Bionic rolling rake based on soil biological characteristics

A technology of soil biology and bionic rake, applied in the field of bionic rolling rake, can solve the problems of abrasive wear resistance, soil adhesion, etc., and achieve the effects of reduced resistance, easy to break soil and remove stubble, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

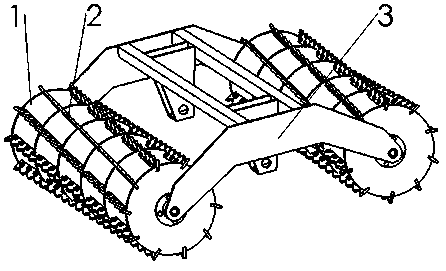

[0034] Example 1: Such as figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 , Figure 5 , Figure 5-1 , Figure 5-2 , Figure 5-3 As shown, a bionic rolling rake based on the biological characteristics of the soil is mainly composed of a rolling basket, a bionic rake blade and a frame. The rolling basket 1 is provided with a bionic rake blade 2, and the bionic rake blade 2 includes a scale structure 4 with bionic ribs. The soil contact surface and the cutting edge of the bionic sawtooth structure 5;

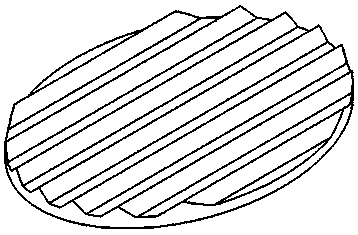

[0035] Further, the scale micro-thorn structure on the soil-contacting surface with the bionic ribbed scale structure 4, the scale shape is an ellipse, and the major axis a and the minor axis b are assigned according to the side plate and the harrow structure of the rolling basket 1. a=7.5 mm, b=5 mm, namely: x 2 / 7.5 2 +y 2 / 5 2 = 1, take the thickness of the scale H=0.5 mm;

[0036] Further, a bionic ribbed structure 6 is distributed on the scales, and the ribbed cross secti...

Embodiment 2

[0039] Example 2: Such as figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 , Image 6 , Figure 6-1 , Figure 6-2 , Figure 6-3 As shown, a bionic rolling rake based on the biological characteristics of the soil is mainly composed of a rolling basket, a bionic rake blade and a frame. The bionic rake blade has a soil contact surface with a bionic ribbed scale structure and a blade with a bionic sawtooth structure;

[0040] Further, the scale micro-thorn structure on the soil-contacting surface with the bionic ribbed scale structure 4, the scale shape is an ellipse, and the major axis a and the minor axis b are assigned according to the side plate and the harrow structure of the rolling basket 1. a=10 mm, b=7.5 mm, namely: x 2 / 10 2 +y 2 / 7.5 2 = 1, take the scale thickness H=1 mm;

[0041] Further, a bionic ribbed structure 6 is distributed on the scales, the cross-section of the ribs is triangular, and the height of the triangle is h=1mm, the rib height is 1 mm, and the rib...

Embodiment 3

[0044] Example 3: Such as figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 , Figure 7 , Figure 7-1 , Figure 7-2 , Figure 7-3 , Figure 7-4 As shown, a bionic rolling rake based on the biological characteristics of the soil is mainly composed of a rolling basket, a bionic rake blade and a frame. The bionic rake blade has a soil contact surface with a bionic ribbed scale structure and a blade with a bionic sawtooth structure;

[0045] Further, the scale micro-thorn structure on the biomimetic soil-contacting surface, the scale shape is an ellipse, the major axis a and the minor axis b are assigned according to the side plate of the rolling basket and the harrow blade structure, taking a=12 mm, b=8 mm, namely: x 2 / 12 2 +y 2 / 8 2 = 1, take the thickness of the scale H=0.5 mm;

[0046] Further, a bionic ribbed structure is distributed on the scales, the ribbed cross section is a quadratic curve, and the quadratic function curve-shaped ribbed cross section has a function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com