Preparation method of nonionic-anionic compound type surfactant and application thereof

A surfactant and anion technology, applied in the preparation of carboxylate, chemical instruments and methods, drilling composition, etc., can solve the problem of no patent application paper report, etc., to achieve improved oil recovery and excellent performance , the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

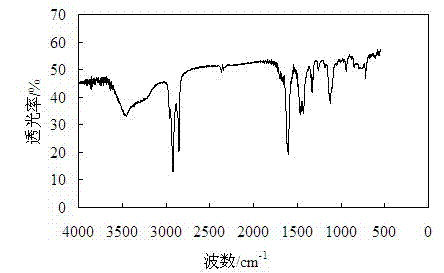

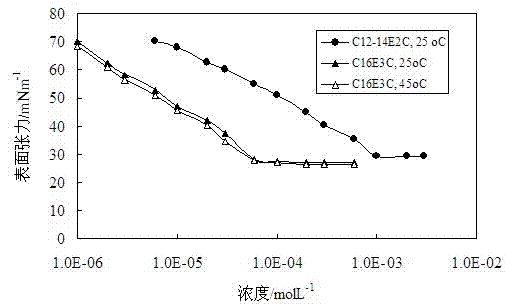

[0026] Coco alcohol polyoxyethylene ether (2) carboxylate (C 12-14 E. 2 C) Preparation: Put 20 g of natural coconut oil alcohol polyoxyethylene ether (2) (China Light Chemical Co., Ltd.) into a 250 mL glass reactor, take chloroacetic acid: alcohol ether molar ratio is 1.1: 1, first add Half of the chloroacetic acid was stirred and mixed, and the temperature was raised to 55°C. According to the NaOH: chloroacetic acid molar ratio of 2.5: 1 to determine the amount of solid NaOH added, first add half of the NaOH, react at 55 ° C for 0.5 hours, then add the other half of the chloroacetic acid and solid sodium hydroxide, continue the reaction 5-6 Hour. After the reaction is completed, the product is heated and dissolved in absolute ethanol, and the insoluble inorganic salt is removed by filtration. After the filtrate was further cooled and left to stand, the alcohol ether carboxylate was precipitated, filtered with suction, and the filter cake was vacuum-dried at 70°C to obtain ...

Embodiment 2

[0030] Cetyl alcohol polyoxyethylene ether (3) carboxylate (C 16 E. 3 C) Preparation: Add cetyl alcohol (analytical grade, Aladdin) to an average of 3 mol of ethylene oxide under base-catalyzed conditions to obtain cetyl alcohol polyoxyethylene ether (3). Put 20g of the alcohol ether into a 250 mL glass reactor, heat and melt, determine the molar ratio of chloroacetic acid:alcohol ether is 1.1:1, first add half of the chloroacetic acid, stir and mix, according to the molar ratio of NaOH:chloroacetic acid is 2.5:1 Determine the amount of solid NaOH added, add half of it first, react at 60°C for 0.5 hours, then add the other half of chloroacetic acid and solid sodium hydroxide, and continue the reaction for 5-6 hours. After the reaction is completed, the product is heated and dissolved in absolute ethanol, and the insoluble inorganic salt is removed by filtration. After the filtrate was further cooled and left to stand, the alcohol ether carboxylate was precipitated, filtered ...

Embodiment 3

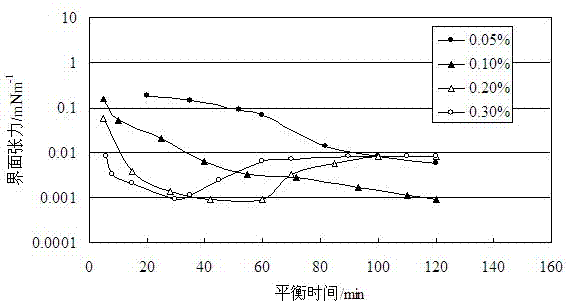

[0034] Coco alcohol polyoxyethylene ether (2) carboxylate (C) prepared by utilizing embodiment 1 12-14 E. 2 C) It is used to reduce the crude oil / formation water interfacial tension of Daqing No. 4 Plant under alkali-free conditions: the C 12-14 E. 2 C is compounded with carboxy betaine. The carboxy betaine used is produced by Rhodia Feixiang Chemical Co., Ltd. or synthesized by carboxymethylation with tertiary amine produced by Rhodia Feixiang Chemical Co., Ltd. The mixed surfactant is dissolved in Daqing Four Plant formation water, the total concentration (mass fraction) is 0.05%~0.3%, of which C in the mixed surfactant 12-14 E. 2 C mole fraction 0.20. 1000 mg / L polymer (polyacrylamide, molecular weight: 25 million) was pre-dissolved in formation water, and the interfacial tension of crude oil from Daqing No. Figure 5 shown. It can be seen that within the concentration range of determination, the equilibrium interfacial tension (120 min) reaches 10 -3 On the order o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com