Tower mobile-bed reactor and its application

A moving bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as large differences in residence time, abnormal production, fluctuations in product quality, etc., and achieve residence time distribution Improve and solve the radial temperature gradient and reduce the effect of material backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

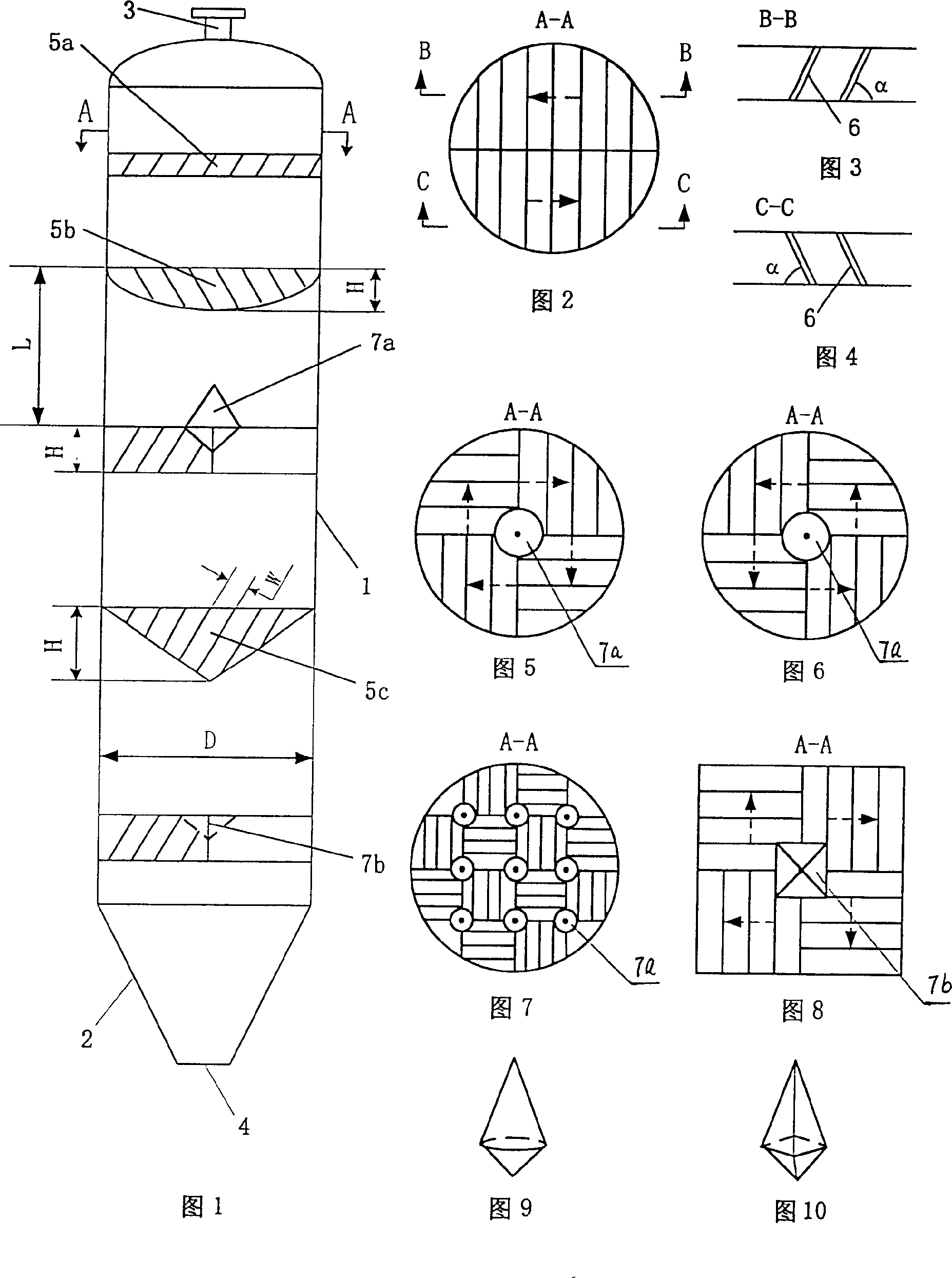

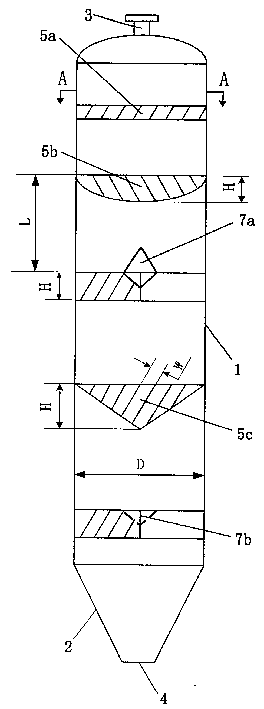

[0045] As shown in Figure 1, the tower type moving bed reactor, the tower body 1 is made into a cylinder, the inner diameter D is 3200mm, the height is 32m, the cone bottom 2 adopts a conventional design, and the upper and lower ends of the tower are respectively provided with openings 3 and 4. The interior of the tower body 1 is provided with 10 layers of internal members 5, and the distance L between each layer gradually increases from 500mm to 2000mm from top to bottom. The first two layers are all equipped with deflector sloping plates 6, each layer is divided into four areas, adjacent areas are arranged vertically to each other, and a conical diversion cone entity 7a or a concave downward virtual body is set at the center [7b]; The gap width W between the swash plates 6 in each area is 160-320mm, the central vertical height H of the swash plates 6 is 500-800mm, and the inclination angle α of the swash plates is 60 degrees. All the 6 layers in the middle are equipped with...

Embodiment 2

[0047]Using conventional PET polyester chips with an intrinsic viscosity of about 0.64dl / g as raw material, the tower-type moving bed reactor described in Example 1 is used for solid-state polycondensation to produce high-degree-of-polymerization polyester that can be used to manufacture beverage bottles. After drying, preheating, crystallization and other processes, the raw material slices enter the reactor through the opening 3 at the upper end of the reactor for solid phase polycondensation. The reaction temperature at this stage is 210°C, and the reaction system uses high-purity nitrogen as an inert atmosphere. Nitrogen gas enters from the bottom of the reactor and flows out from the opening 3, continuously flowing and displacing, taking away small molecules such as ethylene glycol and water generated by the solid-state polycondensation reaction. The nitrogen gas flowing out of the solid-phase polycondensation reaction system can be recycled after being purified. When wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com