High-performance water swellable rubber and preparation method thereof

A water-swellable rubber, high-performance technology, applied in the field of rubber products, can solve problems such as hindering the use range of water-swelling rubber, restricting the development of water-swelling rubber, and decreasing mechanical properties, achieving controllable water-absorbing speed, mechanical properties and ion resistance. Strong, high expansion multiplier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Azide in-situ modified nitrile rubber (NBR) prepares water-swellable rubber

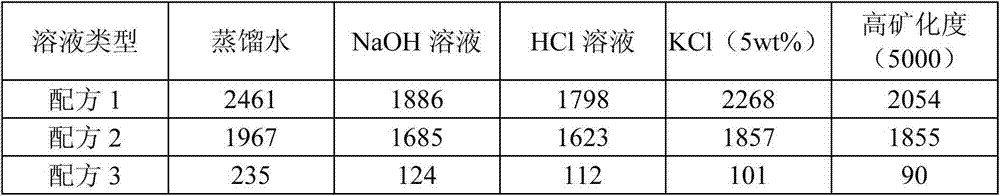

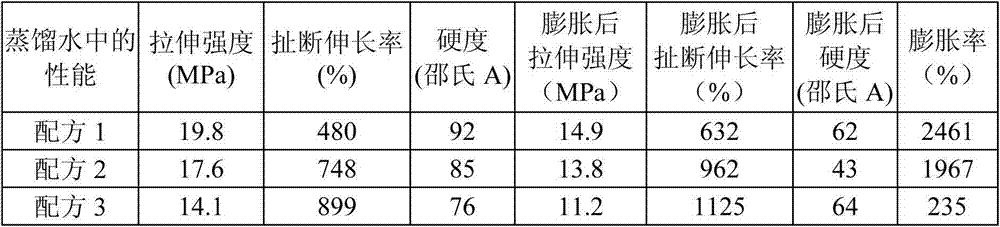

[0034]This embodiment provides the water-swellable rubber prepared with nitrile rubber (NBR) as the rubber matrix, as shown in Table 1, according to the raw materials and consumption (in parts by weight) of formula 1, formula 2 and formula 3 (comparative formula) Prepare water-swellable rubber, and its preparation method comprises the following steps:

[0035] At 25°C-50°C, first put the nitrile rubber into the open mill for plasticating for 5 minutes; then add sulfur, zinc oxide, stearic acid, anti-aging agent 4010, and water-absorbing resin (mainly composed of Sodium polyacrylate), white carbon black, azidotrimethylsilane (formulation 3 does not contain the azide coupling agent), and accelerator DM were mixed for 15-25 minutes to obtain a mixed rubber; at 160 ° C, Under the pressure of 15 MPa, the mixed rubber was vulcanized and molded in a flat vulcanizer, and the vulcanizatio...

Embodiment 2

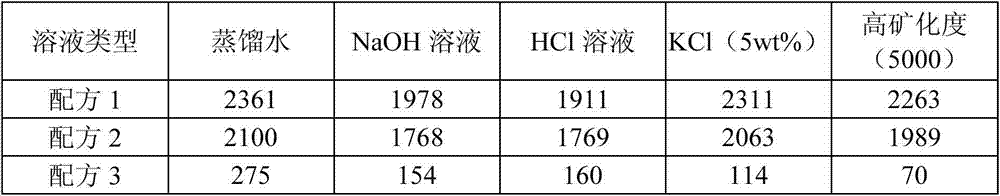

[0044] Example 2: Preparation of water-swellable rubber by in-situ modification of chloroprene rubber (CR) with azide

[0045] This embodiment provides the water-absorbing swelling rubber prepared with chloroprene rubber (CR) as the rubber matrix. Prepare water-swellable rubber, and its preparation method comprises the following steps:

[0046] Put the chloroprene rubber (CR) into the open mixer for 5 minutes at room temperature to 70°C; then add zinc oxide, stearic acid, and water-absorbing resin (mainly composed of sodium polyacrylate) into the open mixer in sequence , white carbon black, azidotrimethylsilane (prescription 3 does not contain the azide coupling agent), sulfur, accelerator CZ and accelerator TMTD were mixed for 15-25 minutes to obtain the compound glue; at 150 ℃, 15MPa, the mixed rubber was vulcanized and molded in a flat vulcanizer, and the vulcanization time was 45 minutes to prepare a standard 2mm thick water-swellable rubber test piece.

[0047] Table 4 ...

Embodiment 3

[0055] Example 3: Preparation of water-swellable rubber by in-situ modification of natural rubber (NR) with azide

[0056] This example provides water-swellable rubber prepared with natural rubber (NR) as the rubber matrix, as shown in Table 7, prepared according to the raw materials and dosage (in parts by weight) of formula 1, formula 2, and formula 3 (comparative formula) Water-swellable rubber, its preparation method comprises the following steps:

[0057] At 45-55°C, first put natural rubber (NR) into the open mill for plasticating for 5 minutes; then add zinc oxide, stearic acid, water-absorbing resin (mainly composed of sodium polyacrylate), and White carbon black, azidotrimethylsilane (formulation 3 does not contain the azide coupling agent), sulfur, accelerator CZ and accelerator TMTD are mixed for 15-25 minutes to obtain a rubber compound; , 15MPa, vulcanize and mold the mixed rubber in a flat vulcanizer, and the vulcanization time is 25 minutes to prepare a standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com