Environment-friendly water-soluble cutting fluid for magnesium alloy cutting

An environmentally friendly, cutting technology, applied in the direction of lubricating composition, etc., can solve the problem of poor corrosion resistance of magnesium and magnesium alloys, achieve the effect of good corrosion resistance of magnesium alloys, reduce scrap rate and prolong tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

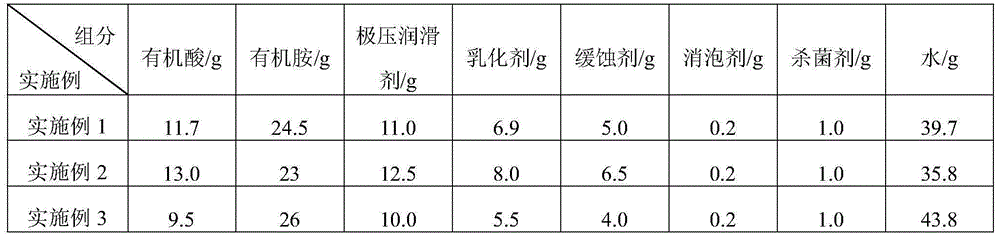

[0018] An environment-friendly water-soluble cutting fluid for magnesium alloy cutting, the composition and the amount of various components of the magnesium alloy cutting fluid can be:

[0019] ① 5-20g organic acid, 15-30g organic amine, 5-16g lubricant, 3-11g emulsifier, 1-6g corrosion inhibitor, 0.1-0.5g defoamer, 0.1-3.5g Fungicide and 15-70g of water.

[0020] ② 5-20g organic acid, 15-30g organic amine, 5-16g lubricant, 3-11g emulsifier, 1-6g corrosion inhibitor, 0.1-0.5g defoamer, 0.1-3.5g Fungicide and 15-70g of water.

[0021] ③ 10-15g organic acid, 20-25g organic amine, 8-13g lubricant, 5-8g emulsifier, 2-4g corrosion inhibitor, 0.2-0.3g defoamer, 0.8-1.5g Fungicide and 30-50g of water.

[0022] ④ 10-15g organic acid, 20-25g organic amine, 8-13g lubricant, 5-8g emulsifier, 2-4g corrosion inhibitor, 0.2-0.3g defoamer, 0.8-1.5g Fungicide and 30-50g of water.

[0023] ⑤ 10-15g organic acid, 20-25g organic amine, 8-13g lubricant, 5-8g emulsifier, 2-4g corrosion inhib...

Embodiment 2

[0026] According to the embodiments of the present invention, the specific type of organic acid is not particularly limited, and the organic acids in ①~⑥ in Example 1 include tricarboxylic acid, undecanedibasic acid, sebacic acid, One or more mixtures of neodecanoic acid and dimer acid, this organic acid can significantly improve the rust resistance of magnesium alloy cutting fluid. For example, the organic acid can be: ① tricarboxylic acid; ② undecanoic acid; ③ sebacic acid; ④ neodecanoic acid; ⑤ dimer acid; ⑥ tricarboxylic acid and undecanoic acid; ⑦Undecanoic acid and sebacic acid; ⑧Sebacic acid and neodecanoic acid; ⑨Undecanoic acid, sebacic acid and neodecanoic acid; ⑩Tricarboxylic acid, undecanoic acid, Sebacic acid, neodecanoic acid, and dimer acid. The tricarboxylic acid is preferably an organic heterocyclic tricarboxylic acid, and the dimer acid is preferably cyclocarboxypropyl oleic acid.

Embodiment 3

[0028] The organic amines in ①~⑥ in Example 1 can be triethanolamine, monoethanolamine, 2-cyclohexyl-diethanolamine, diglycolamine, isopropanolamine and 2-amino-2-methyl- One or more mixtures of 1-propanol, the reasonable use of this organic amine meets the performance requirements and environmental protection requirements of water-soluble cutting fluid, and has good pH stability, which is conducive to maintaining its long-term service life; For example: the organic amine can be: ① triethanolamine; ② monoethanolamine; ③ 2-cyclohexyl-diethanolamine; ④ diglycolamine; ⑤ isopropanolamine; ⑥ 2-amino-2-methyl-1-propanol; ⑦Isopropanolamine and 2-amino-2-methyl-1-propanol; ⑧Diethylene glycol amine and isopropanolamine; ⑨Triethanolamine and monoethanolamine; ⑩Triethanolamine, monoethanolamine, diglycolamine, Isopropanolamine and 2-amino-2-methyl-1-propanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com