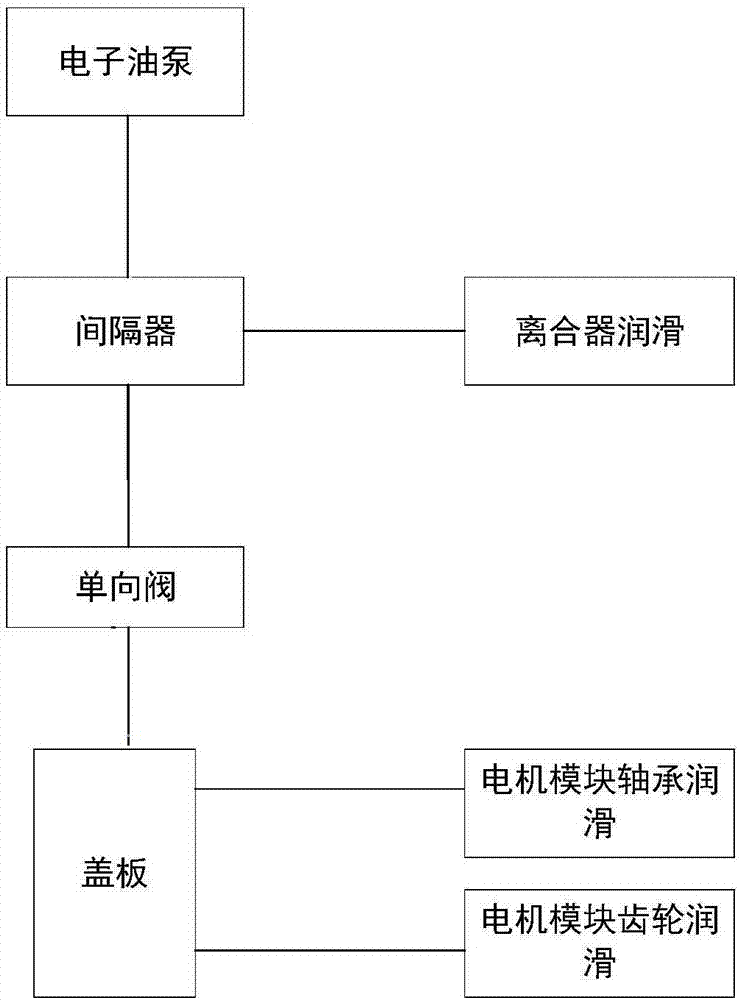

Driving lubrication structure of speed changer

ActiveCN107387738AReduce lubricationReduce cooling effectGear lubrication/coolingDistribution equipmentLubricationOil consumption

A driving lubrication structure of a speed changer comprises an electronic oil pump, a spacer, a first oil pipe, a one-way valve and a second oil pipe. The spacer is connected with the electronic oil pump and the first oil pipe. The one-way valve is connected between the first oil pipe and the second oil pipe. The spacer is internally provided with a first oil duct for conveying lubricating oil to the lower portion of the speed changer, and a second oil duct for conveying lubricating oil to the upper portion of the speed changer, and the lubricating oil entering the spacer passes through the electronic oil pump, then is injected back to the spacer and flows out through a first oil duct outlet of the first oil duct and a second oil duct outlet of the second oil duct. The first oil pipe is connected with the second oil duct outlet, and the second oil pipe leads to the upper portion of the speed changer. According to the driving lubrication structure of the speed changer, the lubricating oil is conveyed to a clutch on the lower portion of the speed changer and a motor module on the upper portion of the speed changer by additionally arranging the spacer and the one-way valve, oil consumption is reduced, and lubricating is really achieved as required.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION

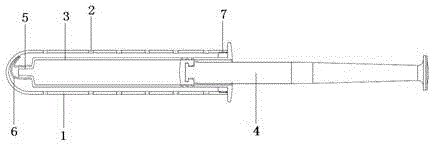

Disposable human body lubricator

The invention relates to a disposable human body lubricator and belongs to medical auxiliary products and adult hygiene products. The lubricator comprises a hollow inner pipe containing lubricating fluid, a lubricating outer pipe having lubricating effects and a piston push rod freely pushed in the hollow inner pipe. Fine holes are evenly distributed in the pipe wall of the hollow outer pipe of the lubricator. The disposable human body lubricator is low in cost and simple to operate, can comprehensively lubricate and expand the anus or the vagina, and is disposable and clean.

Owner:珠海张玉芝堂科技有限公司

Oil injection and splashing mixed lubrication system for integral-type high-speed gearbox

PendingCN109973635AComprehensive lubricationIncrease contact areaGear lubrication/coolingLubricationFuel tank

The invention discloses an oil injection and splashing mixed lubrication system for an integral-type high-speed gearbox. The oil injection and splashing mixed lubrication system comprises a box body and a box cover. The box body and the box cover are spliced together to form a complete lubrication box. A driving gear, a first driven gear and a second driven gear are arranged inside the box body. Arotating shaft of the driving gear is connected to side plates of the box body in a rotating mode through two first bearings. The rotating shaft of the driving gear is further externally connected with driving equipment. A rotating shaft of the first driven gear is connected to the side plates of the box body in a rotating mode through two second bearings. According to the scheme, the driving gear of the gearbox can drive the two driven gears to rotate at the same time, and transmission efficiency is greatly improved; meanwhile, meshing points between the gears can be fully lubricated; and acrescent-shaped oil receiving tank is arranged to be connected with a main oil inlet pipe inside the box, lubricating oil splashing down can be collected, the driving gear can be continuously subjected to immersed lubrication, contact area of the lubricating oil and the driving gear is increased and the lubricating effect is greatly improved.

