Single-screw compressor star wheel-screw meshing pair liquid spraying lubrication structure and design method

A single-screw compressor and meshing pair technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reducing exhaust parameters and not meeting process requirements, and achieve the effect of slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings.

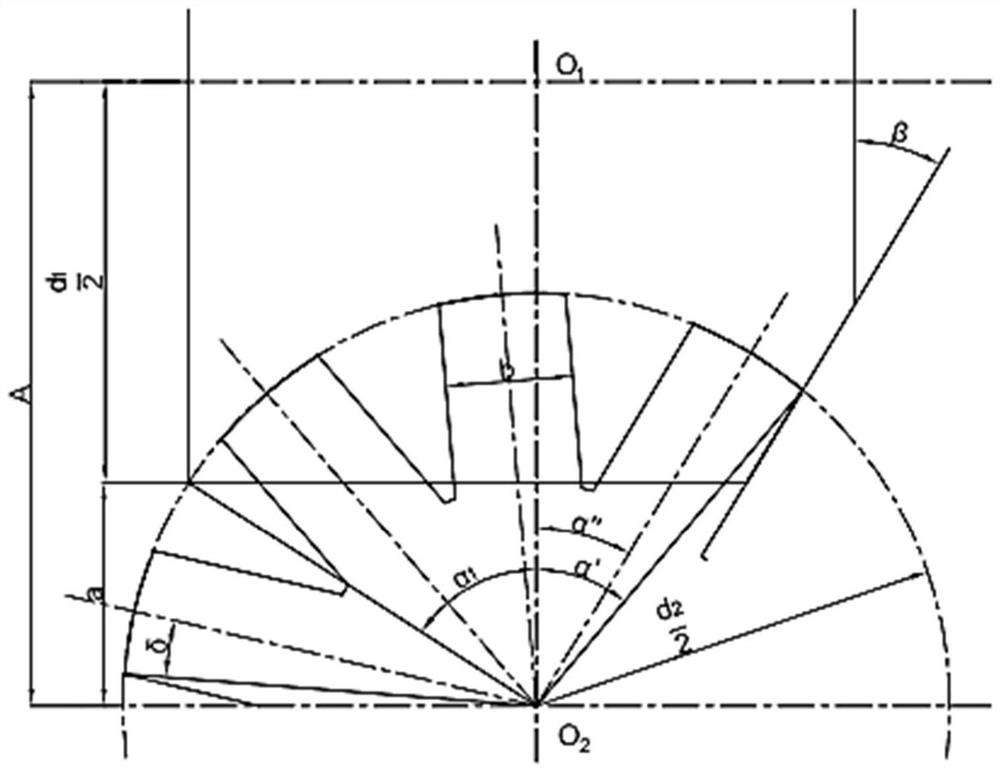

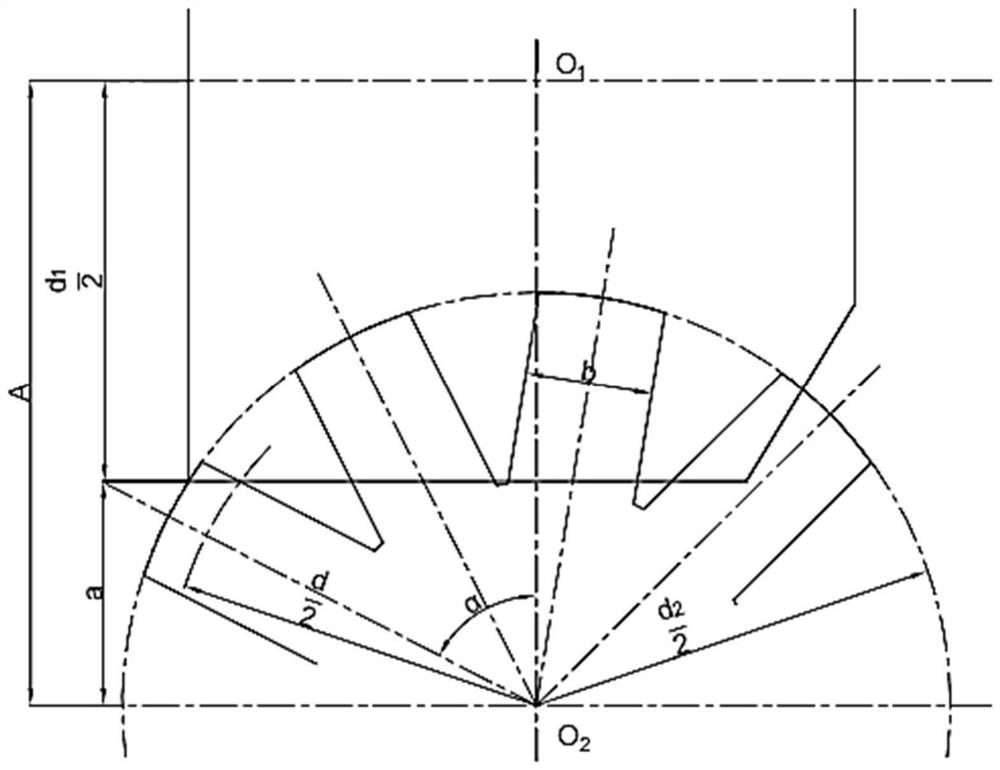

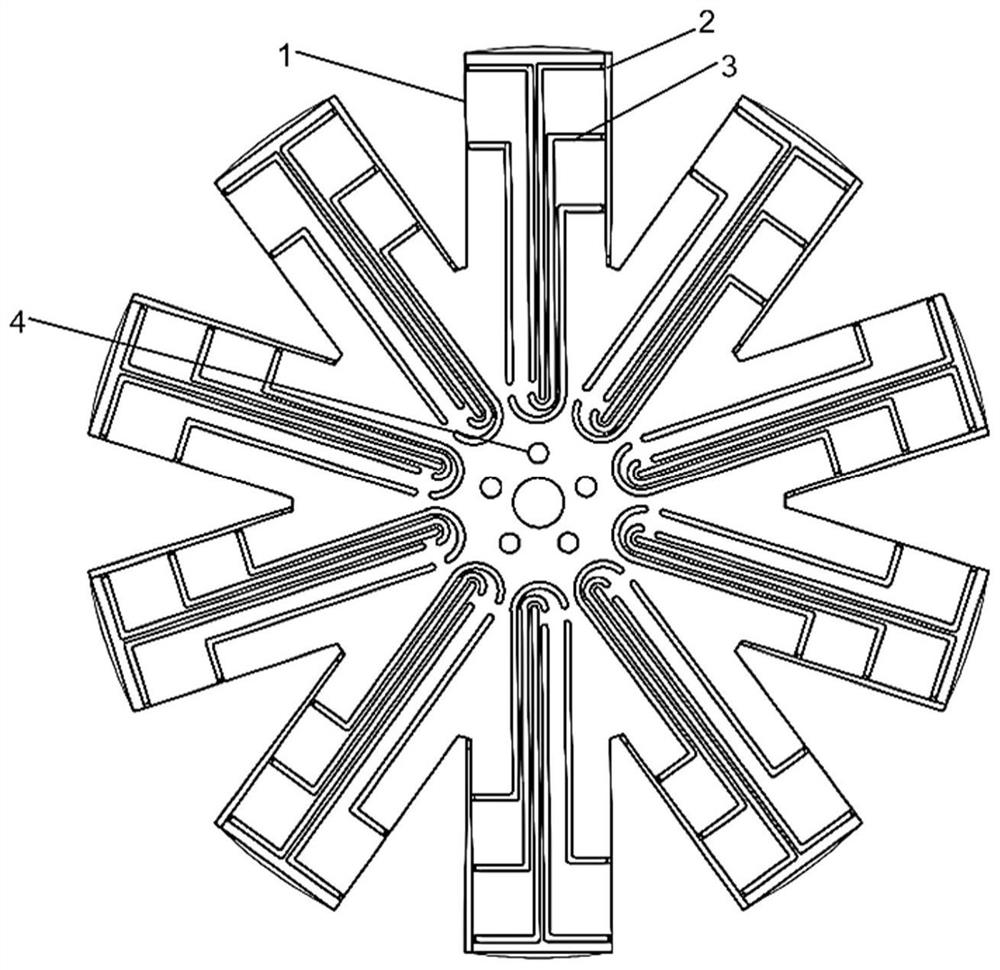

[0038] see image 3 , Figure 4 , a single-screw compressor star wheel-screw meshing pair liquid spray lubrication structure proposed by the present invention, the structure includes a star wheel body with a plurality of channels 3 inside, and the outlet 2 corresponding to each channel 3 is opened in the star wheel At different positions on the side of the gear teeth, the coolant is passed from the inlet 6 corresponding to each channel 3 into the channel 3, and then drained through the channel 3, and finally sprayed into the star wheel from the outlet 2 corresponding to each channel 3- Screw meshing pair. Further, the channels 3 are provided with several groups corresponding to each star gear tooth, and each group of channels 3 includes a plurality of channels 3 extending to different heights on both sides of the star gear teeth. The outlets 2 are opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com