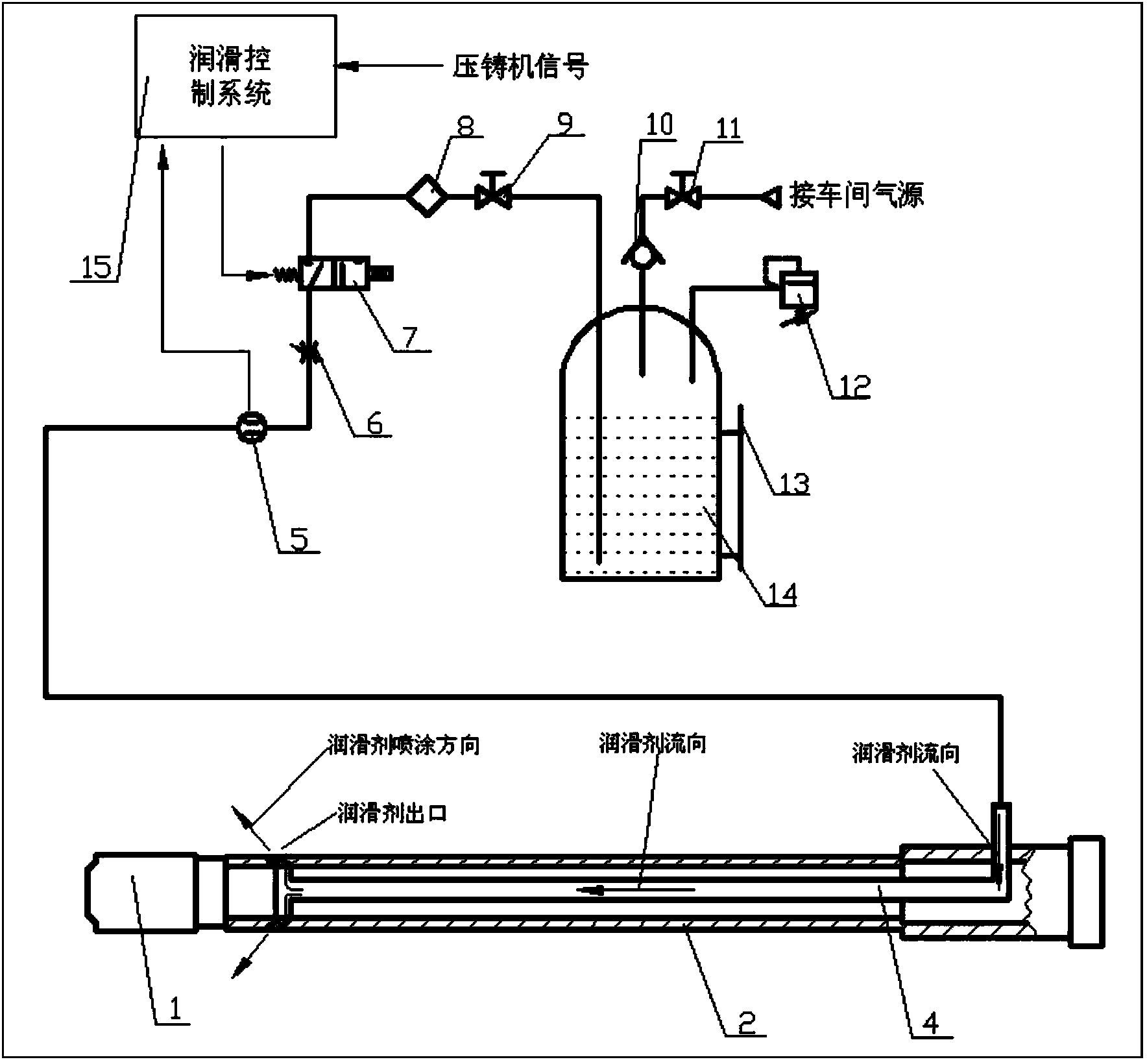

Pressure chamber lubrication method and device of die-casting machine

A lubricating device and die-casting machine technology, applied in the field of casting, can solve problems such as insufficient lubrication, and achieve the effects of comprehensive lubrication, improved production efficiency, and good flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

