Method used for preparing lightweight ceramsite from sludge and copper slag

A technology of lightweight ceramsite and sludge ceramsite, which is applied in the field of non-metallic materials, can solve the problems of complex iron, low utilization rate of copper slag resources, waste of resources, etc., and achieve high economic value, efficient utilization, and improved feasibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

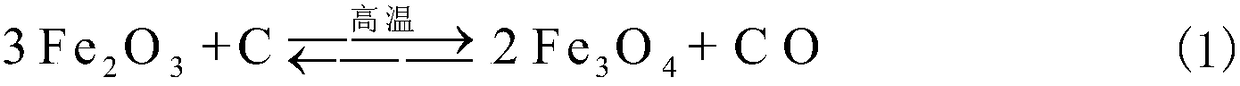

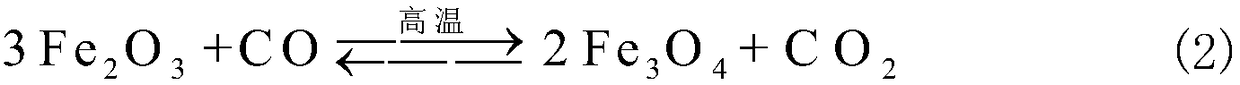

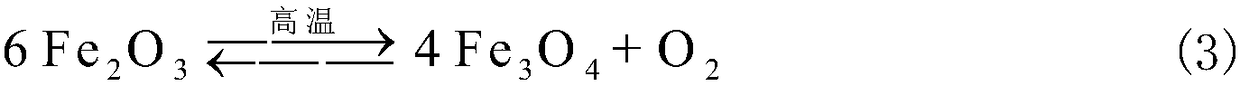

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, domestic sludge with a water content of 30% and copper slag micropowder with an iron content of 35% and a particle size of -0.074mm and accounting for 80% are mixed and stirred according to the mass fraction of dry material 75:25. Refining the mud to make it have a plasticity coefficient of 9, and then molding it into raw meal balls with a diameter of 6mm to 8mm through a granulator, and then drying the raw meal balls; placing the dried raw meal balls in a high-temperature furnace to Preheat at a preheating rate of 10°C / min to 450°C and hold for 5 minutes; then roast at a firing rate of 10°C / min, and hold for 15 minutes after firing to 1120°C; remove the sintered balls from the high-temperature furnace Take it out and let it cool down to room temperature under natural conditions. After testing, the bulk density of the sludge copper slag ceramsite product is 430kg / m 3 .

Embodiment 2

[0035] Firstly, domestic sludge with a water content of 43% and copper slag micropowder with an iron content of 33.6% and a particle size of -0.074mm and accounting for 85% are mixed and stirred according to the mass fraction of dry material 72:28. clay, so that the plasticity coefficient is 8.5, and then molded into raw meal balls with a diameter of 7mm to 9mm by a granulator, and then the raw meal balls are dried; the dried raw meal balls are placed in a high-temperature furnace, Preheat at a preheating rate of ℃ / min and raise the temperature to 500°C and hold for 6 minutes; then roast at a firing rate of 8°C / min, and then hold for 18 minutes after roasting to 1100°C; take out the sintered balls after heat preservation from the high-temperature furnace , placed under natural conditions and naturally cooled to room temperature. After testing, the bulk density of the sludge copper slag ceramsite product is 360kg / m 3 .

Embodiment 3

[0037] Firstly, domestic sludge with a moisture content of 36% and copper slag micropowder with an iron content of 37.4% and a particle size of -0.074mm and accounting for 78% are mixed and stirred according to the mass fraction of dry material at 70:30, and the sludge is smelted by a mud refining machine. mud, so that the plasticity coefficient is 8, and then molded into raw meal balls with a diameter of 5mm to 7mm by a granulator, and then the raw meal balls are dried; the dried raw meal balls are placed in a high-temperature furnace, and the Preheat at a preheating rate of ℃ / min to 480°C and hold for 7 minutes; then roast at a firing rate of 12°C / min, and after roasting to 1080°C, hold for 13 minutes; take out the sintered balls after heat preservation from the high-temperature furnace , placed under natural conditions and naturally cooled to room temperature. After testing, the bulk density of the sludge copper slag ceramsite product is 510kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com