Siliceous low-temperature wear-resistant anti-corrosion material

A low-temperature, anti-corrosion technology, applied in the field of wear-resistant materials, can solve problems affecting the safe operation of power plants, and achieve the effects of simple construction, good peeling resistance, and good thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

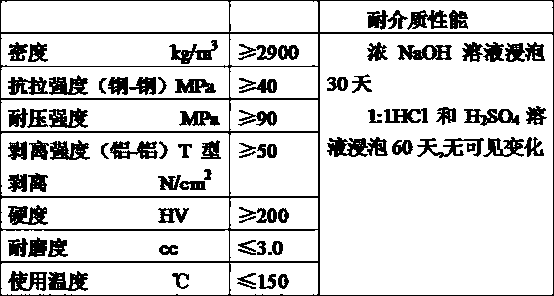

Image

Examples

Embodiment 1

[0014] A siliceous low-temperature wear-resistant and anti-corrosion material, which is made by double-modifying an organic adhesive and a curing agent for temperature resistance, and adding a high-hardness filler. The formula is as follows: 40 parts of organic adhesive, curing 35 parts of agent, 25 parts of high hardness filler.

[0015] Specifically, the organic adhesive includes urea-formaldehyde resin glue, acetone, acrylate latex powder, epoxy resin and organic silane coupling agent.

[0016] Specifically, the urea-formaldehyde resin glue, acetone, acrylate latex powder, epoxy resin and organosilane coupling agent are mixed according to the mass ratio of 2:1:2:3:2.

[0017] Specifically, the curing agent includes phosphoric acid, aluminum hydroxide, sodium silicide, sodium fluorosilicate, potassium fluorosilicate and Portland cement.

[0018] Specifically, the phosphoric acid, aluminum hydroxide, sodium silicide, sodium fluorosilicate, potassium fluorosilicate and Portla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com