Owner:南京创力传动机械有限公司

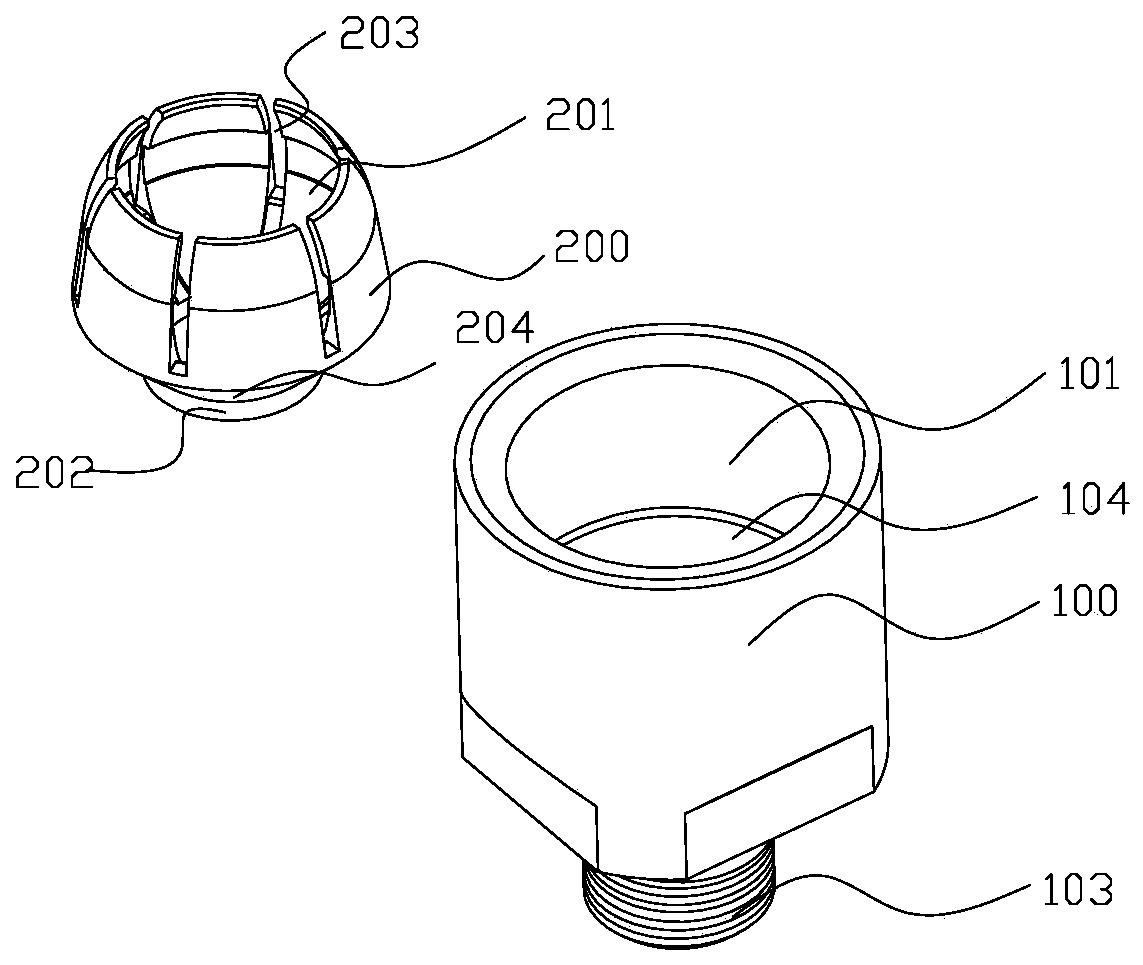

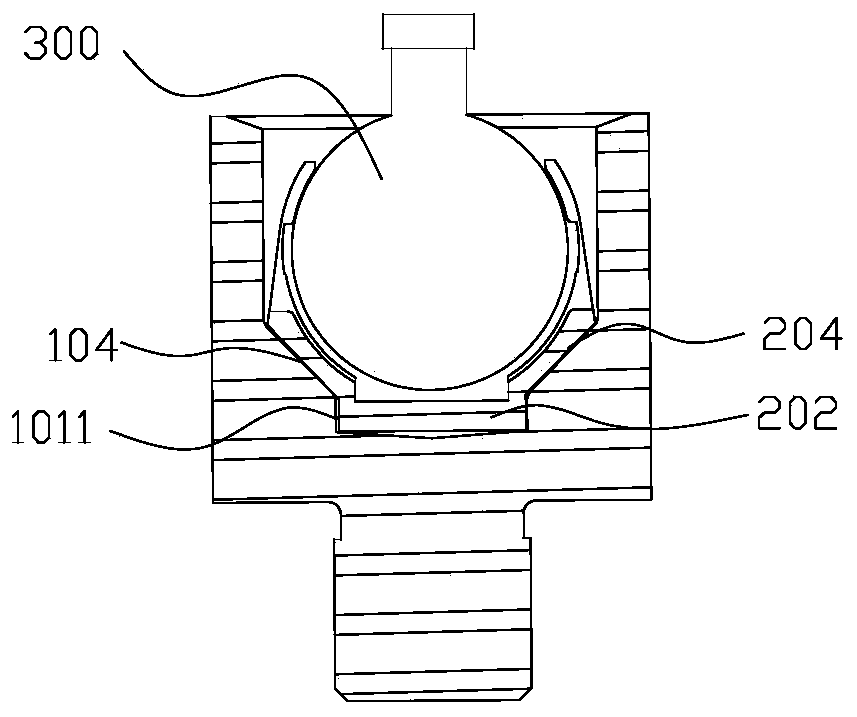

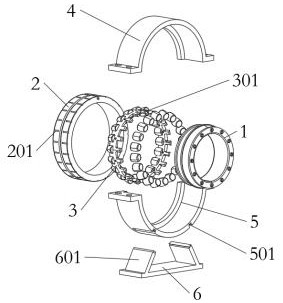

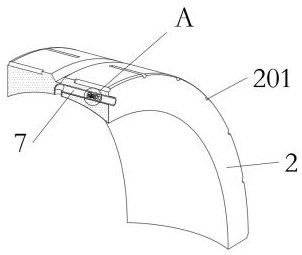

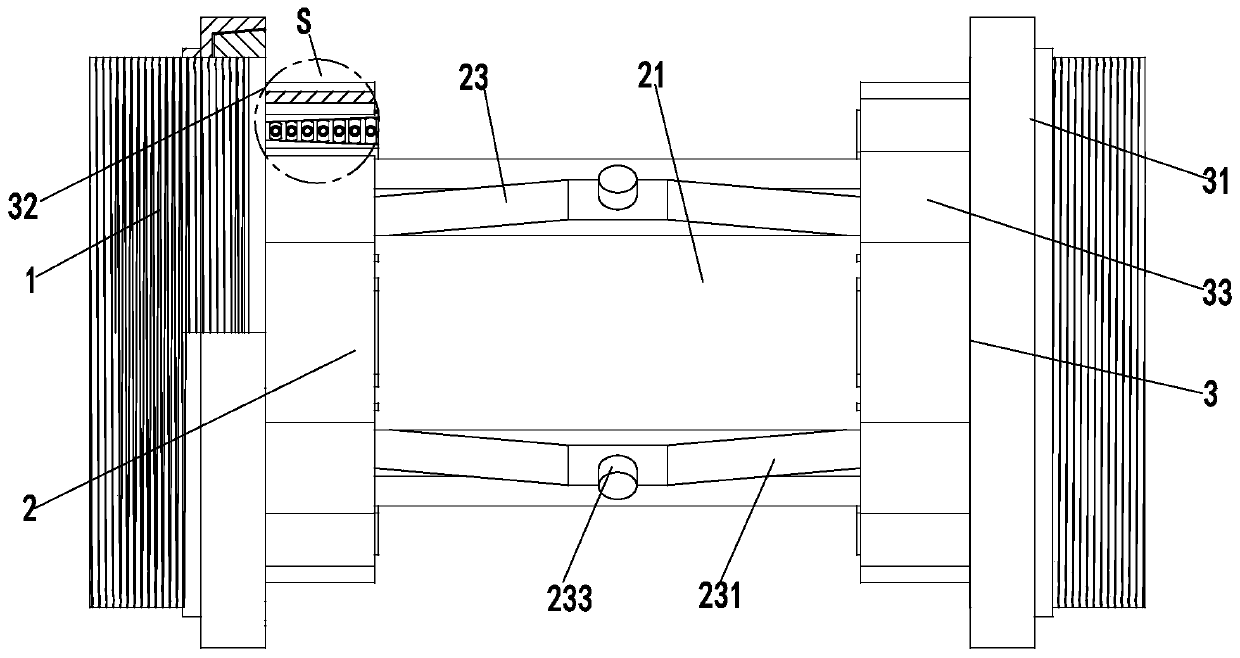

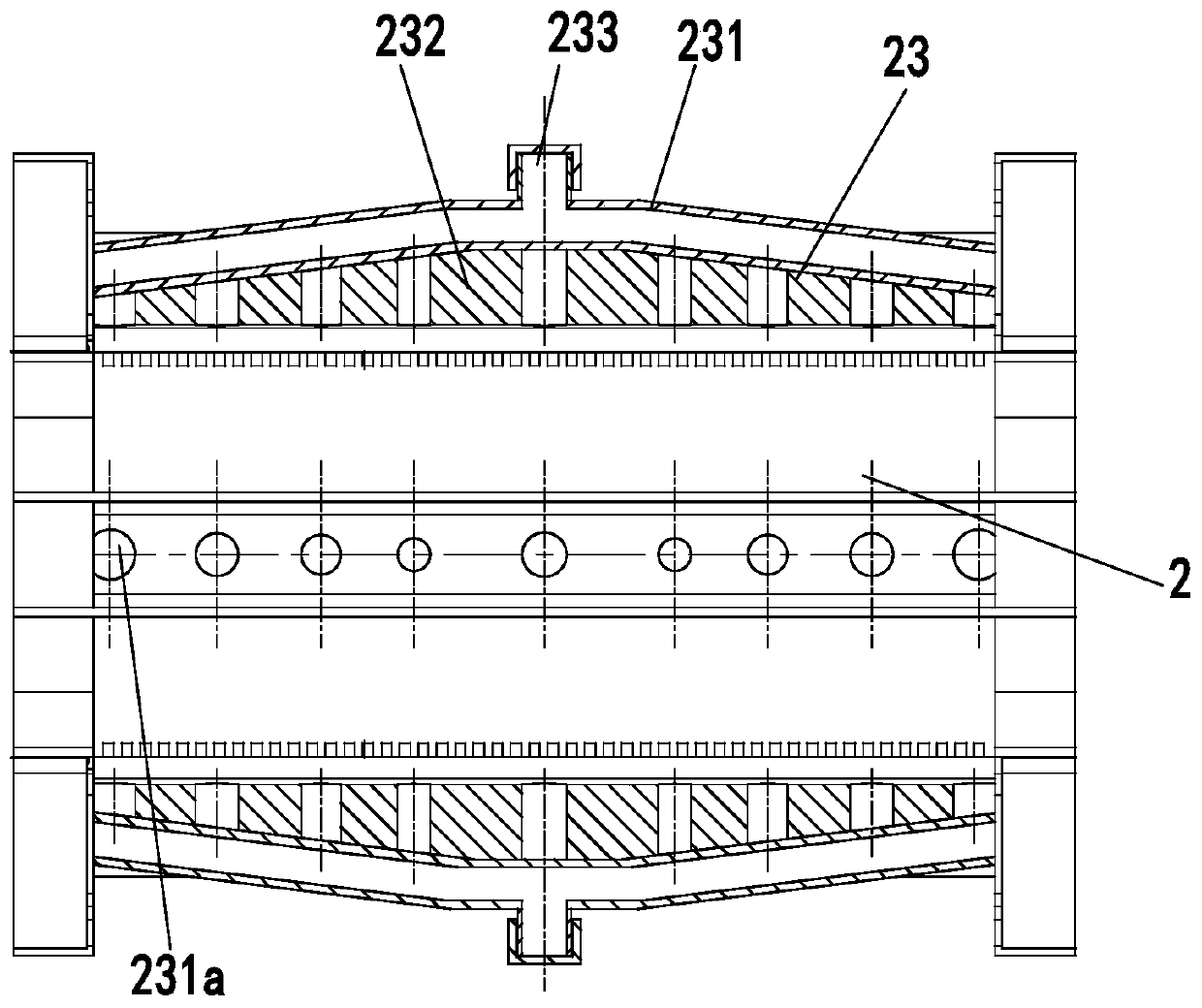

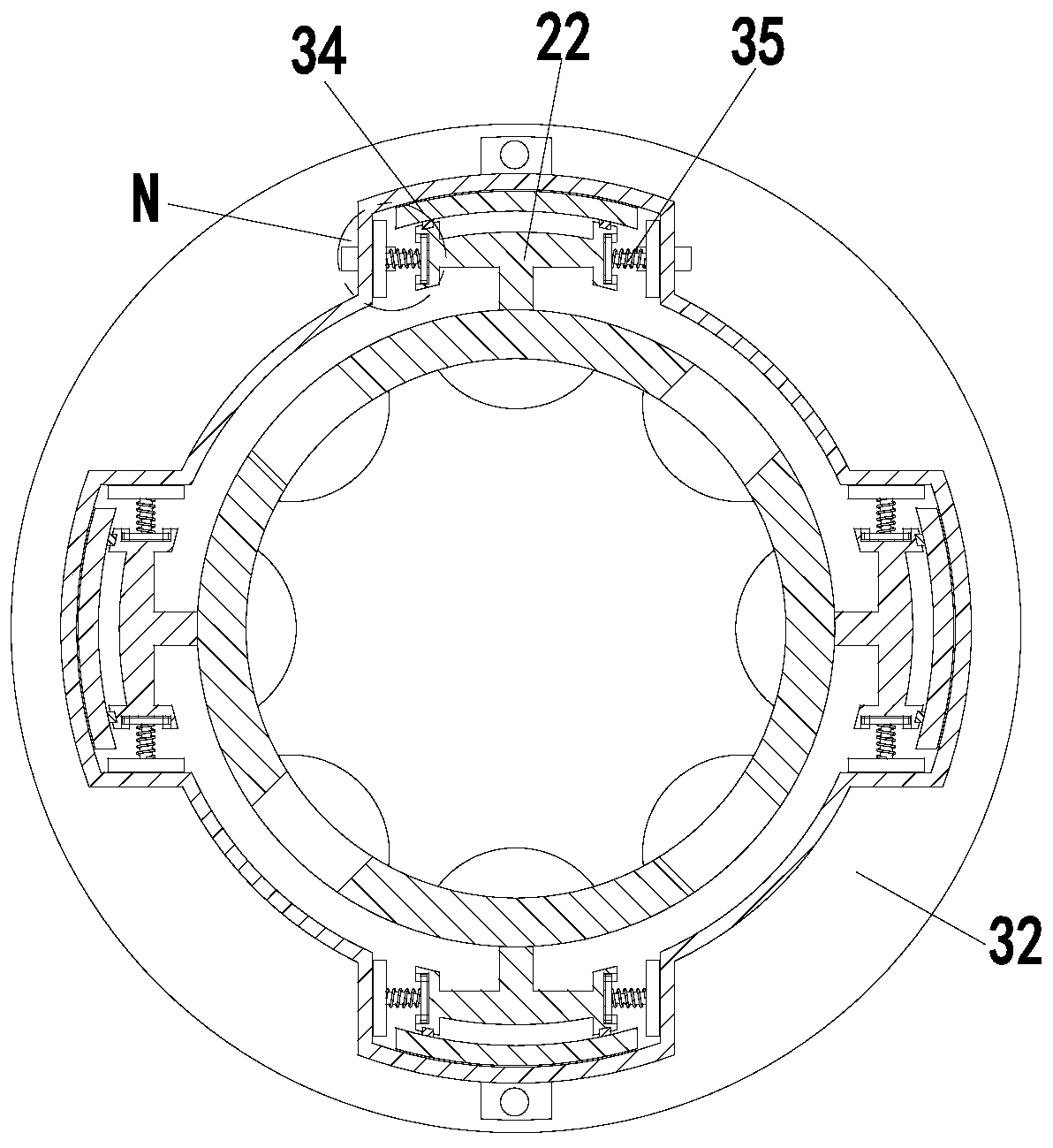

a bearing

ActiveCN110219895BStable supportStable jobBearing assemblyEngine lubricationClassical mechanicsScrew thread

The invention relates to a bearing. Bearing bodies, isolating sleeves and connecting mechanisms are included. Threads are arranged on the outer walls of the bearing bodies. The number of the bearing bodies is two. The isolating sleeves are arranged between the two bearing bodies through the connecting mechanisms. Each isolating sleeve comprises a sleeve body, clamping connection blocks and a lubricating frame. Each connecting mechanism comprises a pressing lantern ring, a base plate, loosening and tightening rings, limiting plates and connecting branch chains. Each connecting branch chain comprises a work plate, a connecting spring, a telescopic rod, a clamping plate and a clamping block. The isolating sleeves are detachably arranged between the bearing bodies, so that supporting force supplied to a rotation shaft is higher, accordingly, stability in the rotation shaft work process can be improved, and the bearing is suitable for the rotation shaft with large span. The bearing bodies are provided with the pressing lantern rings and the base plates in a left-right symmetry manner, a proper number of isolating sleeves can be installed according to the actual work need of the rotationshaft, and it is guaranteed that the rotation shaft stably works.

Owner:温州天纳福汽车轴承股份有限公司

Refrigerant for replacing R32 and application thereof

InactiveCN113549425ALow water solubilityExtended service lifeHeat-exchange elementsEngineeringAqueous solubility

The invention discloses a refrigerant for replacing R32 and application thereof. The refrigerant for replacing R32 comprises propane, fluoroethane, pentafluoroethane, trifluoroiodomethane and fluorosilicone oil. In the technical scheme of the invention, the refrigerant for replacing R32 is obtained by an applicant through a large number of tests and screening, and is prepared by mixing five components in a specific proportion, and the water solubility of each component of the refrigerant for replacing R32 is small, does not generate chemical action with lubricating oil in original refrigeration equipment, and is compatible with the lubricating oil in the original refrigeration equipment; the fluorosilicone oil in the refrigerant for replacing R32 can enable a compressor to be more lubricated, and the service life of the compressor can be prolonged.

Owner:中节硕能科技湖北有限公司

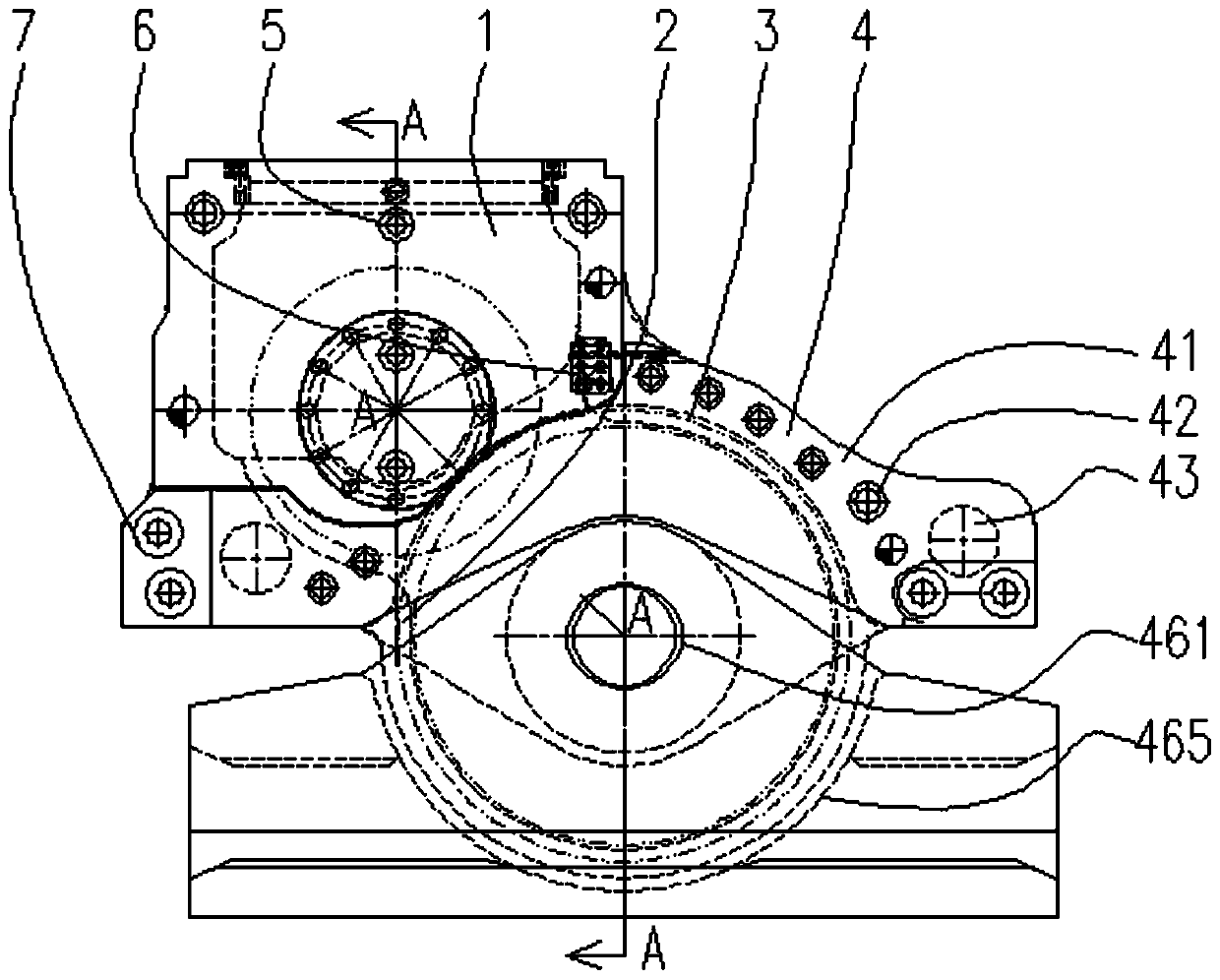

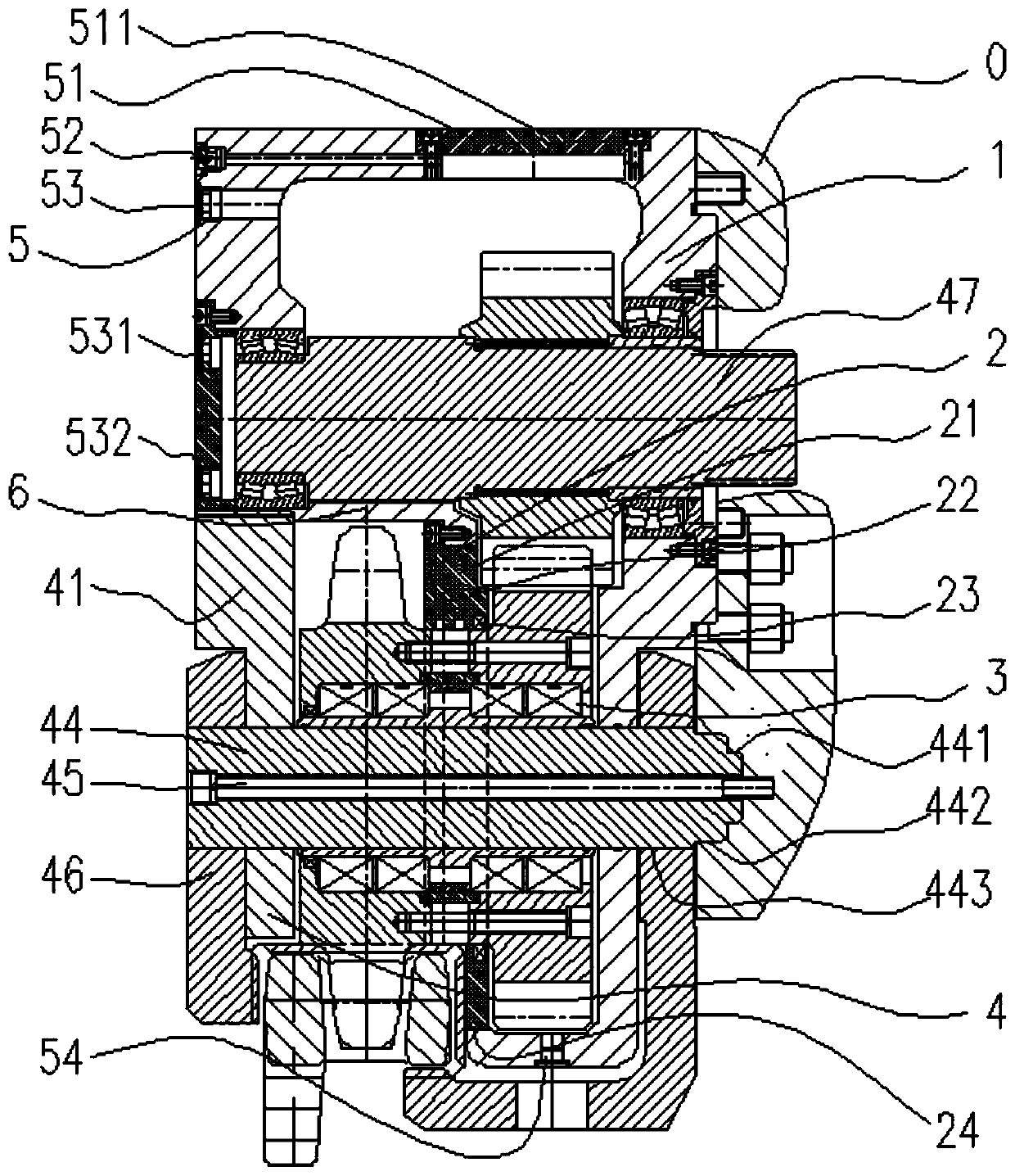

Automobile tie rod assembly

ActiveCN104192205BSimple structureImprove bearing strengthSteering linkagesPivotal connectionsMechanical engineeringLubrication

