Travelling part of split-cavity structure

A walking part and sub-cavity technology, which is applied in the direction of slitting machinery, transmission device, gear lubrication/cooling, etc., can solve the problems of wear and loss of parts, short life of equipment, etc., to solve serious wear and low life, improve strength, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

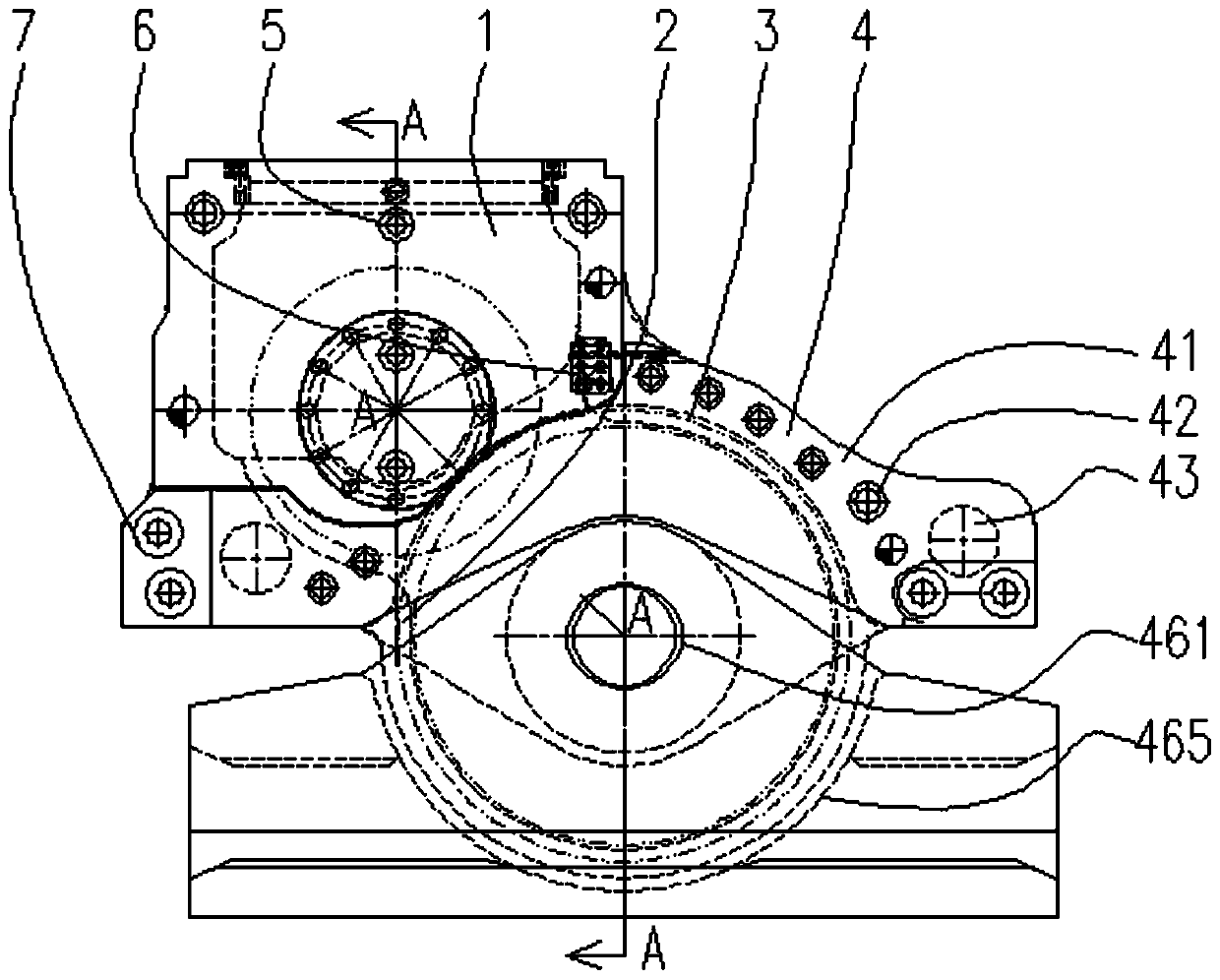

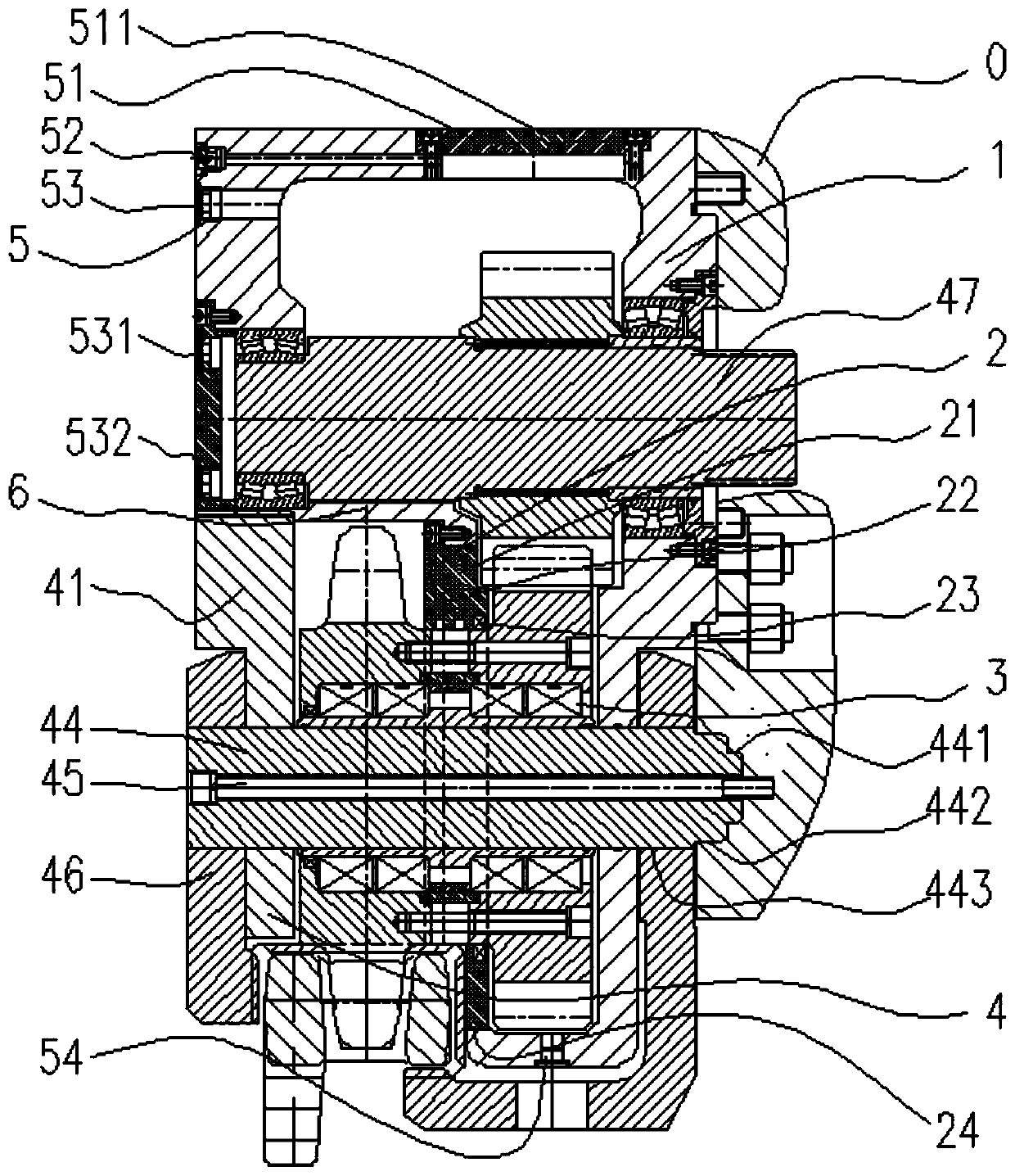

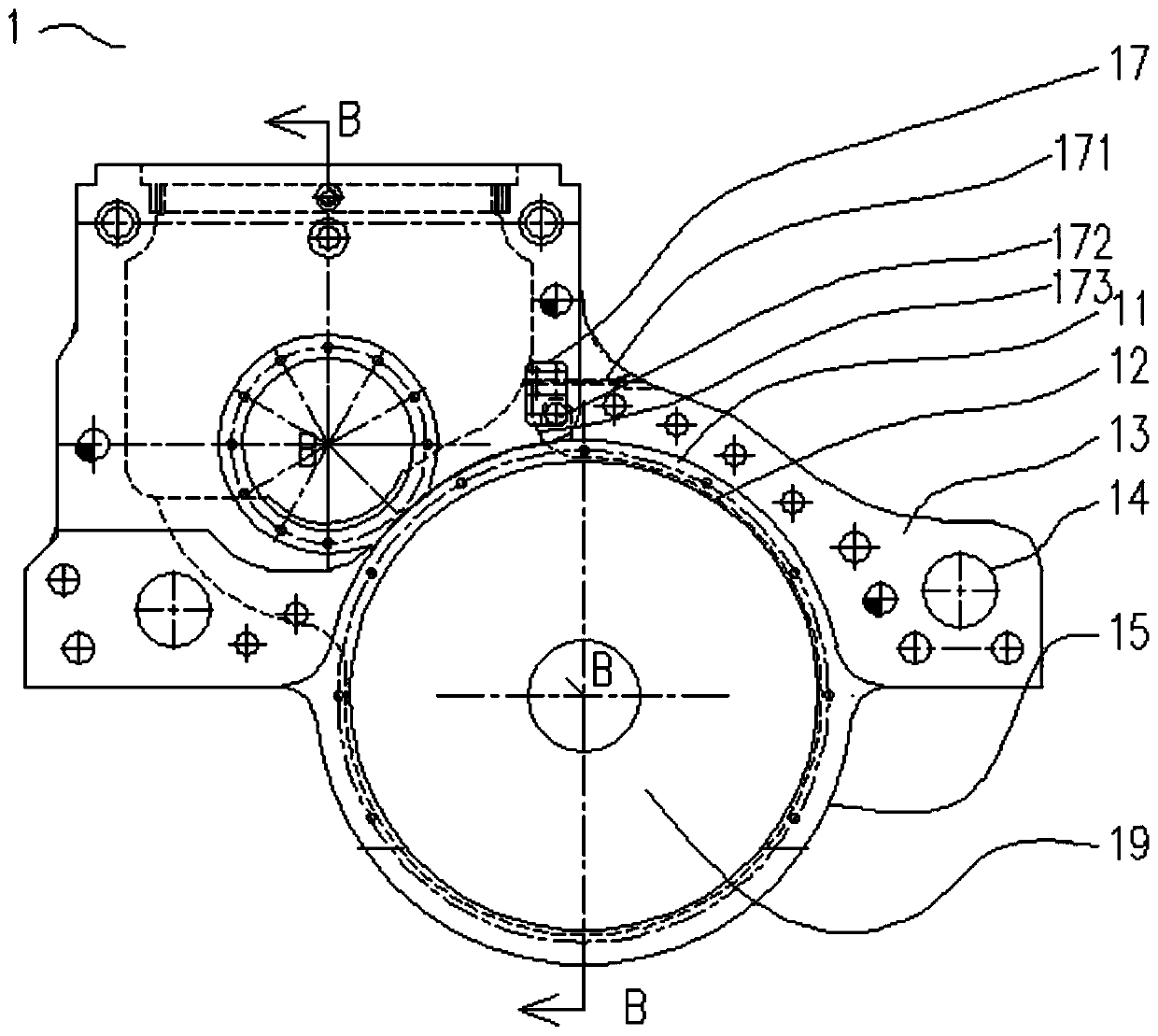

[0040] The invention discloses a walking part with a sub-cavity structure, such as Figure 1-13 As shown, it includes a housing 1 , a drive shaft 471 , a drive gear 473 , a driven gear 36 , a road wheel 37 , a guide shoe 46 and a connecting plate 41 . The housing is provided with an oil pool, the upper part of the connecting plate 41 is detachably fixed on the housing, and the lower part of the connecting plate and the lower front side wall of the oil pool form an open chamber. The drive shaft 471 is supported on the housing through two sets of front and rear bearings 472, and the drive gear is fixedly mounted on the drive shaft. The driving gear 473 is externally meshed with the driven gear 36 . The traveling wheel 37 and the driven gear 36 are coaxially fixed, and one after the other is rotatably connected to the same support shaft 44 via a bearing 39 . The support shaft runs through the connecting ear hole 413 of the connecting plate and the front and rear side walls of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com