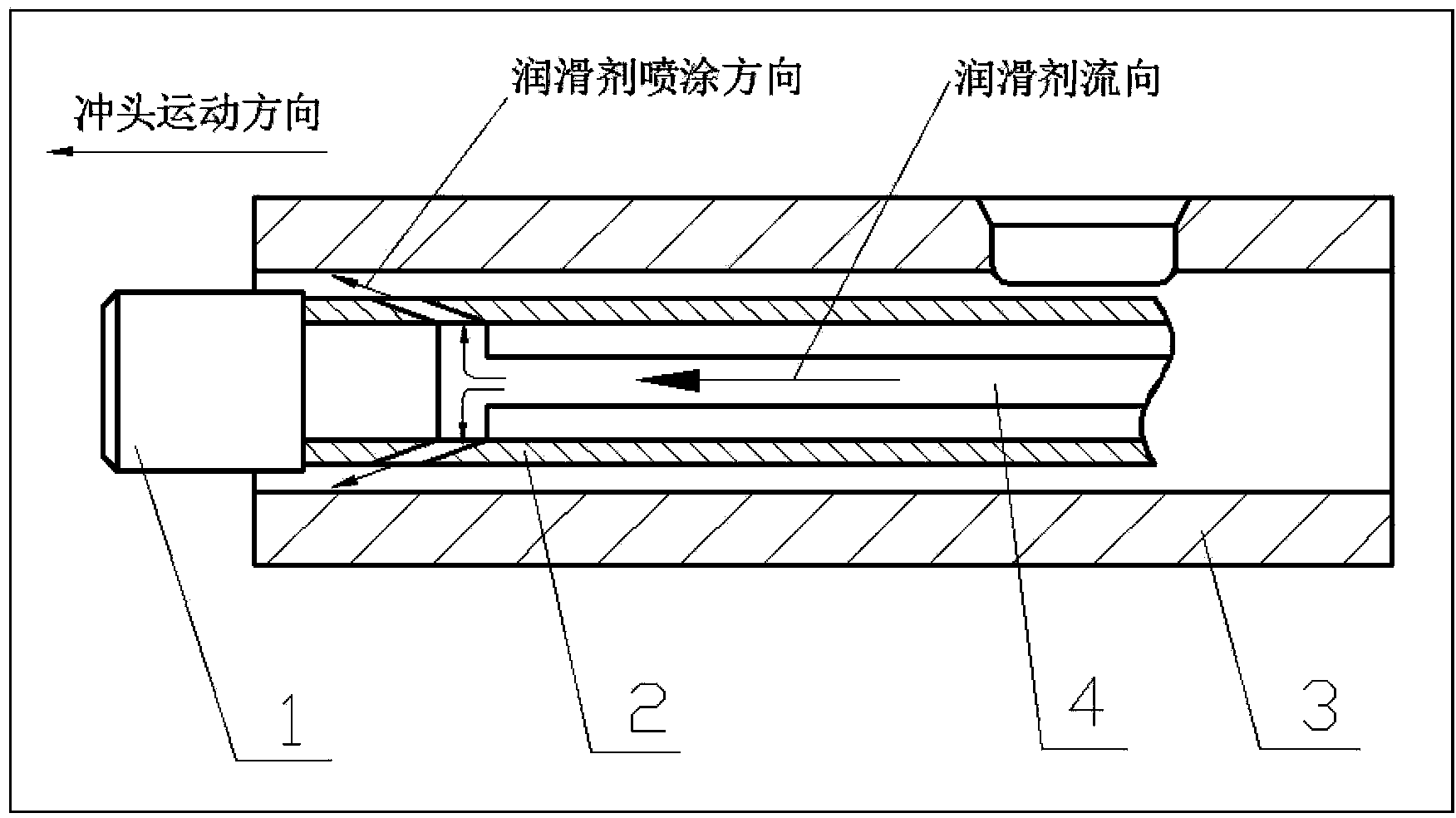

Embodiment 1

[0052] According to the lubricating method in the pressure chamber and related devices of the present invention, the ZL101 alloy is die-cast on a 2800KN horizontal cold chamber die-casting machine. The pressure inner diameter of the die-casting machine is 50 mm, the length of the punch is 80 mm, and the lubricant outlet is 6 oblique holes with a diameter of 3 mm. Before die-casting, install the lubricating device according to the instructions, and adjust the throttle valve to make the flow of lubricant meet the process requirements. The pouring temperature of die-casting is 670°C, the slow injection speed is 0.25m / s, the high speed is 3m / s, and the injection specific pressure is 70Mpa. Under the above process conditions, the pressure chamber and the punch are lubricated by the method of lubricating the pressure chamber, and the die-casting water-based paint is used as the lubricant. When the shoot rod is retracted, the lubricating device can accurately spray the lubricant on ...

