Drying and cooling integrated device for aromatic hydrocarbon adsorbent multi-chamber fluidized bed

A multi-chamber fluidized bed, drying and cooling technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of high power of the pressure blower, poor drying effect, poor fluidization stability, etc., to achieve High degree of integration, improved adsorbent production capacity, and reduced mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will also be described in further detail in conjunction with specific embodiments:

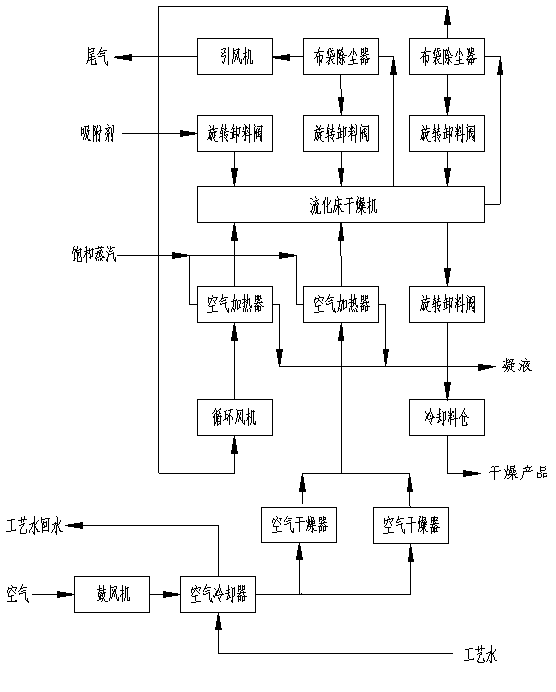

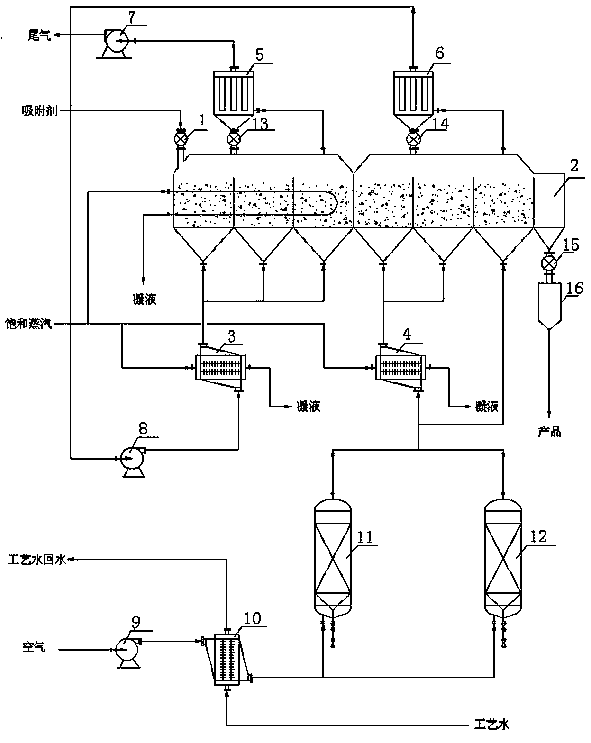

[0021] An aromatic hydrocarbon adsorbent semi-circulation internal heating multi-chamber fluidized bed deep drying and cooling integrated device, including fluidized bed 2, air heater 3 / 4, bag filter 5 / 6, blower 9, circulation fan 8, induced draft fan 7. Air cooler 10, air dryer 11 / 12, rotary unloading valve 13 / 14 / 15, cooling bin 16, the bottom of the fluidized bed is a porous sieve plate, and vertical baffles are respectively arranged above the sieve plate. The fluidized bed is sequentially divided into dehydration chamber, drying chamber, cooling chamber and unloading chamber from the direction of the feed inlet; the number of each chamber of the dehydration chamber, drying chamber, cooling chamber and unloading chamber is set to one or more, Specifically determined by the actual working conditions, figure 1 The baffle plate in the middle divides the fluidized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com