Owner:WUHU NANDA AUTO IND

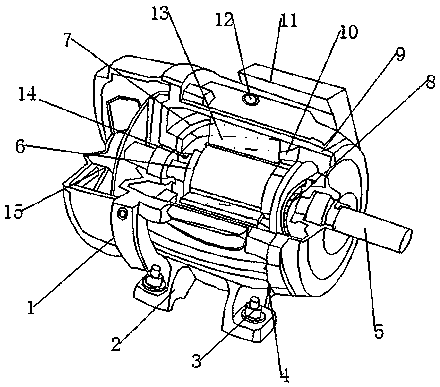

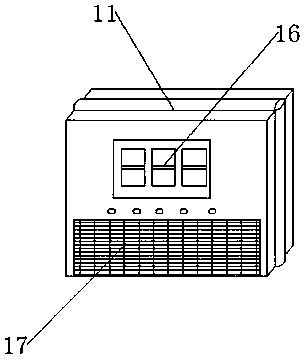

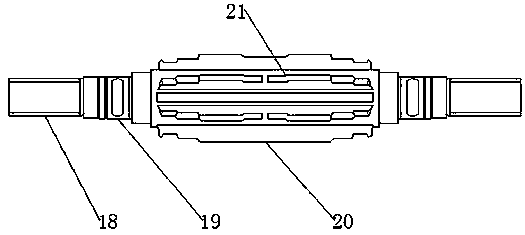

A permanent magnet motor with long service life

InactiveCN109256885AExtended service lifeReduce overheating damageStructural associationMechanical energy handlingEngineeringPermanent magnet motor

The invention discloses a permanent magnet motor with long service life, including a motor body, the outside of the motor body is provided with a motor shell, A motor support is arranged at the bottomend of the motor shell, the middle end of the motor support is provided with a fixing bolt, A top middle end of the motor shell is provided with an oil filling hole, A motor protector is arranged atthe top end of the motor shell, A display panel is arranged in the middle of one end of the motor protector, the bottom end of the display panel is provided with an alarm, An oil groove is arranged onthe inner side of the motor housing, A motor shaft is arranged in the middle of the side end of the motor body, The built-in sensor is arranged on the side of the rotor winding, and the temperature sensor can detect the temperature of the rotor winding, so that the detection is more sensitive, and the connected motor protectors are more sensitive, and can respond to the overheating more quickly,so that the overheating damage of the motor can be reduced to a certain extent, and the service life of the motor is prolonged.

Owner:CHANGZHOU INST OF TECH

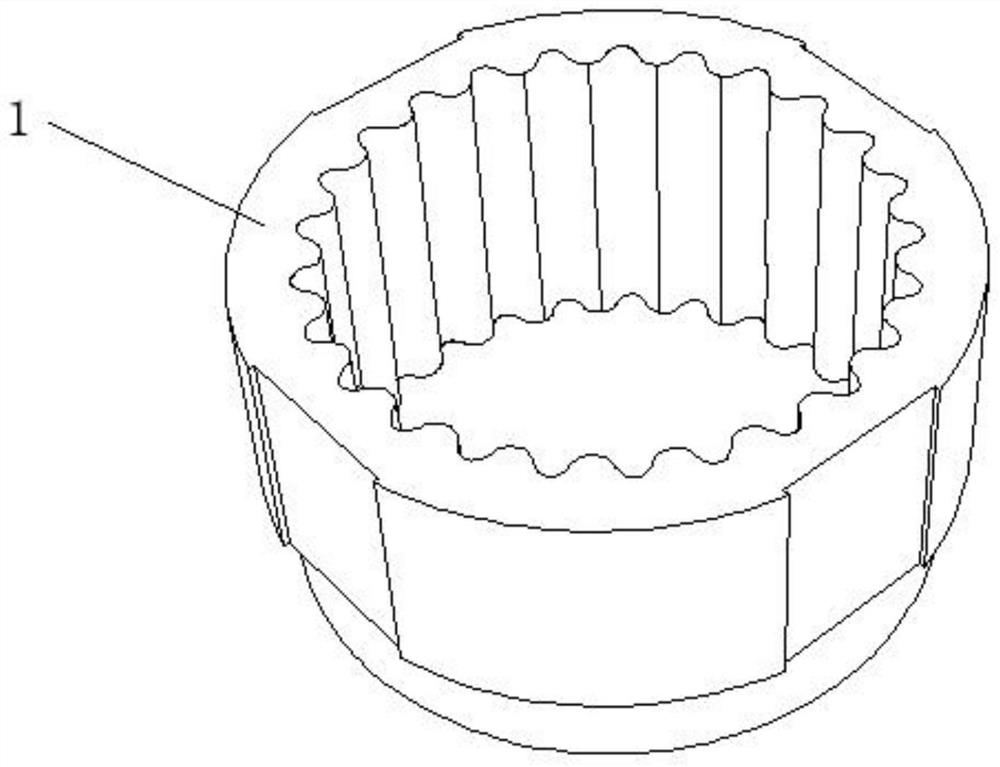

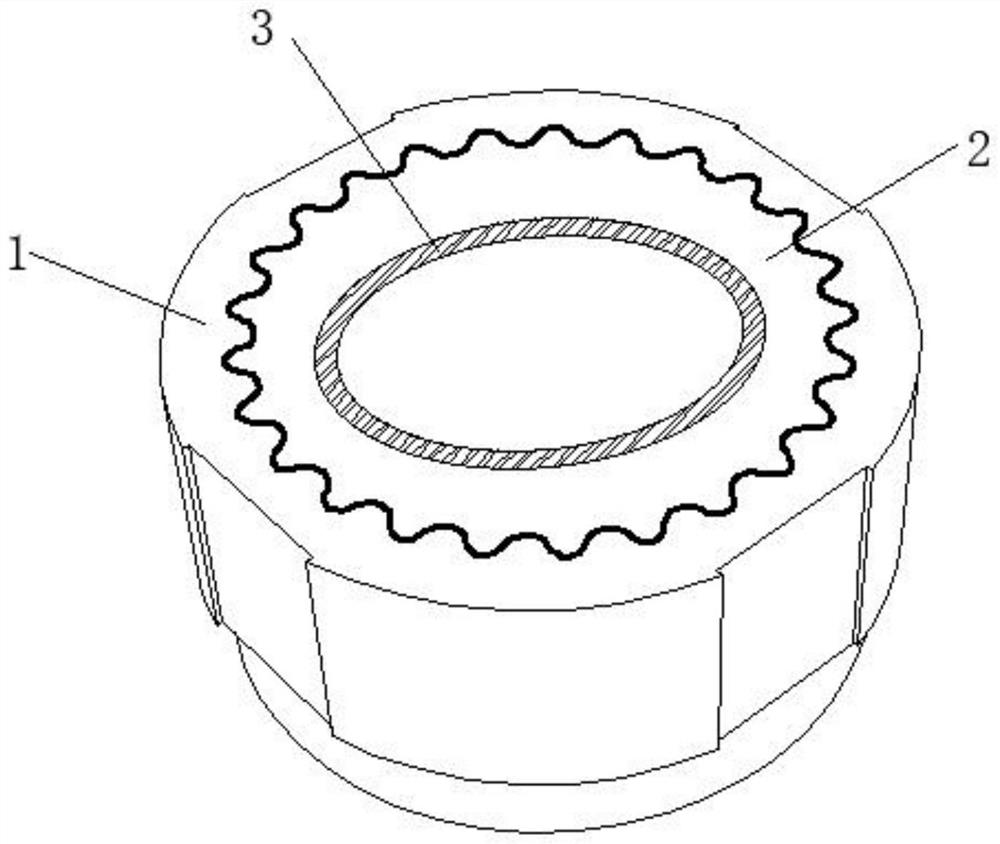

A special-shaped gear with an inner shaping layer and its processing technology

ActiveCN110345227BReduce wearGuaranteed precisionPortable liftingGear lubrication/coolingGear wheelEngineering

The invention discloses a special-shaped gear with an internal shaping layer and its processing technology, belonging to the technical field of gear processing. A special-shaped gear with an internal shaping layer includes a special-shaped gear body, and a self-fitting gear is provided inside the special-shaped gear body. Tooth surface tube, self-fitting tooth surface tube includes a self-fitting tube and a reinforcing fixed tube, the outer end of the self-fitting tube is wrapped with a self-lubricating ring and a selectively permeable film layer, a selectively permeable film layer and a self-lubricating ring There are many small oil pockets between them. After the last process of traditional gear processing, a self-fitting tooth surface operation is added. A self-fitting tooth surface tube is added on the inner side of the gear, and the self-fitting tooth surface tube is used to fit tightly Protect the gear teeth on the surface of the gear teeth, reduce the wear of the gear teeth during transportation and movement, and ensure its precision. In addition, through the setting of the self-lubricating ring on the surface of the self-fitting tooth surface tube, the gears can be adjusted when using the gears. The surface of the teeth produces comprehensive lubrication, which eliminates the separate oiling steps in traditional installation operations.

Owner:南通通途机电制造有限公司

A pipe sealing device for household decoration that facilitates subsequent cleaning

ActiveCN111503415BReduce frictional resistanceShorten the timePipe elementsCleaning processes and apparatusClassical mechanicsStructural engineering

The invention discloses a pipe sealing device for household decoration that is convenient for subsequent cleaning, and specifically relates to the field of auxiliary equipment for home decoration. A push mechanism is arranged between them, and the push mechanism includes a horizontal plate, a push rod is fixedly connected to the center of the bottom of the horizontal plate, and a sponge block is fixed at the bottom end of the push rod. The present invention utilizes the linkage between the pushing mechanism and the lubricating mechanism. During the downward movement of the sponge wiping block, the pushing mechanism drives the lubricating mechanism to rotate to lubricate and wipe the sponge wiping block passing through the lubricating mechanism. At the same time, the cleaning mechanism is linked with the pushing mechanism. When the pushing mechanism is pushed down, the cleaning mechanism does not work. When the pushing mechanism is pulled upwards, the pushing mechanism drives the cleaning structure to operate to beat the sponge block to clean up the construction debris attached to the top of the sponge block.

