Improving method and structure of water release gate submerged orifice plane emergency gate

A technology of accident gate and sluice gate, which is applied in hydraulic engineering, marine engineering, coastline protection, etc., can solve problems such as poor hydraulic conditions, large thickness of parapet and gate, and cavitation, so as to ensure water-stop effect and structural safety. The effect of saving metal structure investment and saving civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

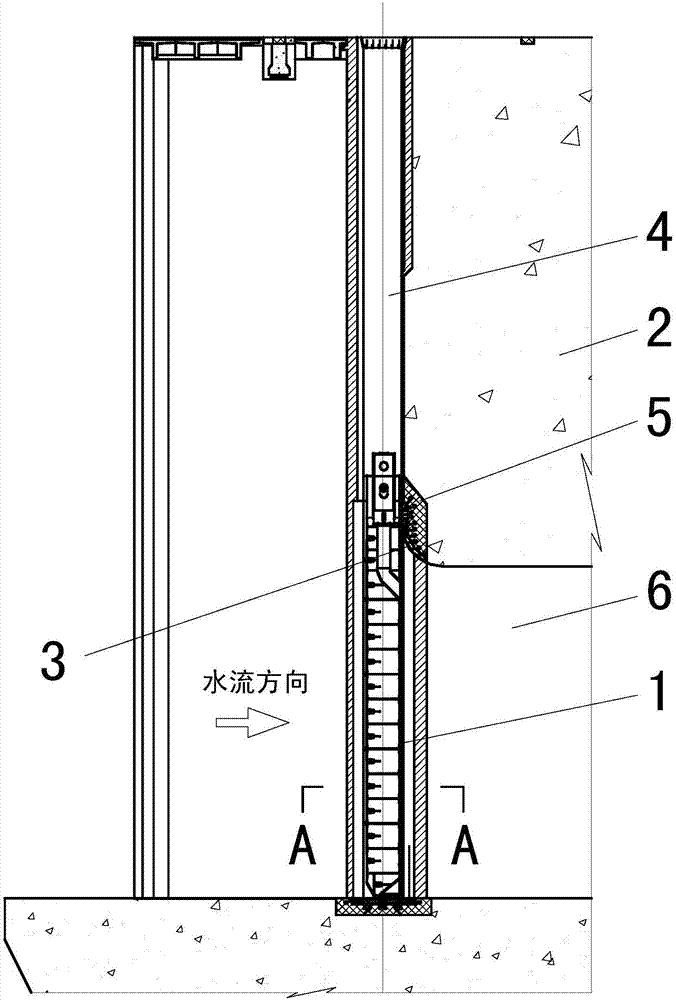

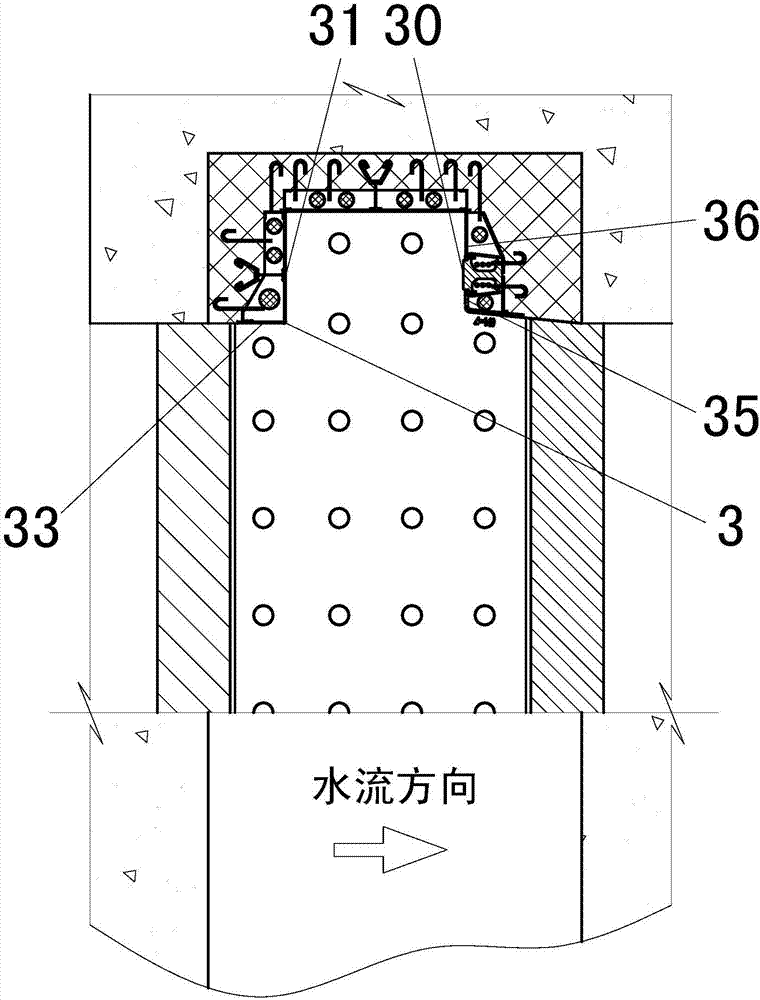

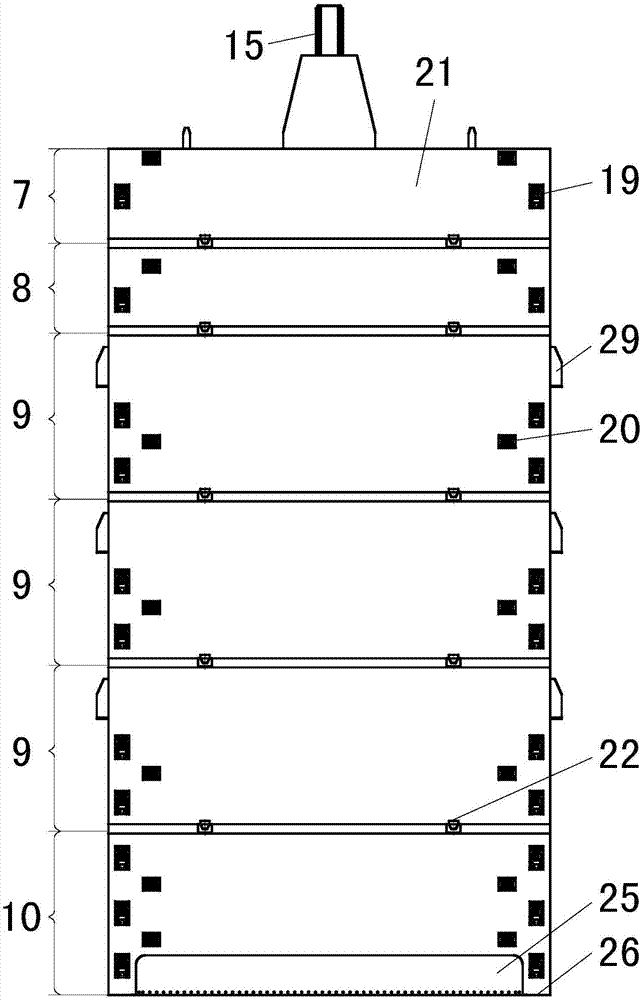

[0036] The submersible plane emergency gate of the discharge sluice in this example is set in front of the parapet 2, the lower edge of the parapet 2 is a bell mouth formed by the transition of the arc 3, the upstream of the plane emergency gate 1 is open, and the gate slot 4 of the plane emergency gate 1 It is an open upstream type II door slot, and the lintel 5 is arranged at the transition position of the arc 3 of the parapet 2 . The plane emergency gate 1 is formed by welding the top section door leaf 7, the second top section door leaf 8, the middle section door leaf 9 and the bottom section door leaf 10 to form an integral structure; the panel 21 of the plane emergency gate 1 is arranged on the upstream side, and the top water seal 11 and the side water seal 12 are arranged on the downstream side, and the bottom water seal 13 is arranged on the upstream side and the left and right sides along the water flow direction and is connected with the side water seal 12 .

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com