Method of using microcrystalline graphite to prepare expanded microcrystalline graphite

A microcrystalline graphite, graphite expansion technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low expansion ratio of expanded graphite, poor effect of expanded graphite, and high sulfur content in products. Guarantee the effect of intercalation, improve the peeling rate and the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

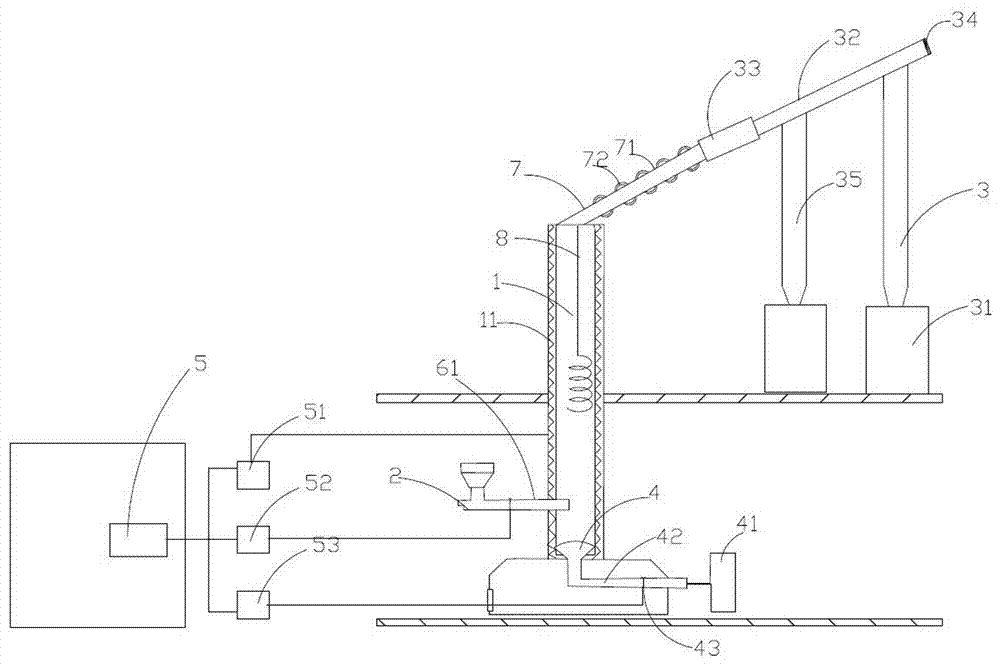

[0035] The method of the present invention for preparing expanded microcrystalline graphite material using microcrystalline graphite includes the following steps: a graphite expansion furnace is included, and a high temperature expansion method is adopted, including the following steps:

[0036] S1. Take the microcrystalline graphite raw material with 70% carbon content, crush and grind it to a particle size of 300 mesh microcrystalline graphite powder;

[0037] S2. Place the microcrystalline graphite powder obtained in step S1 with perchloric acid and potassium permanganate in a reaction device for the first chemical intercalation treatment to obtain an acidic suspension of expandable microcrystalline graphite. The acidic suspension is filtered, and the filtrate is retained for later use. Among them, the specific steps of the first chemical intercalation are: S21. Mix perchloric acid and microcrystalline graphite powder at a liquid-to-solid ratio of 10:1L / Kg and stir evenly; S22. ...

Embodiment 2

[0042] The steps of this embodiment are basically the same as those of embodiment 1, and the differences are:

[0043] S1. Take the microcrystalline graphite raw material with 70% carbon content, crush and grind it to a particle size of 300 mesh microcrystalline graphite powder;

[0044] S2. Place the microcrystalline graphite powder obtained in step S1 with perchloric acid and potassium permanganate in a reaction device for the first chemical intercalation treatment to obtain an acidic suspension of expandable microcrystalline graphite. The acidic suspension is filtered, and the filtrate is retained for later use. The specific steps of the first chemical intercalation are: S21. Mix perchloric acid and microcrystalline graphite powder at a liquid-to-solid ratio of 15:1L / Kg and stir evenly; S22. Add the strong oxidant according to the mass ratio of the microcrystalline graphite powder to the strong oxidant of 4:1. After stirring evenly at room temperature, the temperature is raised ...

Embodiment 3

[0048] The steps of this embodiment are basically the same as those of embodiment 1, and the differences are:

[0049] S1. Take the raw material of microcrystalline graphite with a carbon content of 75%, crush and grind it to a particle size of 350 mesh microcrystalline graphite powder;

[0050] S2. Place the microcrystalline graphite powder obtained in step S1 with perchloric acid and potassium permanganate in a reaction device for the first chemical intercalation treatment to obtain an acidic suspension of expandable microcrystalline graphite. The acidic suspension is filtered, and the filtrate is retained for later use. The specific steps for the first chemical intercalation are: S21. Mix perchloric acid and microcrystalline graphite powder at a liquid-solid ratio of 20:1L / Kg and stir evenly; S22. Add the strong oxidant according to the mass ratio of the microcrystalline graphite powder to the strong oxidant of 6:1, stir evenly at room temperature, and then heat to 50℃ and conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution range | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com