Owner:广州珠江建筑装饰有限公司

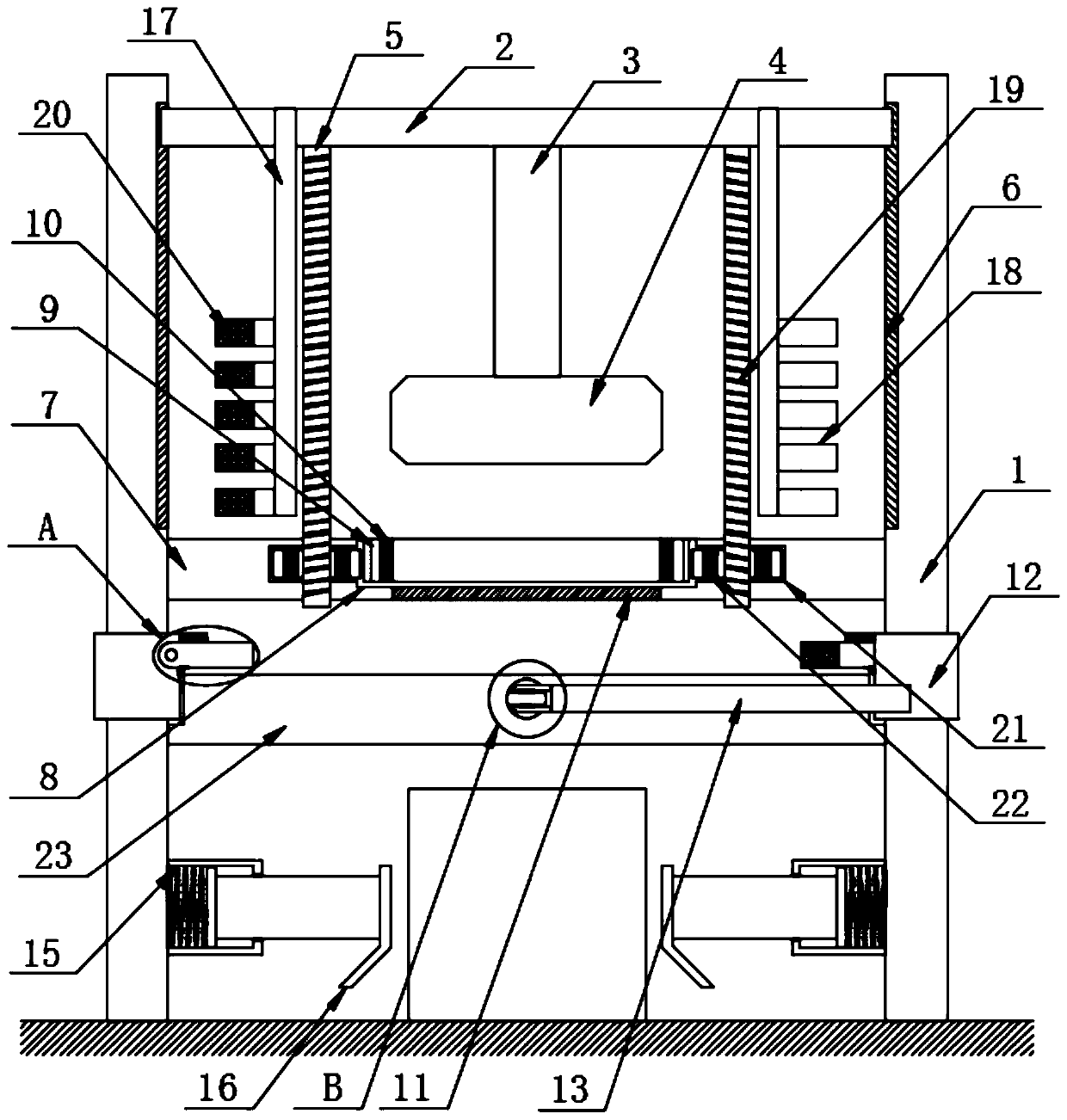

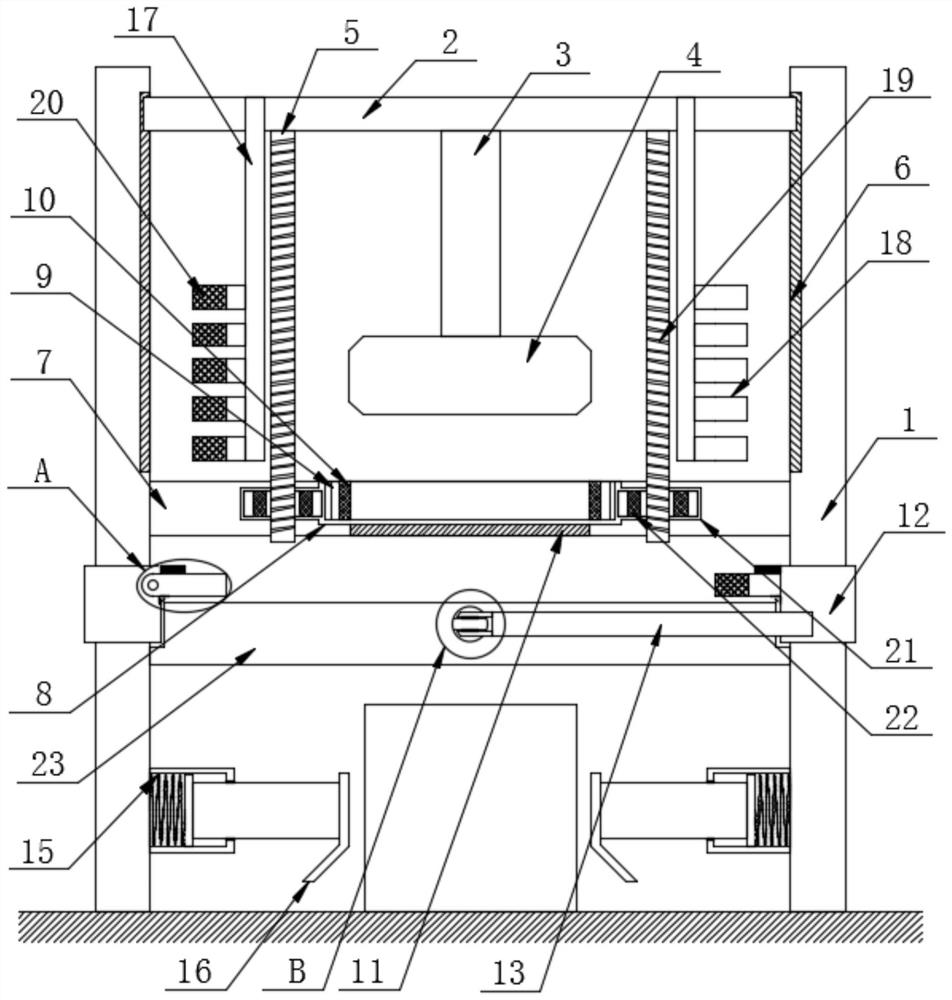

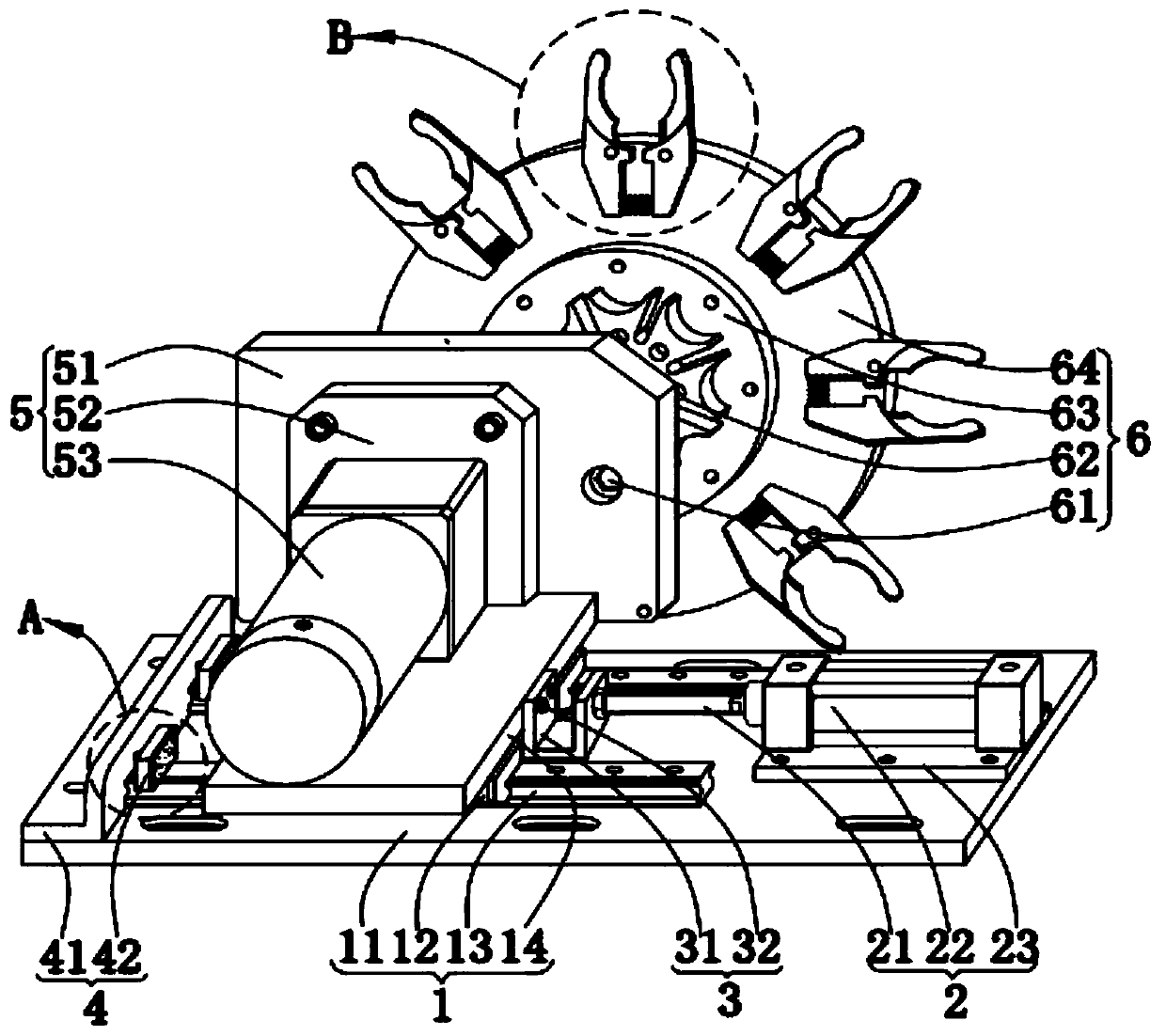

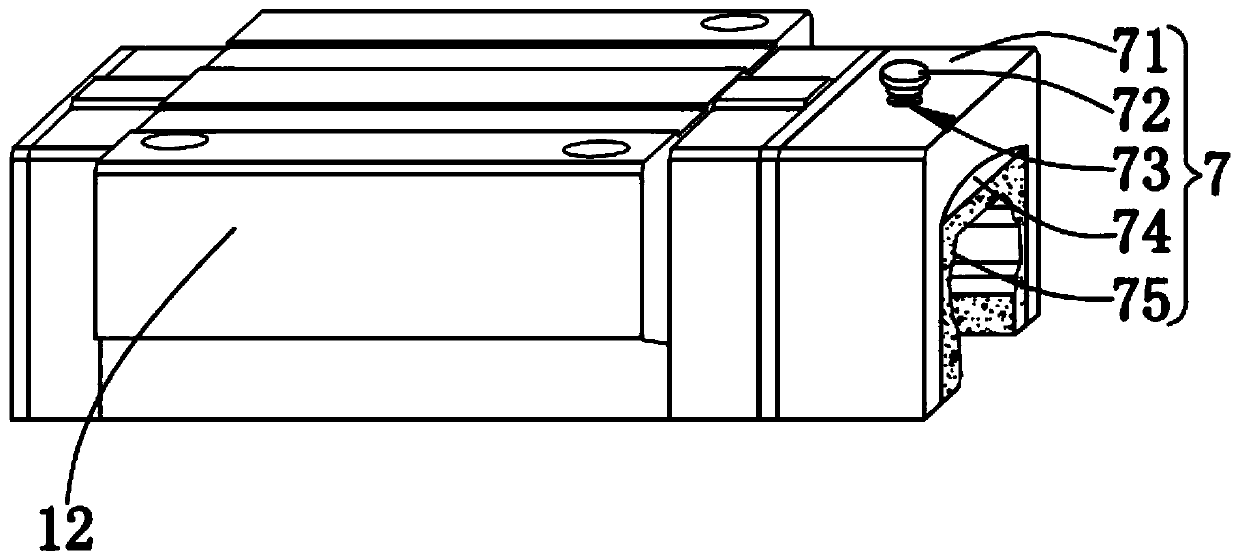

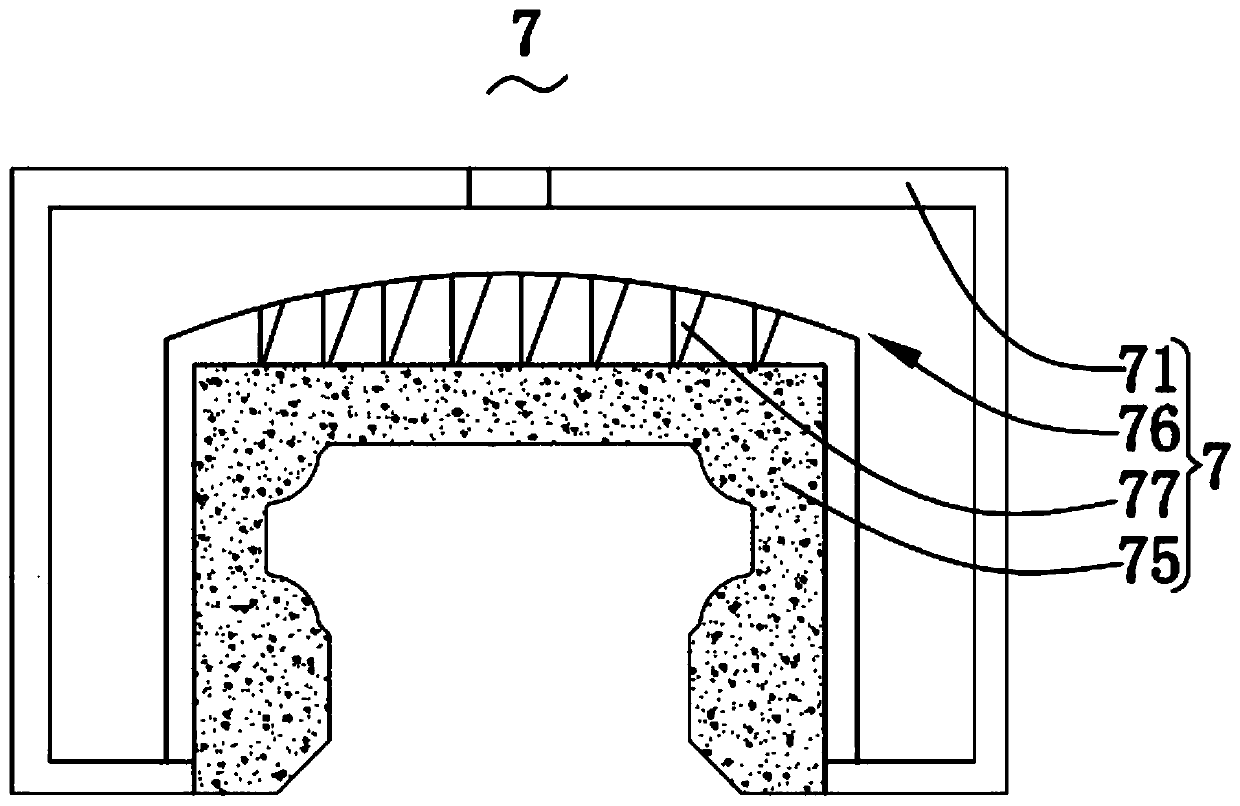

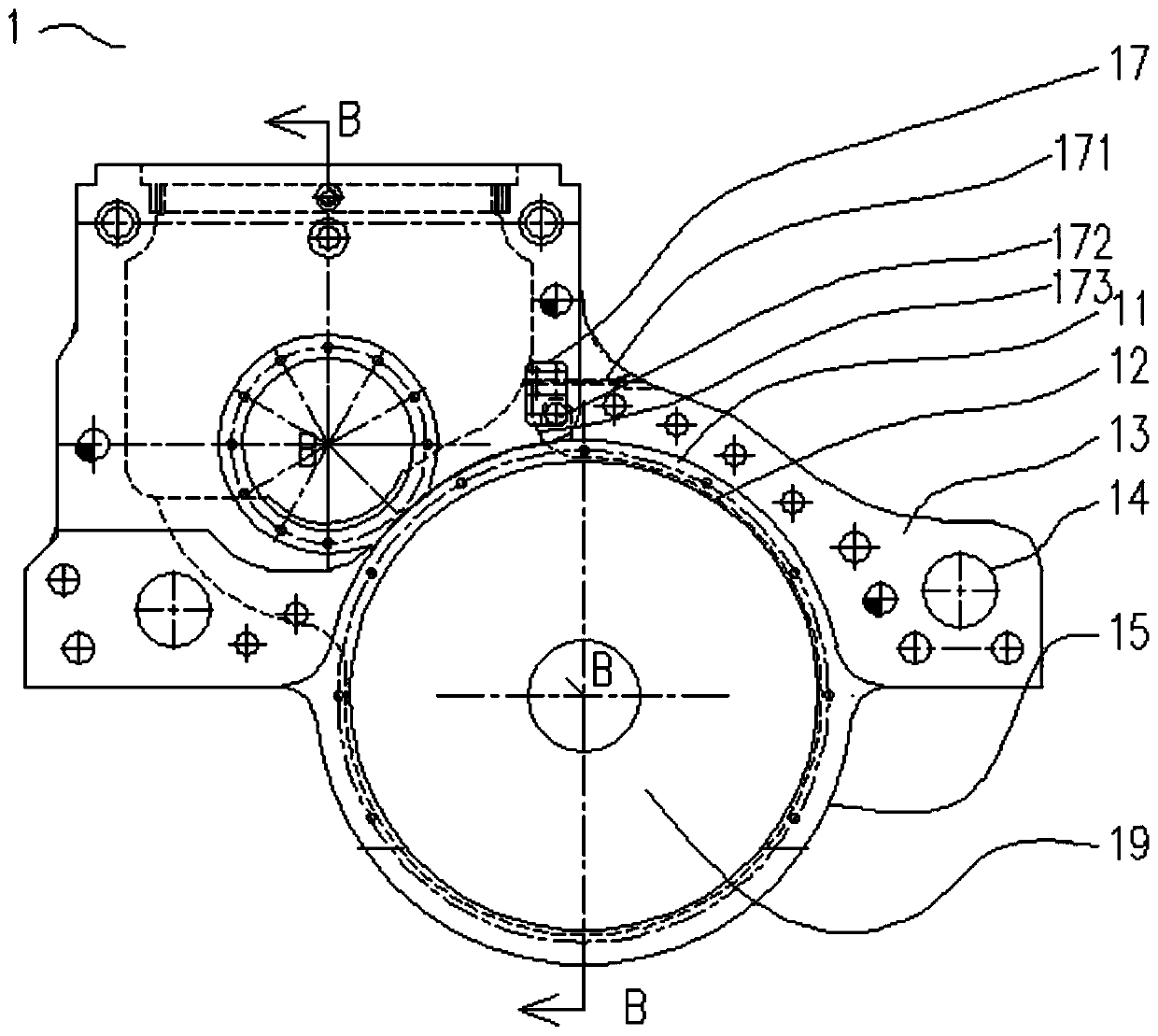

An intelligent tool magazine based on the Internet of Things

ActiveCN108907887BLess quantityPrevent leakagePositioning apparatusMaintainance and safety accessoriesNumerical controlOil can