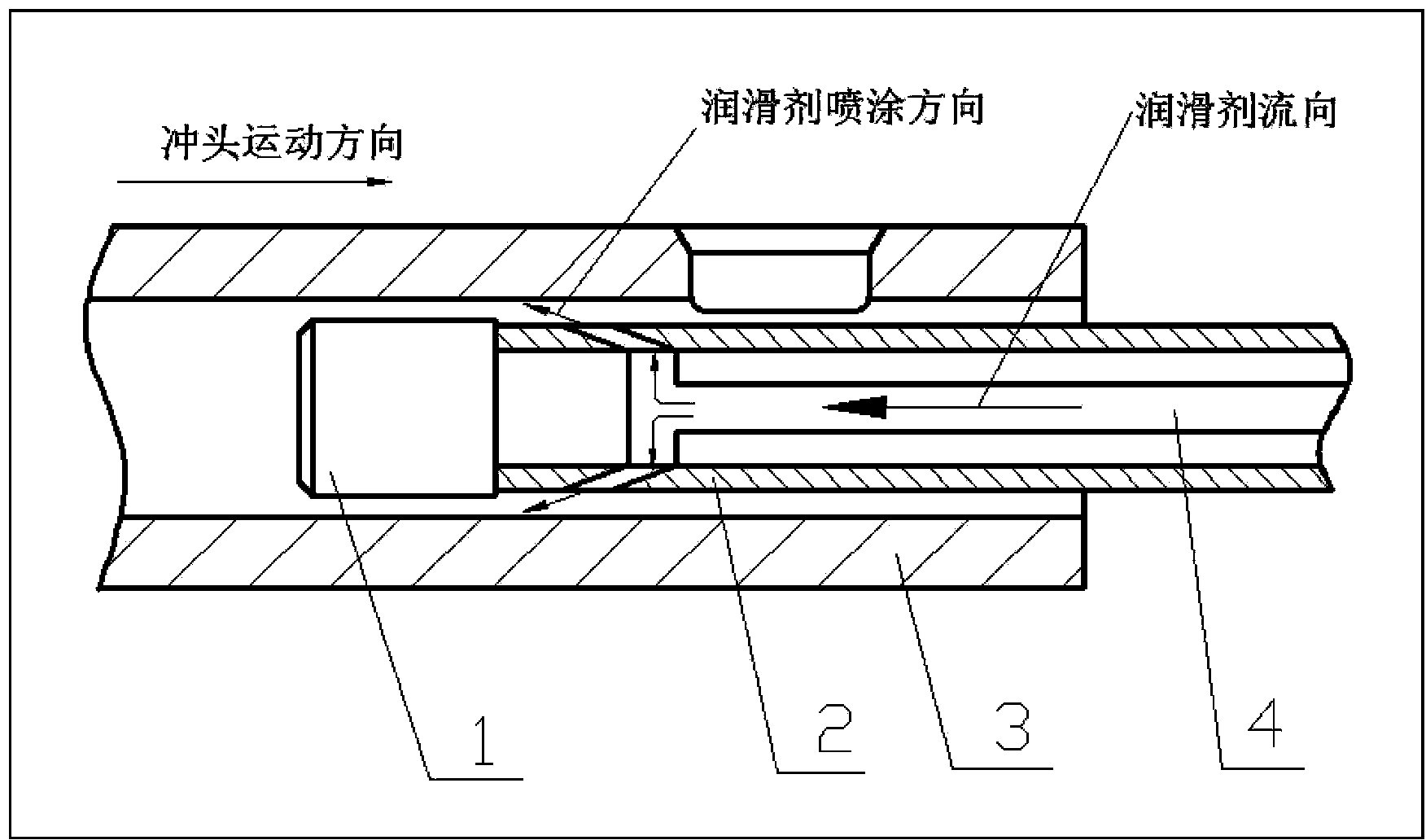

Embodiment 2

[0055] Die-casting is carried out on a 16000KN horizontal cold-chamber die-casting machine using this pressure chamber lubrication method. The diameter of the pressure chamber is 110mm, and the lubricant outlet is 6 oblique holes with a diameter of 5mm. ZL104 alloy is used for die-casting. The pouring temperature is 670°C and slow injection. The speed is 0.25m / s, the high speed is 3m / s, and the injection specific pressure is 70Mpa. Adjust the throttle valve to make the lubricant flow appropriate. The lubricant sprayed on the surface of the pressure chamber can dry quickly to form a lubricating layer. After multiple die-casting cycles on the machine, the lubrication between the pressure chamber and the punch is good, and the punch has no abnormal wear. The lubricating layer is under the action of the molten metal. No smoke was produced. Therefore, the amount of gas generated by the lubricant is very small, and it does not pollute the molten metal and the environment on site. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com