Hinges for hinge blowout preventer

A blowout preventer and hinge technology, used in wellbore/well components, earthwork drilling, sealing/packaging, etc., can solve the problems of large friction resistance of hinges, heavy weight of side doors, and heavy bearing loads of hinges, and reduce the size of side doors. The effect of switching torque, reducing installation time, and facilitating installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

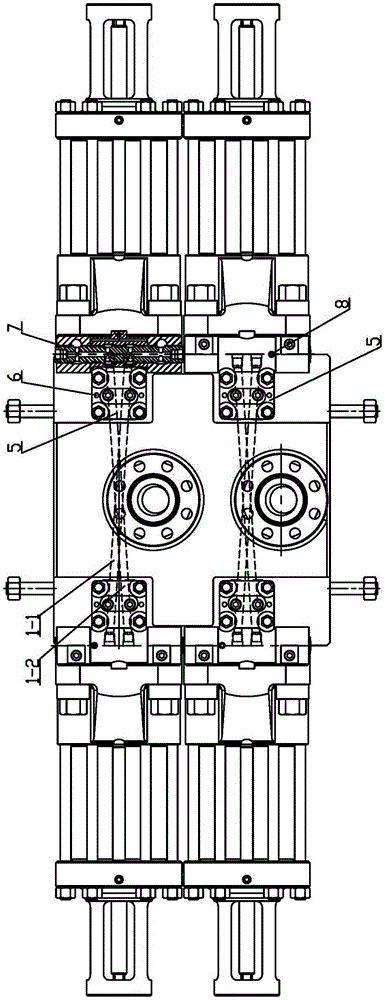

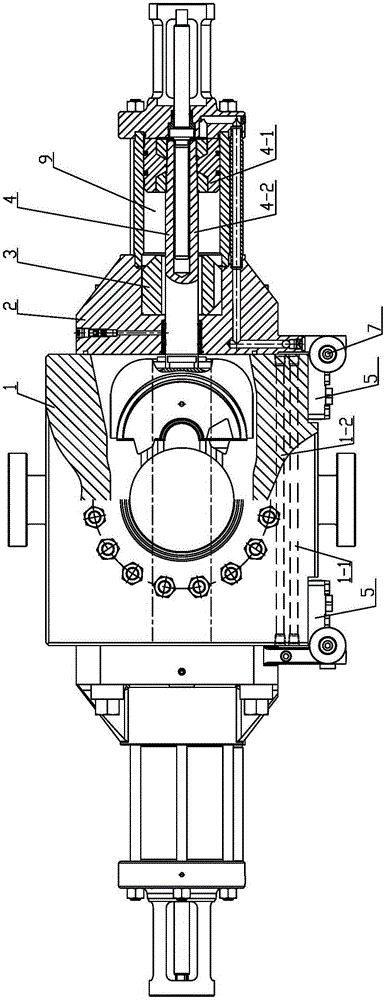

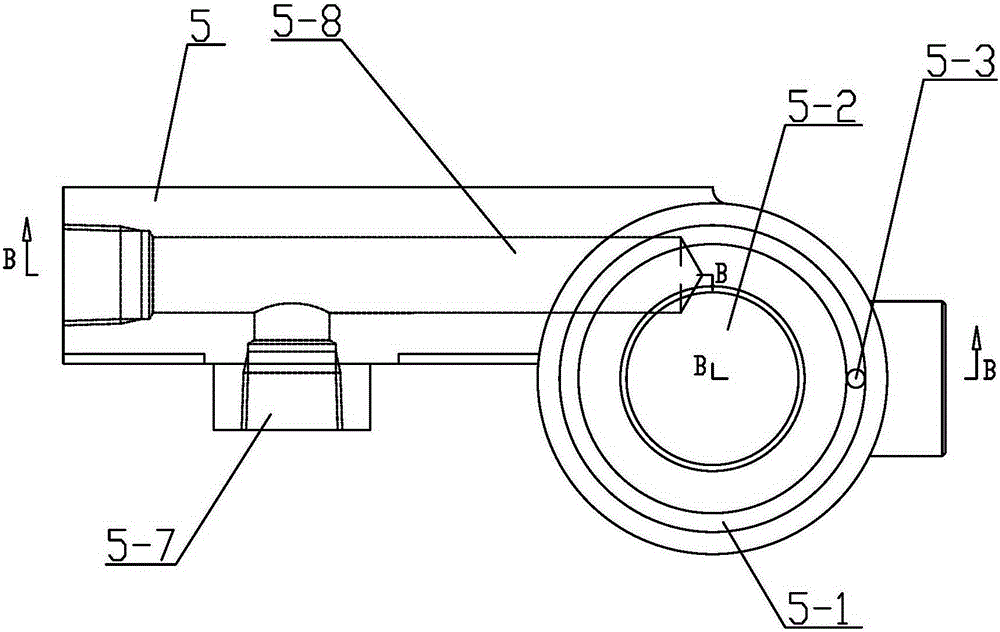

[0026] combine figure 1 and figure 2 As shown, a hinge BOP with an external lubrication device includes a housing 1, a side door 2, a positioning ring 3, a piston assembly 4, a hinge 5, a positioning pin 6, a hinge shaft 7, a set screw 8, and a hydraulic cylinder 9.

[0027] The side door 2 is arranged at one end of the housing 1, and the side door 2 and the housing 1 are fixed by bolt connection, such as figure 1 The length direction CD is shown to one end. The hinge 5 is arranged on one side of the housing 1 in the width direction MD, the hinge 5 and the housing 1 are fixed by bolts, and the positioning pin 6 is inserted into the positioning hole of the housing 1 through the positioning hole on the hinge 5 . There are 4 hinges in total, one row is arranged on the upper and lower sides, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com