The invention relates to the field of numerical control machining equipment, in particular to an intelligent cutter magazine based on an internet of things. The intelligent cutter magazine based on the internet of things comprises a sliding structure, a pushing structure, a connecting structure, a limiting structure, a power structure, a rotating structure, a lubricating structure and a clamping structure; the lubricating structure for lubricating the sliding structure is slidingly connected into the sliding structure for enabling a cutter head to move; the pushing structure for providing power for sliding of the sliding structure is arranged at one end of the sliding structure; and the connecting structure for connecting the sliding structure with the pushing structure is clamped betweenthe sliding structure and the pushing structure. An oil permeation pipe is of a funnel structure for effectively preventing leakage of lubricating oil caused by excessive lubricating oil; and one endof a second sponge is of an arc structure for increasing indirect contact area between the second sponge and an oil storage bin, so that the lubricating oil can be distributed on the second sponge more uniformly, and the lubricating effect is better.

Owner:OKADA SEIKI DANYANG CO LTD

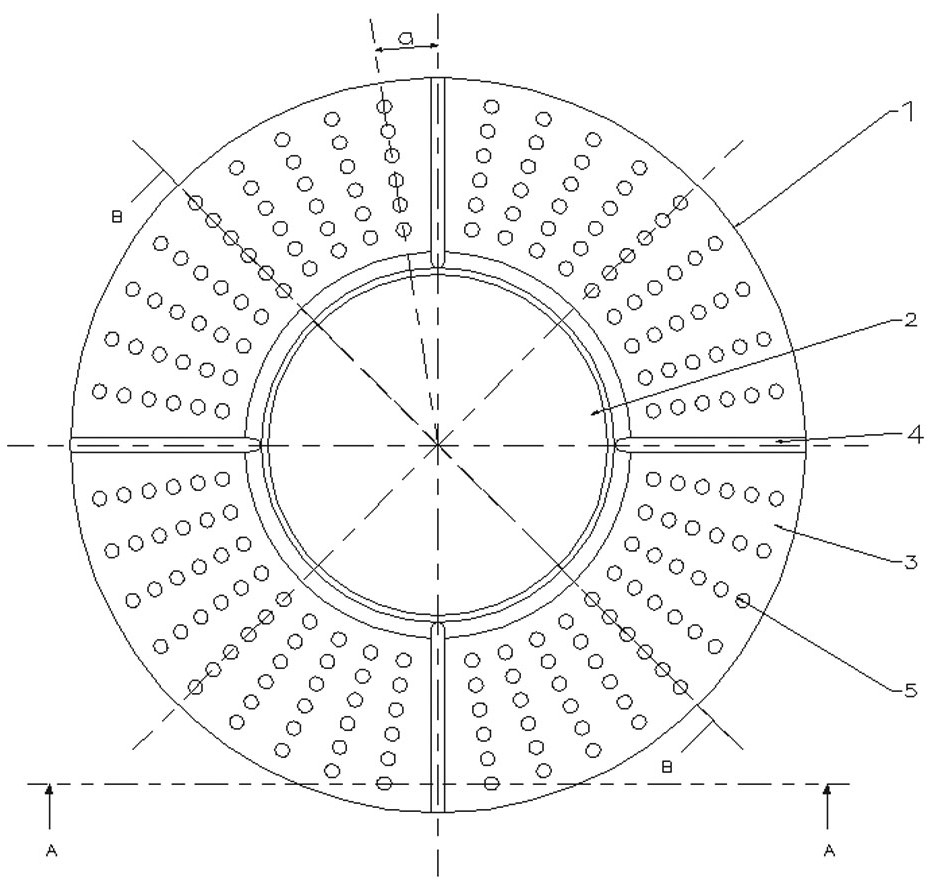

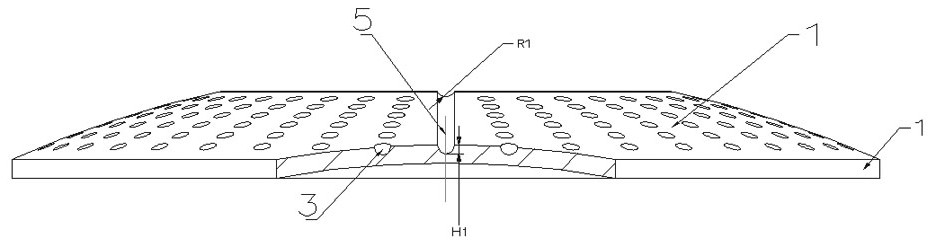

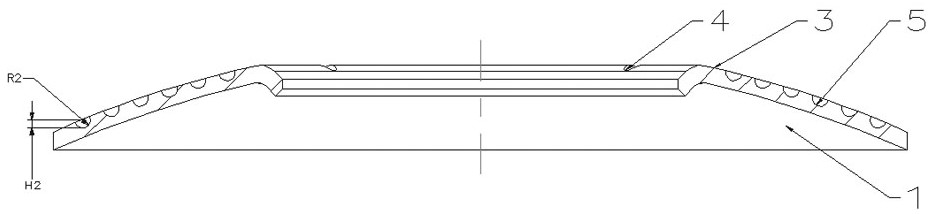

Automotive differential planetary gear gasket with multiple pits and multiple oil grooves

PendingCN112283315AImprove lubrication conditionsImprove securityGear lubrication/coolingDifferential gearingsGear wheelPhysics

The invention discloses an automotive differential planetary gear gasket with multiple pits and multiple oil grooves. A gasket body is taken as a carrier, a coaxial circular inner hole is formed in the middle of the gasket body, and the upward surface of the gasket body is an outwards-convex spherical surface. The structure of the automotive differential planetary gear gasket is characterized in that the pits evenly distributed in the outwards-convex spherical surface are alternated by the four radial oil grooves. The oil grooves are linear inwards-concave arc-shaped grooves, the four oil grooves formed in the outwards-convex spherical surface coincide with angle bisectors of four quadrants, one end of each oil groove communicates with the inner hole, and the other end of each oil groove is stopped on the outer edge of the gasket body. The pits are spherical-crown-shaped counter bores, the pits are evenly distributed in the end face, except for the oil grooves, of the outwards-convex spherical surface, the included angles alpha between the spherical centers of the pits located in the two sides of the oil grooves in the circumferential direction are equal, 5-7 pits are formed in each angle bisector in the four quadrants of the outwards-convex spherical surface, and the radial intervals between the adjacent pits are equal. The oil grooves are used for separating pit groups, and lubricating oil introduced by the oil grooves is supplemented to the pits nearby, so that the lubricating condition of the outwards-convex spherical surface is remarkably improved.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

