Coordinated installation method of drive shaft in road-construction mechanical transmission system

A technology of transmission system and road construction machinery, which is applied in the field of coordinated installation of transmission shafts in the transmission system of road construction machinery, which can solve problems such as poor coordination, wear of transmission shafts, and short service life of transmission systems, and achieve high installation efficiency and installation accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

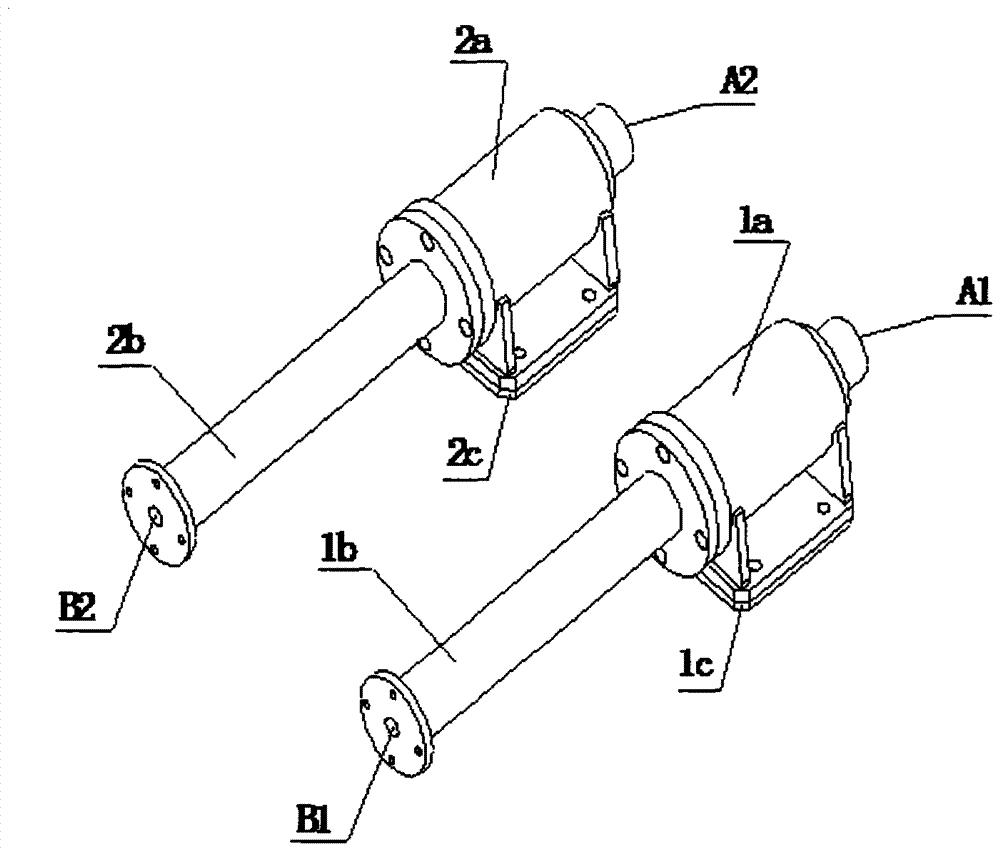

[0040] A double-shaft transmission system needs to be added to the box body of road construction machinery to realize the movement of the box body forward or backward along the horizontal direction. The first transmission system and the second transmission system of the newly added biaxial transmission system are respectively installed on the left and right sides of the bottom beam of the road construction mechanical equipment. The bottom beam width dimension of road building mechanical equipment is 1600 millimeters, and the length dimension of box body is 3000 millimeters, and the width dimension of box body is 1600 millimeters.

[0041] Apply laser tracker (Leica tracker, manufacturer: Hexagon Measurement Technology (Qingdao) Co., Ltd.) in combination with the front and rear ends of the drive shaft in the auxiliary drive system to increase the position of the cursor hole and the drive system to increase the adjustment gasket, adopt optical installation method to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com