Low-foam green CIP bactericidal concentrated cleaning agent

A concentrated cleaning agent, cleaning agent technology, applied in detergent compositions, detergent compounding agents, surface active detergent compositions, etc., can solve the problem of non-compliance with green cleaning standards, industrial waste water environmental pollution, and long cleaning process time. and other problems, to achieve the effect of good resistance to hard water and decontamination, saving purchase costs and saving equipment purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

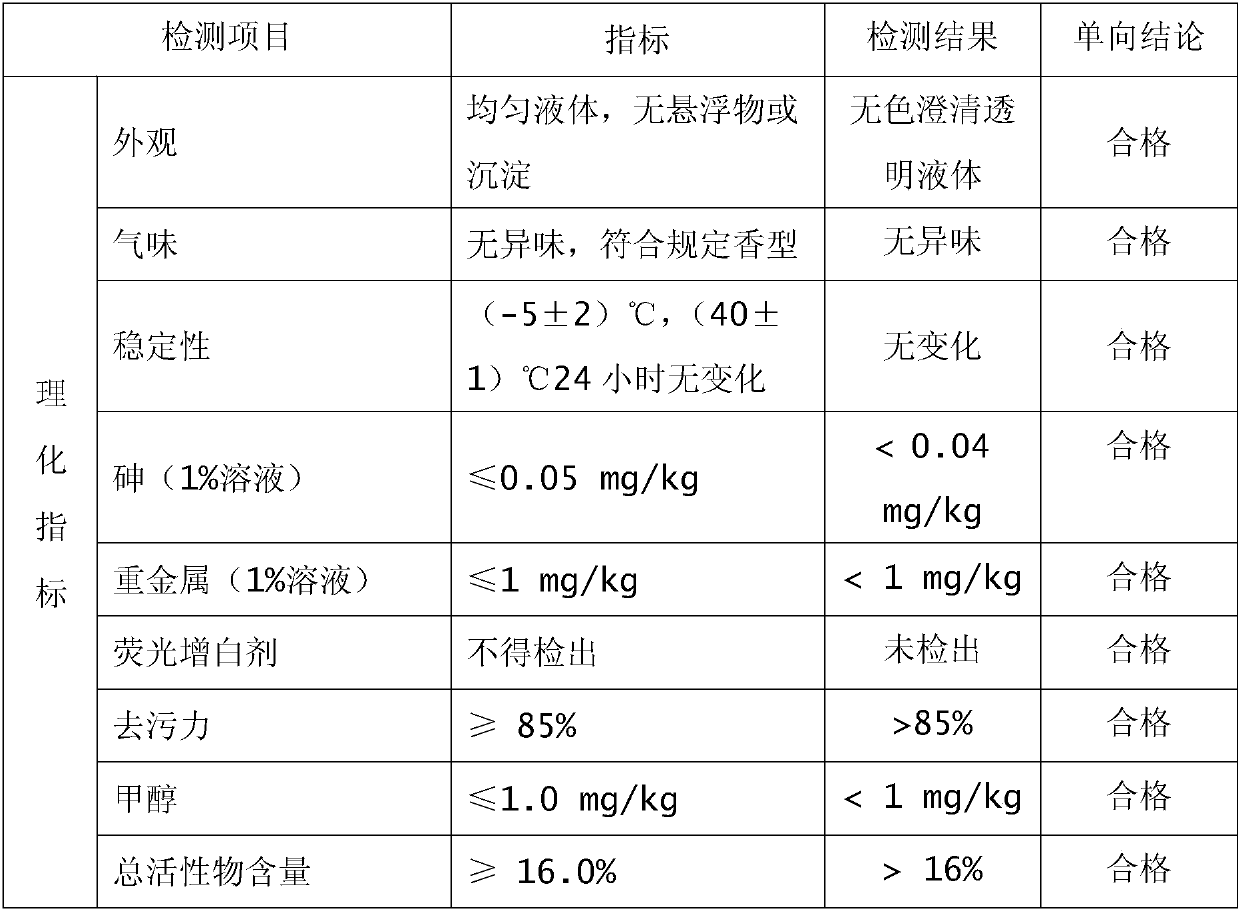

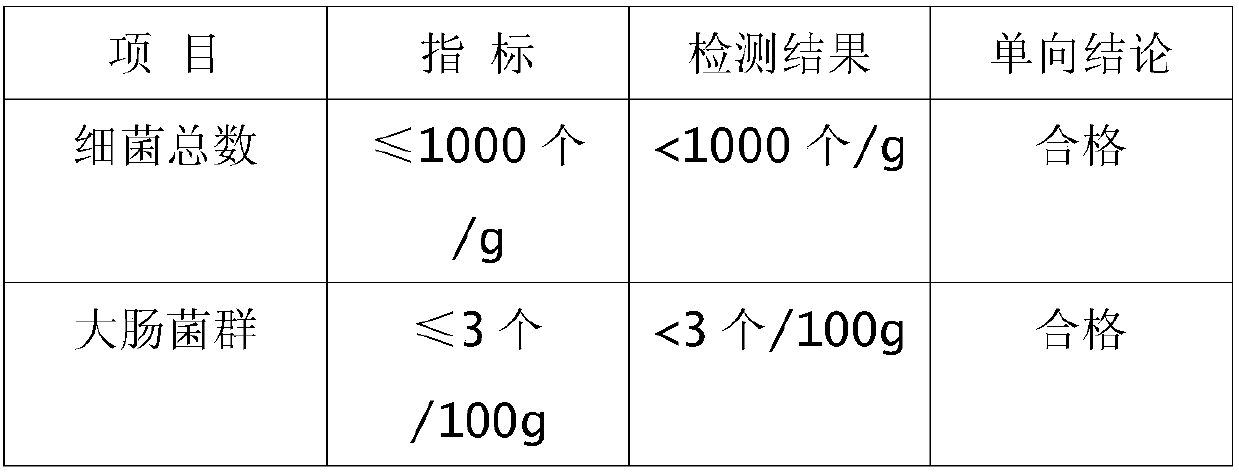

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: a kind of low-foaming green CIP sterilizing concentrated cleaning agent of this embodiment is made up of 1~5% alkyl glucoside, 1~12% fatty acid methyl ester ethoxylate, 0~6% modified grease by weight percentage Ethoxylate, 0-8% modified oil ethoxylate sulfonate, 0-3% coconut oil fatty acid diethanolamide 6501, 0.5-2.0% undecyl imidazoline amphoteric surfactant, 1-5 % additives, 1-6% chelating agent, 0-2% penetrating agent, 0.1-0.4% defoamer, 0.1-0.3% bactericide, 0.05-0.15% pH regulator and the balance of deionized water.

[0015] Coconut oil fatty acid diethanolamide 6501, easily soluble in water, has good foaming, foam stabilization, penetration and decontamination, anti-hard water and other functions. no danger.

[0016] Undecyl imidazoline amphoteric surfactant (1-carboxymethyloxyethyl-1-carboxymethyl-2-alkylimidazoline sodium salt) is less irritating to eyes and skin and has good foaming properties . no danger.

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the alkyl glycoside is C 08- 10 APG or C 12-14 APG. Others are the same as in the first embodiment.

[0018] Alkyl glucoside, referred to as APG, is a green surfactant synthesized by fatty alcohol and glucose under catalyst conditions. It has high permeability, alkali resistance, and good ecological safety. Purchased from Shanghai Fakai Chemical Co., Ltd.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the fatty acid methyl ester ethoxylate is FMEE 24-09 or FMEE 68-15. Others are the same as in the first or second embodiment.

[0020] Fatty acid methyl ester ethoxylate (FMEE) is a low-foaming non-ionic surfactant with excellent cleaning performance, especially strong dispersibility, and can effectively prevent redeposition of dirt during the cleaning process. It is suitable for Grease and wax cleaning. Purchased from China Light Daily Chemical Technology Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decontamination rate | aaaaa | aaaaa |

| decontamination rate | aaaaa | aaaaa |

| decontamination rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com