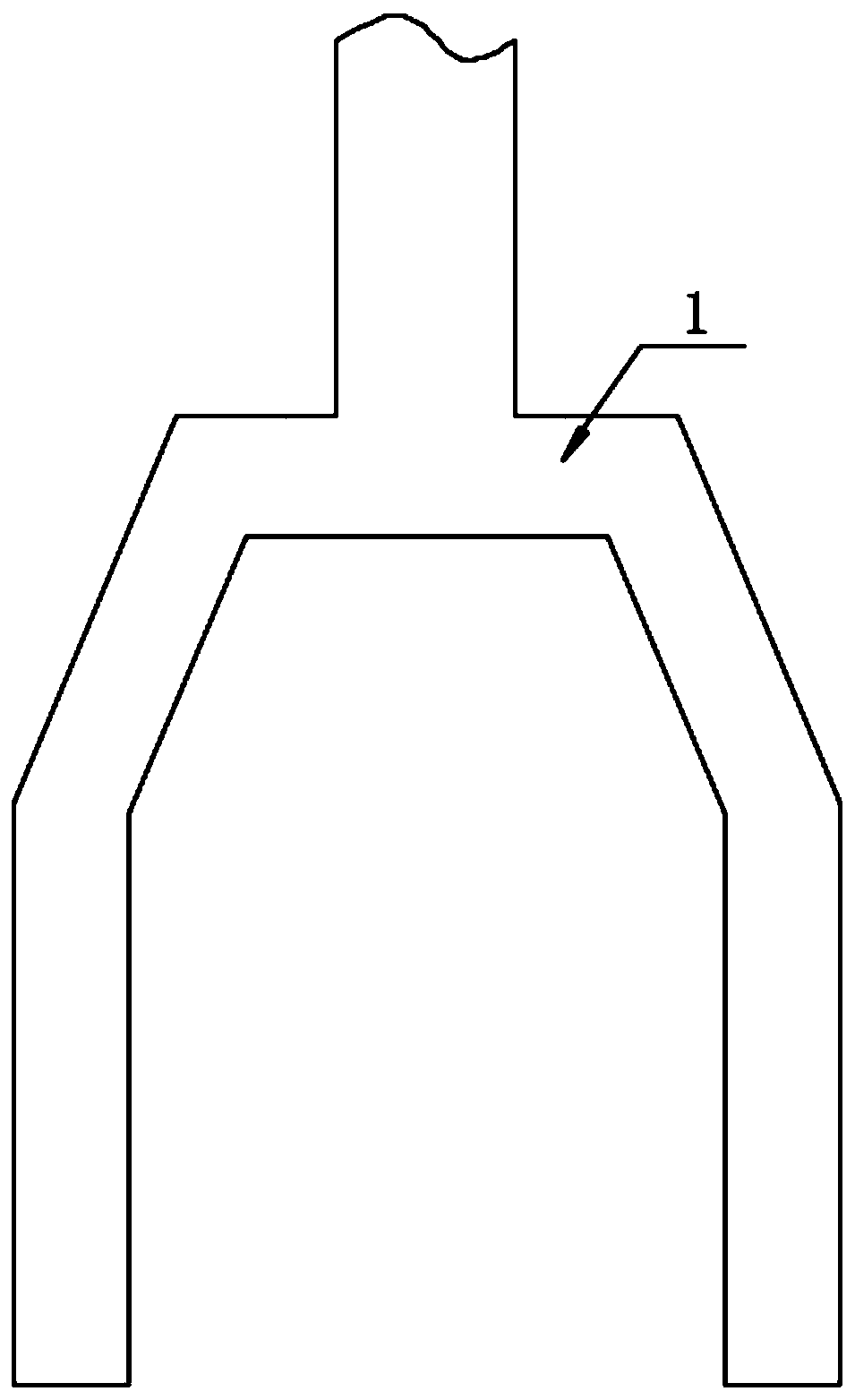

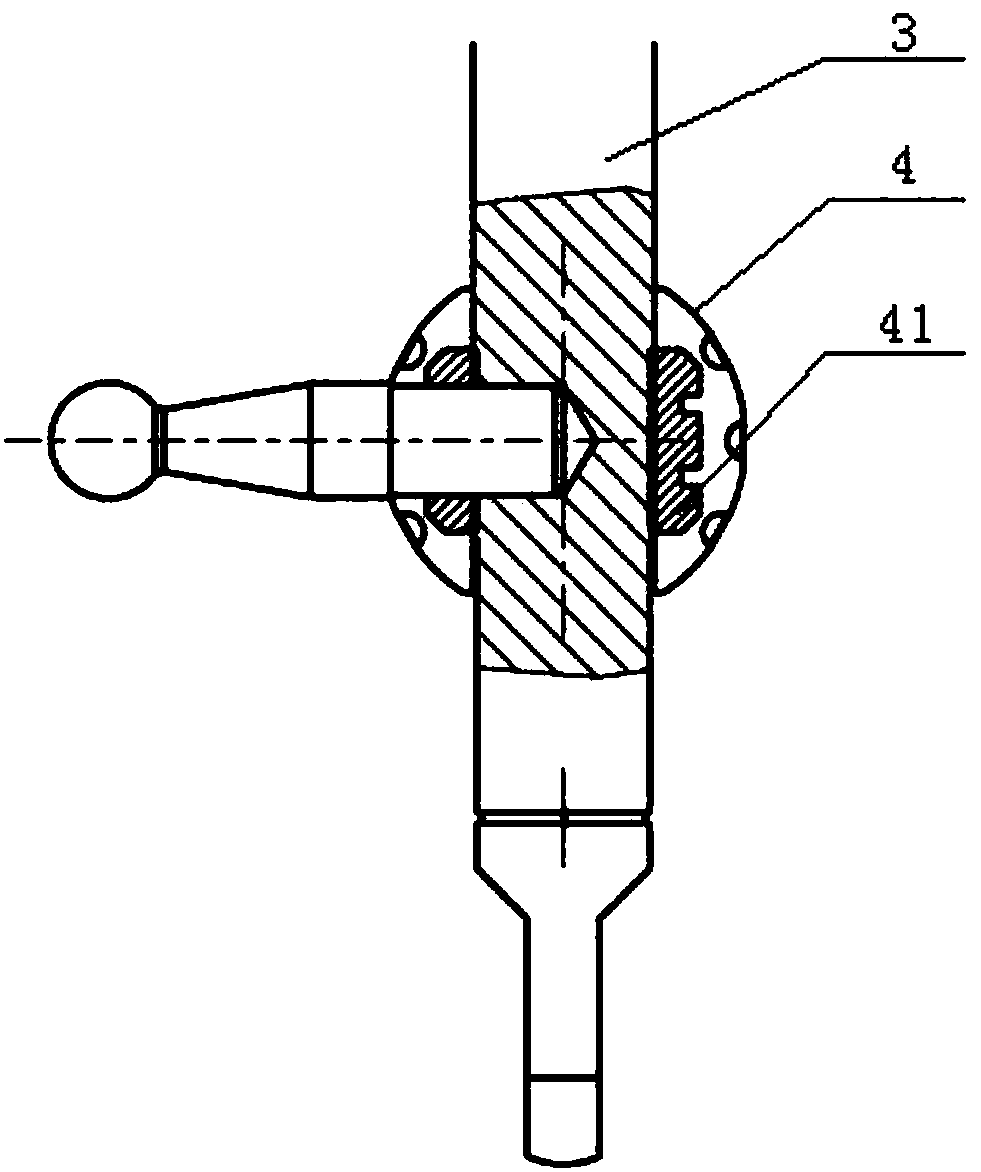

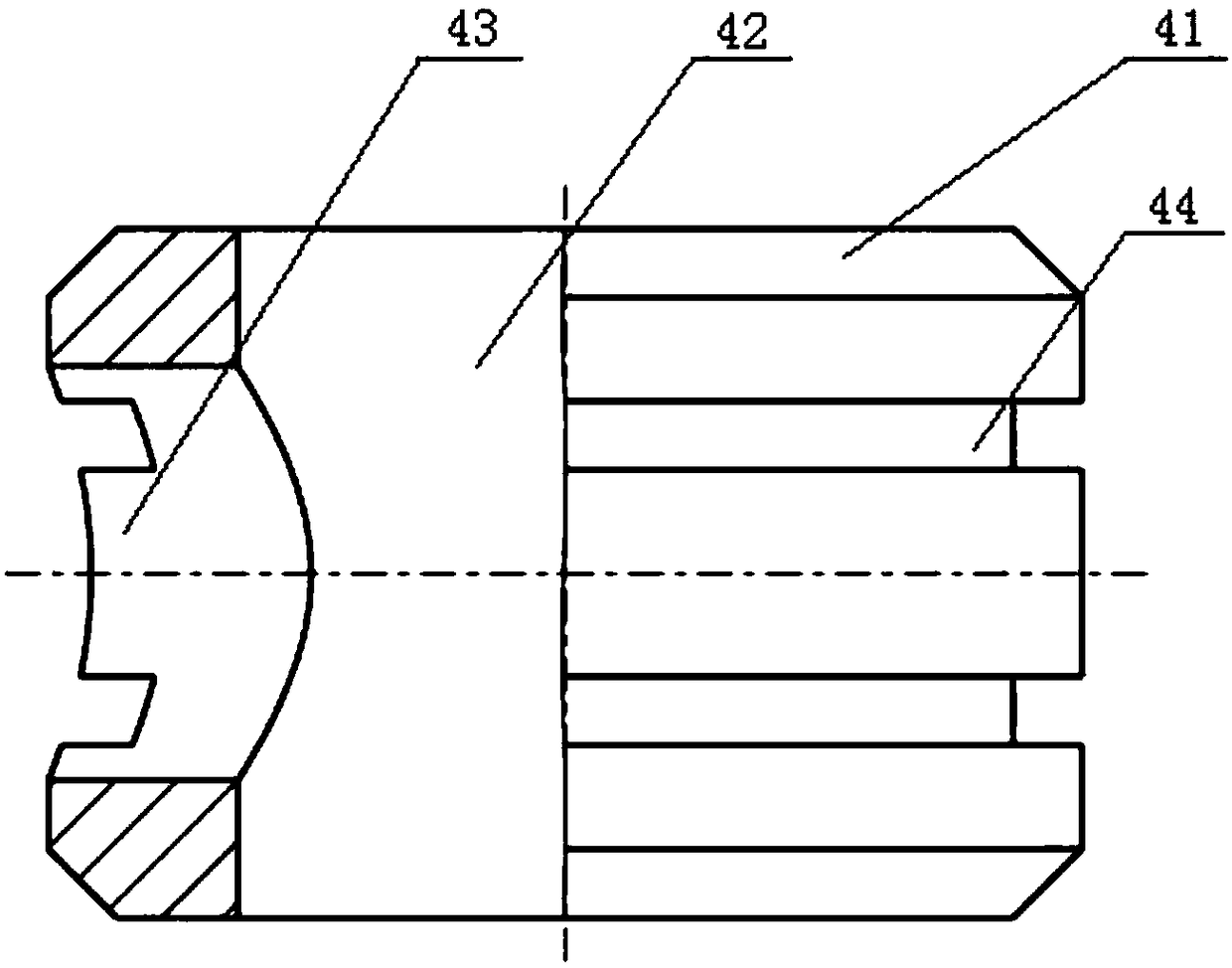

Flexible shaft control device with ball head

InactiveCN109307059ALow costImprove lubrication environmentGearing controlEngine lubricationBall jointEngineering

The invention relates to a flexible shaft control device with a ball head. The flexible shaft control device comprises a manipulating supporting seat, a control rod, a nylon ball joint and a limitingblock, wherein the control rod penetrates through a middle part through hole of the manipulating supporting seat; the nylon ball joint is arranged at the middle part of the control rod; the limiting block is arranged at a position located above the ball joint, of the control rod; a plurality of ball sockets are uniformly distributed on the outer surface of the nylon ball joint; the nylon ball joint cooperates with an upper ball seat and a lower ball seat on the manipulating supporting seat; and the top surface and the bottom surface of the nylon ball joint are level surfaces. Through the adoption of the flexible shaft control device disclosed by the invention, the situations that the control rod is stable and has hand feeling, and gear can be correctly sought can be guaranteed.

Owner:饶皇

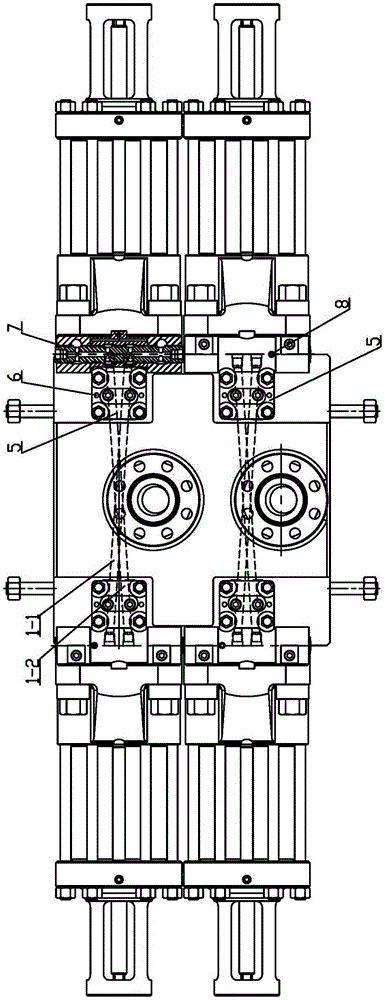

Travelling part of split-cavity structure

PendingCN110159705ASolve serious wear and tearSolve the problem of longevityGear lubrication/coolingToothed gearingsDrive shaftEngineering

The invention relates to a travelling part with a split-cavity structure. The shell of the travelling part is provided with an oil pool, a connecting plate is fixed to the shell, an open cavity is defined by the lower part of the connecting plate and the front side wall of the lower part of the oil pool, and a driving shaft is supported on the shell through a bearing; a driving gear is externallymeshed with the driven gear, a travelling wheel and the driven gear are coaxially fixed, and the travelling wheel and the driven gear are correspondingly and rotationally connected to the same supporting shaft through bearings; the supporting shaft penetrates through the front side walls and the rear side walls of the connecting plate and the oil pool, the driving gear and the driven gear are located in an oil pool cavity, and the travelling wheel is located in the open cavity; and the front side wall and the rear side wall of a guide sliding shoe are arranged on the supporting shaft in a sleeving mode, and gaps are reserved between the guide sliding shoe and the connecting plate, and between the guide sliding shoe and the corresponding surfaces of the lower part of the oil pool. Accordingto the travelling part, the problems that the abrasion loss of the travelling part is serious and the service life of the whole equipment is short when a roller type mining machine is used for mininghigh-hardness and high-abrasion-resistance mineral materials can be solved.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

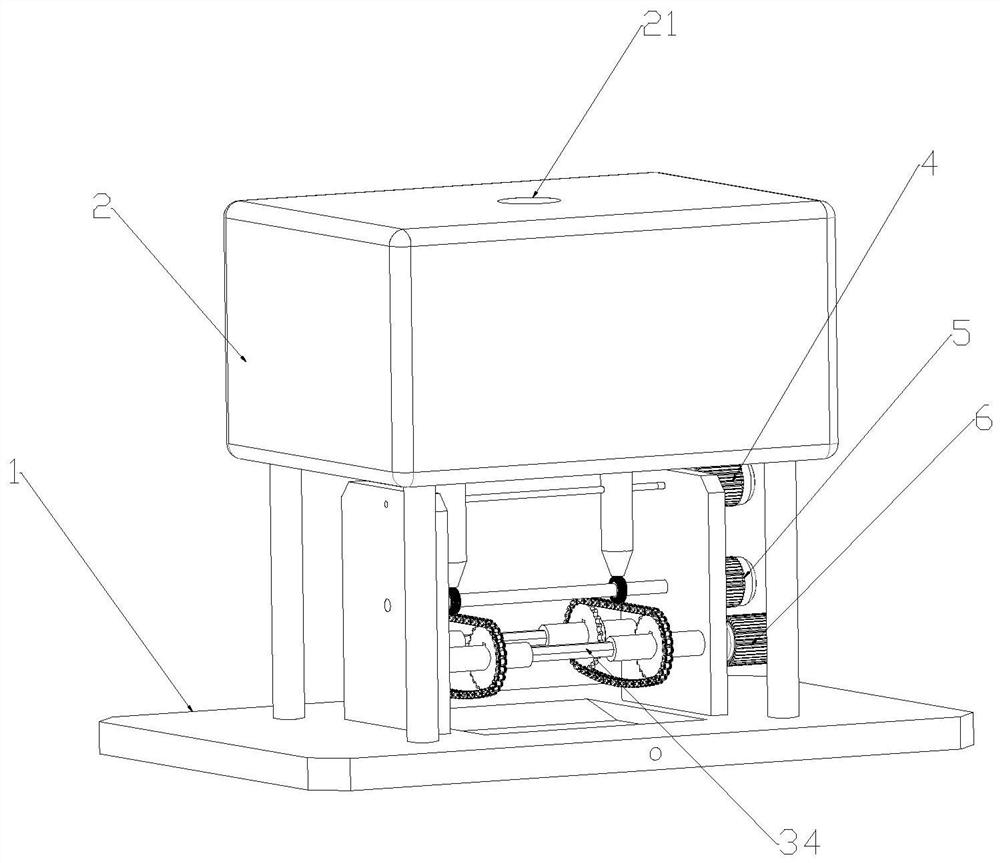

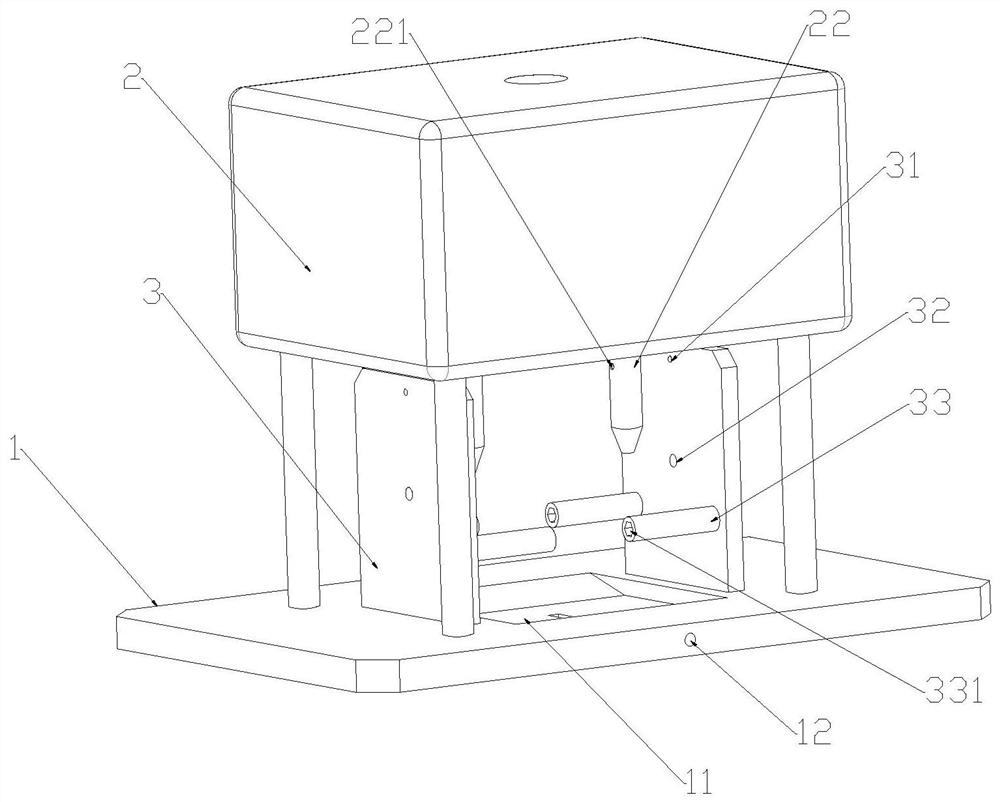

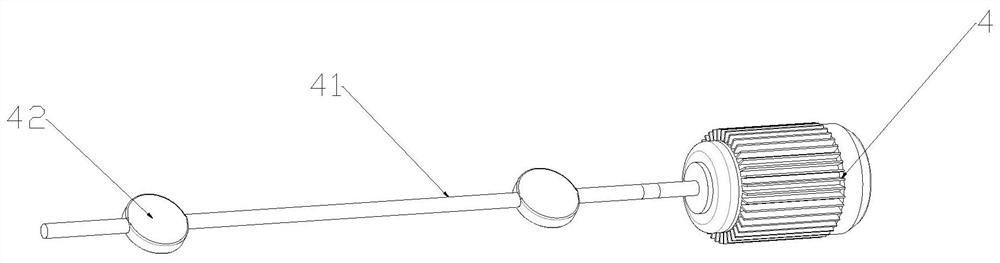

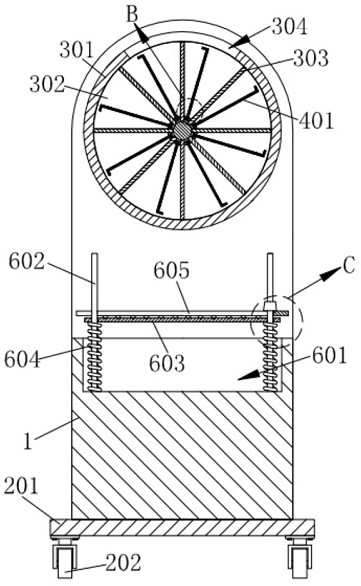

Lubricating device for digital steel chain

PendingCN113324022AComprehensive lubricationImprove work efficiencyGearing detailsElectric machineryEngineering

The invention relates to the field of chain lubrication, in particular to a lubricating device for a digital steel chain. The lubricating device comprises a bottom plate, two support plates are arranged at the upper end of the bottom plate, two support rods are rotatably arranged on the inner walls of the support plates respectively, chain wheels are detachably mounted on the support rods, and chains are connected to the chain wheels. A lubricating oil tank is arranged above the bottom plate, an oil outlet with the flow speed adjustable is formed in the bottom end of the lubricating oil tank, the oil outlet is formed over the chain, and a brush is arranged between the oil outlet and the chain and makes contact with the chain. When the lubricating device is used, the oil outlet is adjusted to be proper in oil outlet amount to enable the oil to fall on the brush, and the brush rotates to lubricate the chain. In the lubricating process, the chain is driven by a third motor to rotate, all chain links of the chain are lubricated, after lubricating is completed, the supporting column slides into the supporting rod, the chain wheel and the chain are detached, the next chain wheel and the next chain are replaced, comprehensive lubricating can be achieved, the oil outlet position can be controlled, and the working efficiency is improved.

