Automotive differential planetary gear gasket with multiple pits and multiple oil grooves

A technology for planetary gears and differentials, applied in differential transmissions, gear lubrication/cooling, belts/chains/gears, etc., can solve problems such as mechanical wear, short-term effect, and no supplementary lubricating oil, etc., to achieve improvement Effects of lubrication conditions, increased safety performance, and reduced structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

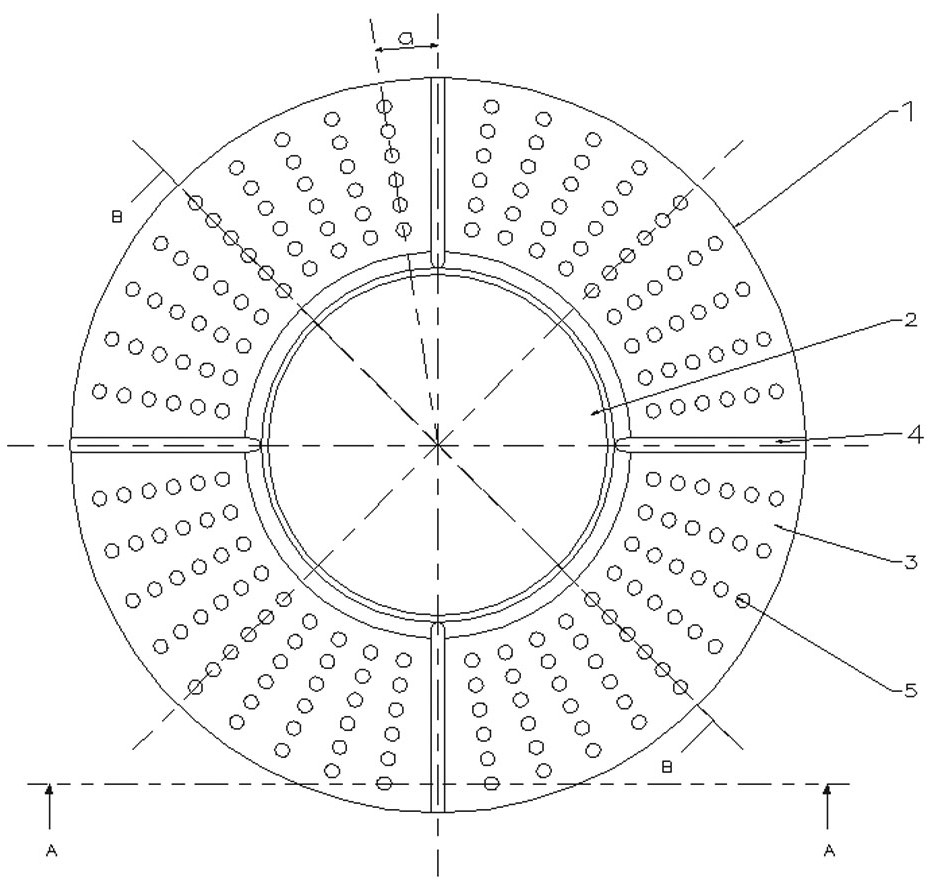

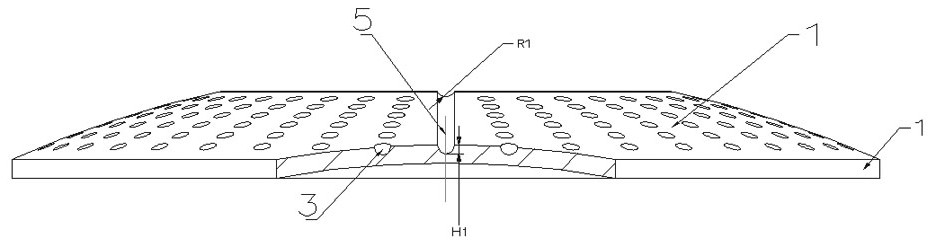

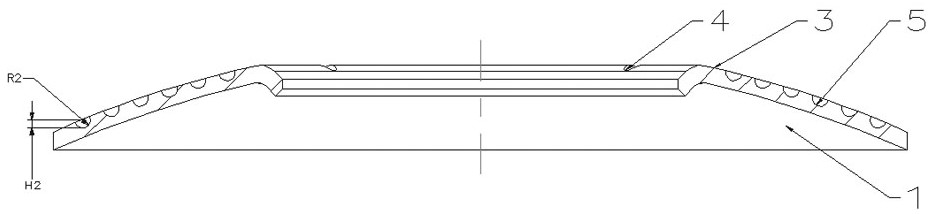

[0016] figure 1 The vehicle differential planetary gear gasket with multiple pits and multiple oil grooves is shown. It uses the gasket body 1 as the carrier. The disc-shaped gasket body 1 is provided with a coaxial circular inner hole 2 in the middle, facing upward One side is the convex spherical surface 3, the structural feature of the present invention is reflected in the uniform distribution of pits 5 on the convex spherical surface 3 of the gasket body 1, and four radial oil grooves 4 alternate to form four fan-shaped pit groups. The oil groove 4 is a linear concave circular arc groove, the concave radius R1 of the oil groove 4 is 1.2-1.8 mm, and the concave depth H1 is 1.0-1.6 mm. The four radial oil grooves 4 on the convex spherical surface 3 coincide with the bisectors of the four quadrant angles. One end of the linear oil gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com