Conveniently-fixed self-aligning roller bearing for roller of belt conveyor

A self-aligning roller bearing and belt conveyor technology, applied in conveyor objects, rolling contact bearings, shafts and bearings, etc., can solve the problems of roller bearing lubricating oil inconvenient, inconvenient for workers to install, and throwing out lubricating oil. , to facilitate the operation of workers, improve the lubrication effect, and increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

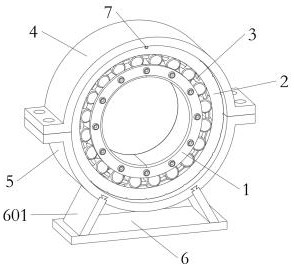

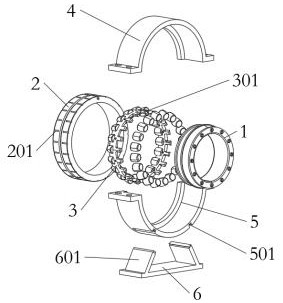

[0026] like Figure 1 to Figure 9 As shown, the present invention provides an easy-to-fix spherical roller bearing for a belt conveyor roller, including a bearing inner ring 1;

Two sets of arc-shaped grooves are symmetrically opened on the outer end face of the bearing inner ring 1, and friction blocks 101 are evenly installed on the inner and outer end faces of the bearing inner ring 1;

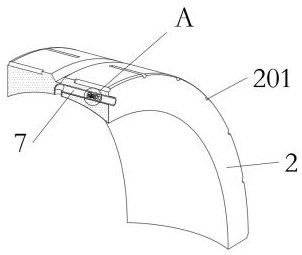

Bearing outer ring 2, there is a groove in the middle of the outer end face of bearing outer ring 2, the groove is a T-shaped structure, and the bearing outer ring 2 is sleeved outside the bearing inner ring 1;

The support frame 3, the two ends of the support frame 3 are evenly provided with card grooves, the two ends of the card groove are arc-shaped structures, the balls are clamped inside the card grooves, and the support frame 3 is located between the bearing inner ring 1 and the bearing outer ring 2;

The first fixing frame 4, the main body of the first fixing frame 4 is a semi-circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com