Owner:安徽长江钢铁股份有限公司

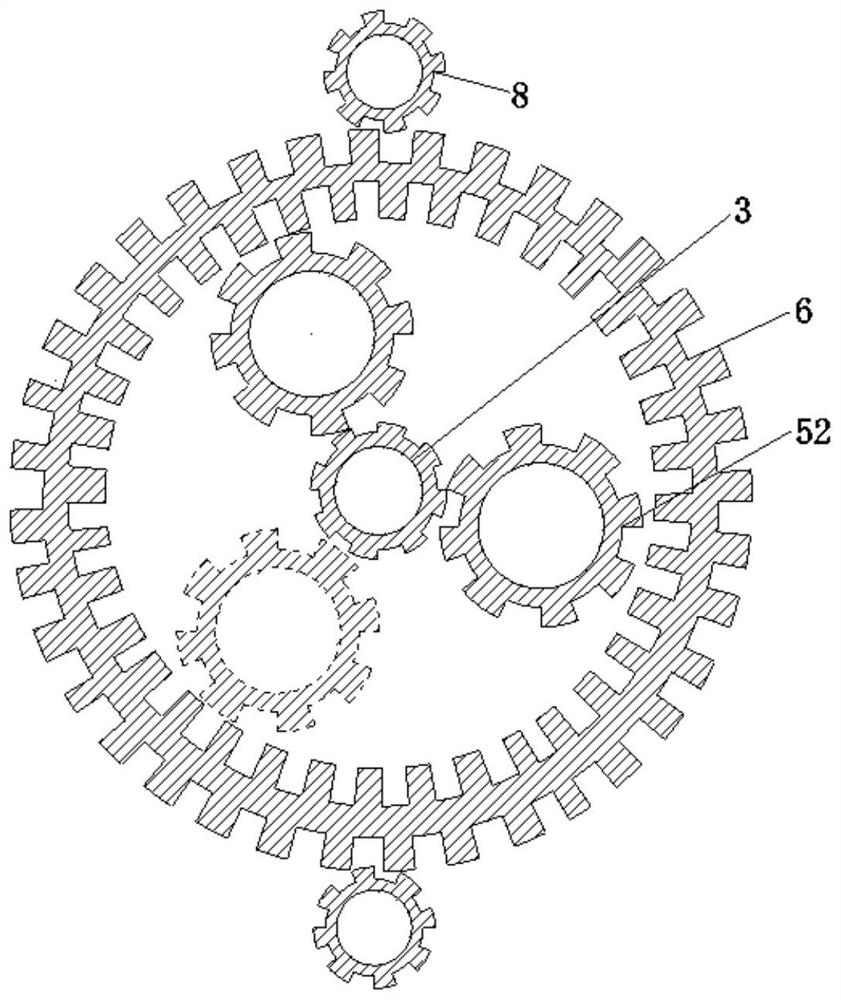

Novel transmission system based on planetary gears for energy feedback

PendingCN111677825AEasy to installHighly integratedToothed gearingsGear lubrication/coolingElectric machineryEnergy feedback

The invention discloses a novel transmission system based on planetary gears for energy feedback. The system involves an outer fluted disc, a sun gear, the plurality of planetary gears, a gear ring and at least one motor gear, wherein the outside of the outer fluted disc is coaxially provided with a shaft body I, and the outer fluted disc is provided with a plurality of inner disc teeth; the sun gear and the shaft body I are coaxially arranged, the sun gear is arranged on the inner side of the outer fluted disc, and a shaft body II is arranged on the sun gear in a penetrating mode; the axial sections of the plurality of planetary gears are I-shaped, the planetary gears comprise a planet gear I, a planet gear II and a connecting shaft, the planet gear I is in gear mesh with the inner disc teeth, and the planet gear I and the planet gear II are in gear mesh with the sun gear; the gear ring and the sun gear are coaxially arranged, the gear ring is provided with inner ring teeth and outerring teeth, a planet carrier is arranged in the gear ring, the connecting shaft is arranged on an inlaying position on the planet carrier in a penetrating mode, and the inner ring teeth are in gear mesh with the planet gear II; and the motor gears are in gear mesh with the outer ring teeth, a shaft body III is arranged on each motor gear in a penetrating mode, and a motor for driving each shaft body III to rotate is arranged on the shaft body III. The system has the beneficial effects of being convenient to install, high in integration degree, stable and efficient in transmission and capable of achieving two-way transmission.

Owner:徐亚男 +1

Polyethylene glycol monooleate fully-synthetic cutting fluid and preparation method thereof

ActiveCN102776060BComprehensive lubricationExtend the life cycleLubricant compositionPolyethylene glycolMaterials science

The invention relates to a cutting fluid for metal processing, and particularly relates to a polyethylene glycol monooleate fully-synthetic cutting fluid and a preparation method thereof. Polyethylene glycol monooleate is used as a lubricating agent, and borate generated by boric acid and monoethanolamine and triazine amino-acid ester are combined to form an anti-rust component which has better anti-rust property, thus solving the defects of poor lubricating property, easy deterioration and smelliness and short service life of polyethylene glycol lubricating agents, polyether lubricating agents, oleic acid soap lubricating agents and sulfonated caster oil lubricating agents, and further achieving a corrosion inhibition and synergy function by adding a proper amount of benzotriazole copper corrosion inhibitor and other anti-rust agents. The fully-synthetic cutting fluid prepared from the raw materials is complete in property, has excellent hard water resistance, can be used under a high hard water environment, is high in pH buffer capacity, is stable in quality, has excellent lubricating, anti-rust and anti-corrosion functions, belongs to an environment-friendly product, can be biodegraded, is suitable for various kinds of machining, and is especially suitable for various machining processes of a grinder.

Owner:温州宝罗润滑材料有限公司

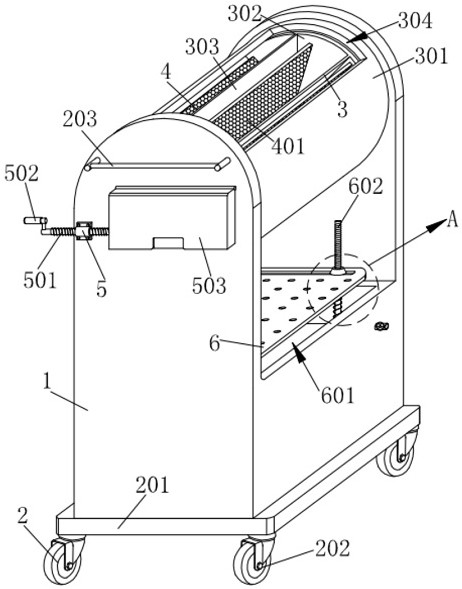

A kind of accessories storage device for motorcycle production workshop

The invention relates to the technical field of motorcycle production accessories storage, in particular to a motorcycle production workshop accessories storage device, comprising a fixing frame, on which a moving mechanism for facilitating the movement of the whole mechanism is installed, and the fixing frame is mounted on the fixing frame. A accommodating mechanism for storing a plurality of motorcycle circuit assemblies separately is installed, a plurality of clamping mechanisms for clamping the circuit assemblies are installed in an annular array on the accommodating mechanism, and one side of the fixing frame is installed There is a driving mechanism for driving the accommodating mechanism, the driving mechanism is connected with the accommodating mechanism, the fixing frame is installed with a limiting mechanism for limiting the position of the driving mechanism, and the accommodating mechanism can realize the total number of motorcycle lines. The components are placed separately to avoid multiple wire bundles being cluttered together, which is not conducive to taking, waste of time, and easy to damage the wire harnesses, and the clamping mechanism on the accommodating mechanism is conducive to clamping the wire harnesses of different volumes, avoiding incomplete clamping. Causes damage to the terminals on the harness.

Owner:徐州荣腾智能装备研究院有限公司

A hexagon socket screw fastener

The invention relates to the field of fasteners, specifically a hexagon socket screw fastener, including a disassembly mechanism, a connection mechanism, a guide column, a lubrication mechanism, a protection mechanism, a waterproof mechanism, a pushing mechanism and an oiling mechanism; the interior of the lead screw A push mechanism is installed. When the fixing hole of the plate is too large to affect the stability of the fixation, pass the screw through the plate to realize the contact between the pressure plate and the plate. When the two connecting plates are opened, push the push rod towards the direction of the rubber bowl. The rubber bowl is lifted up to realize the lubricating oil inside the rubber bowl flowing out to lubricate the screw, which is convenient for installation. When the lubricating oil inside the rubber bowl flows out, it can flow from the oil inlet on the side wall of the screw to the inside of the oil storage chamber, and loosen it during disassembly The nut is separated from the plate by pressing the pressure plate, and the angle between the two connecting plates becomes smaller, the push rod moves towards the fixed block, the rubber bowl resets, and the pressure rod squeezes the oil received from the inside of the oil storage chamber. Out to the side wall of the screw for lubrication, easy to remove the nut.

Owner:山东九佳紧固件股份有限公司

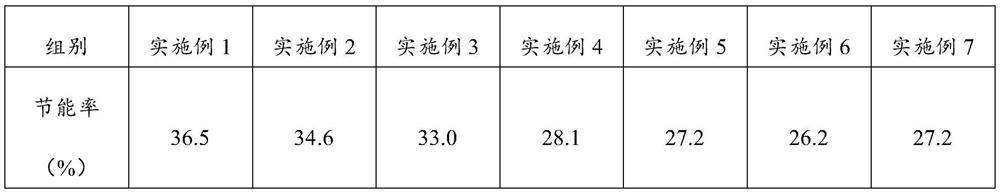

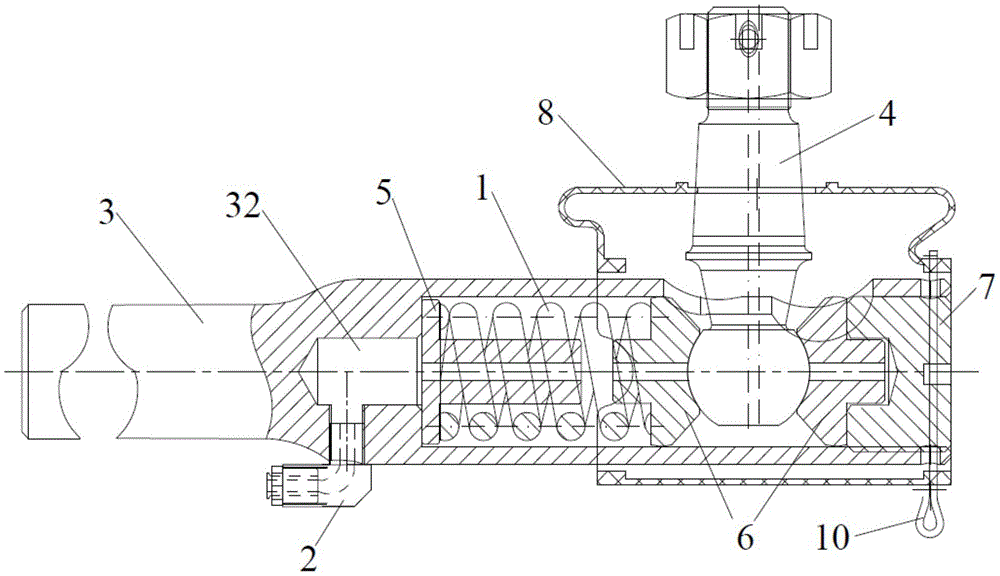

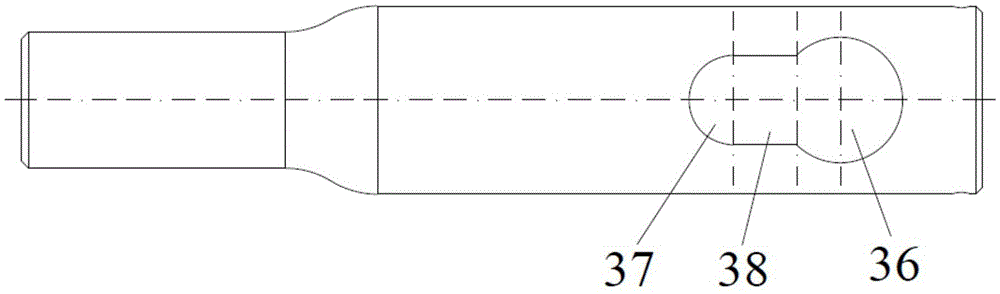

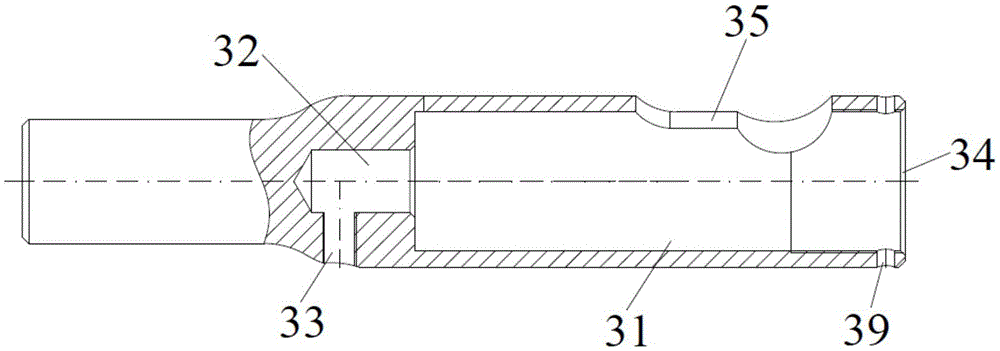

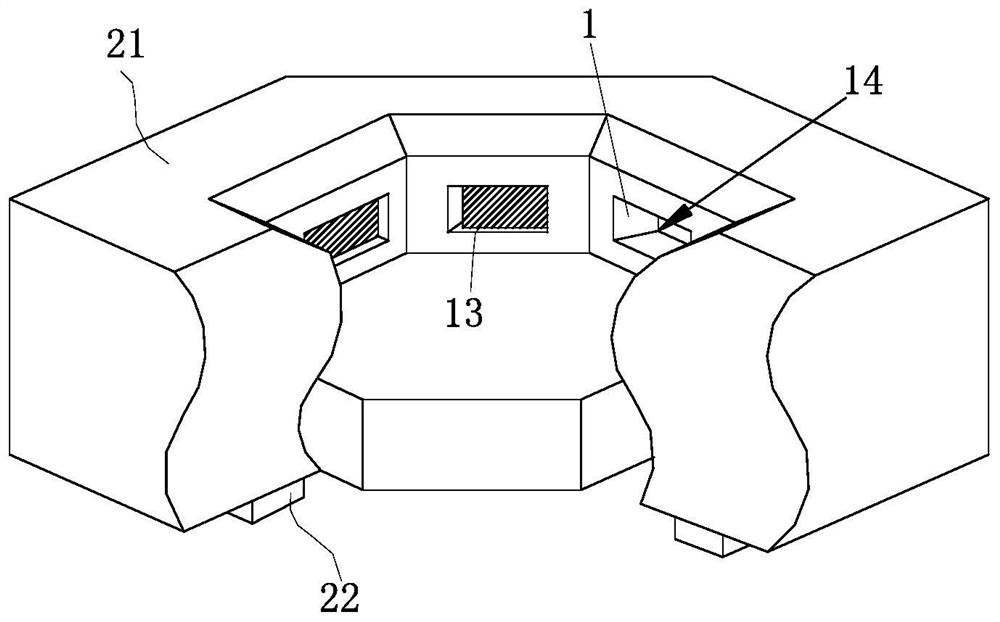

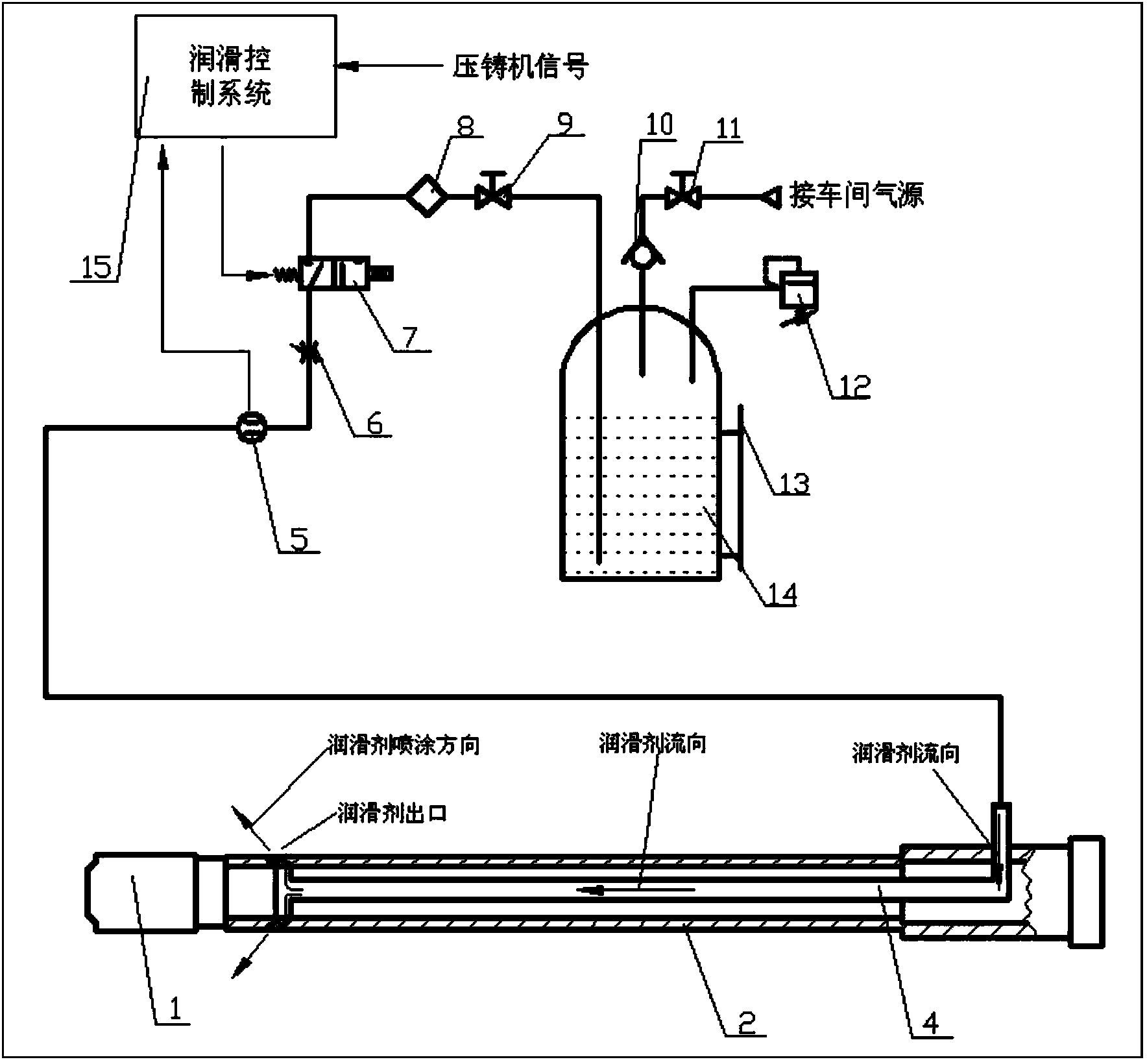

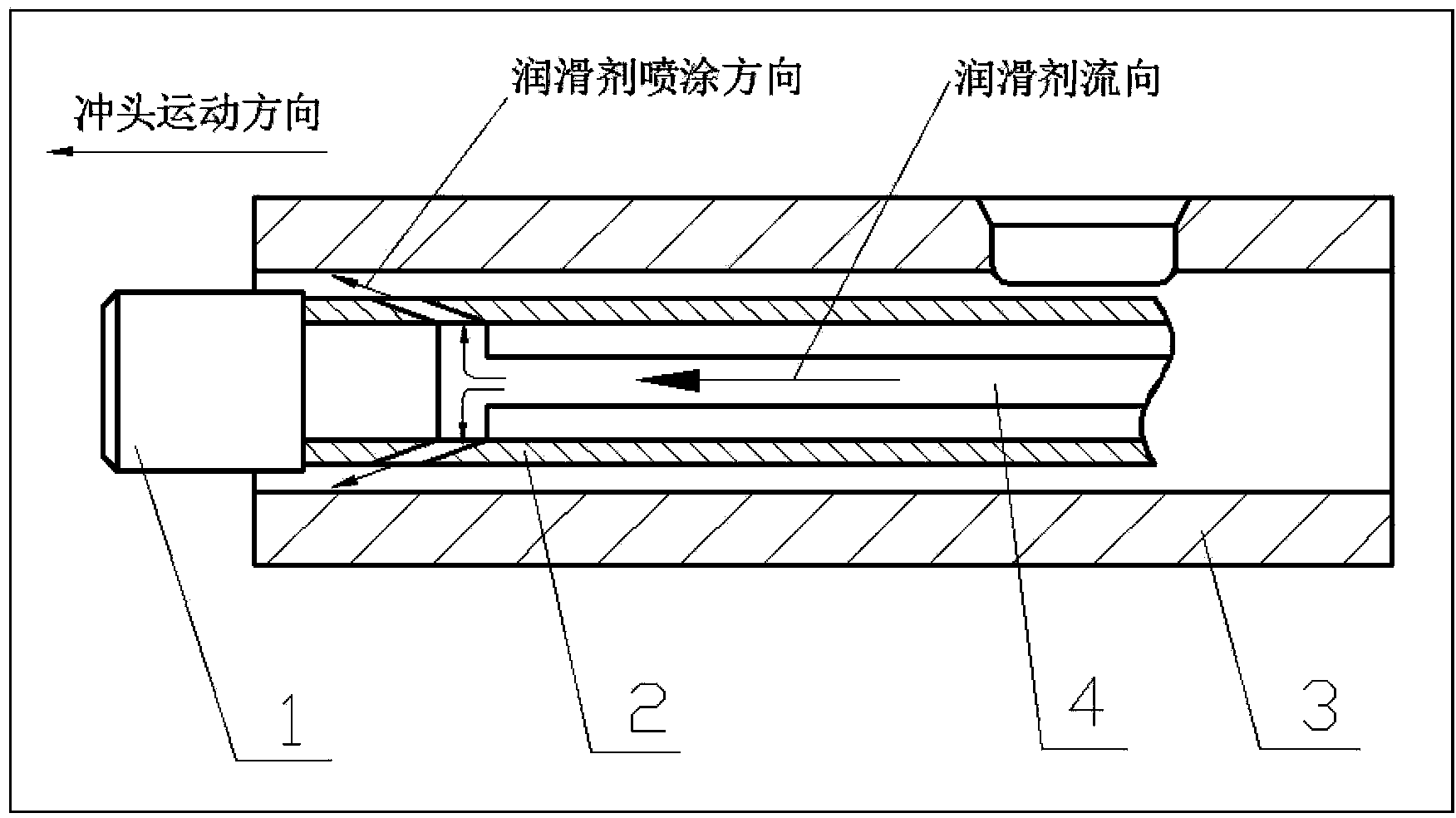

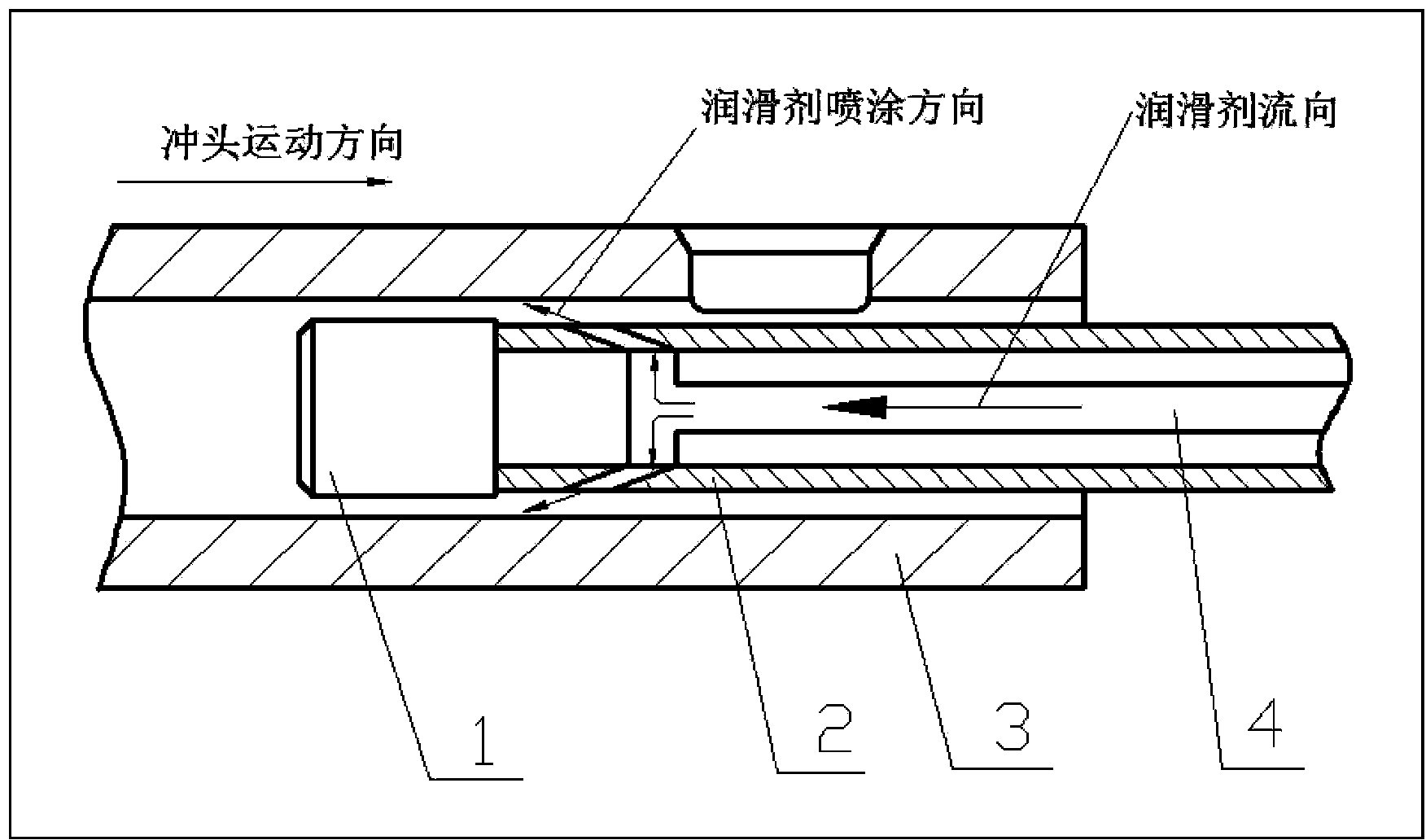

Pressure chamber lubrication method and device of die-casting machine

The invention discloses a pressure chamber lubrication method and a device of a die-casting machine. The pressure chamber lubrication method and the device of the die-casting machine comprise a punch, a plunger rod, a pressure chamber, a lubricant conveying pipeline, a flow meter, a throttle valve, a magnetic valve, a filter, a first manual stop valve, a one-way valve, a second manual stop valve, a safety valve, a liquid level meter, a liquid storage tank and a lubrication control system. The liquid storage tank is connected with the first manual stop valve and is used for storing lubricants, the first manual stop valve is used for stopping conveying of the lubricants in an emergency, the magnetic valve is connected with the filter and used for controlling on-off states of spraying of the lubricants, the magnetic valve, the throttle valve and the flow meter are sequentially connected, the throttle valve and the flow meter are respectively used for adjusting and displaying the flow of the lubricants, the lubricant conveying pipeline is arranged in the plunger rod and is connected with the flow meter, and an input end of the lubrication control system is connected with the die-casting machine and used for receiving plunger rod outgoing signals and plunger rod return signals of the die-casting machine. The pressure chamber lubrication method and the device of the die-casting machine can solve the problem of insufficient lubrication in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

Telescopic arm lubricating and oil accumulation preventing device

InactiveCN112576916AAvoid accumulationComprehensive lubricationConduits/junctionsLubrication check valvesOil canEngineering

The invention relates to the technical field of telescopic arms, and discloses a telescopic arm lubricating and oil accumulation preventing device. The device comprises an outer arm, a protruding block is fixedly installed on the inner wall of the outer arm, an inner arm is slidably connected into the outer arm, an ejector block is slidably connected to the surface of the inner arm, a dielectric substance is fixedly installed at the front end of the ejector block, an ejector rod is fixedly installed outside the ejector block, electrode plates are fixedly installed on the left side and the right side of the ejector rod, an electromagnet is fixedly installed at the end, away from the outer arm, of the ejector rod, and spring rods are fixedly installed on the left side and the right side of the end, away from the outer arm, of the ejector rod. According to the telescopic arm lubricating and oil accumulation preventing device, when the telescopic arm works, atomized oil is automatically sprayed to the interior of the telescopic arm, the spraying area is wide, spraying is uniform, when too much oil is accumulated in the telescopic arm, the internal oil is sucked into an oil cavity to complete circulation, the lubricating oil can be repeatedly used, and resources are greatly saved.

Owner:刘西勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com