A biomass pyrolysis production process with a multi-chamber fluidized bed reactor as the core

A fluidized bed reactor and biomass thermal cracking technology, which is applied in the fields of biofuels, petroleum industry, liquid hydrocarbon mixture preparation, etc. It can reduce the large-scale back-mixing phenomenon, improve the residence time distribution, and achieve the effect of continuous production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

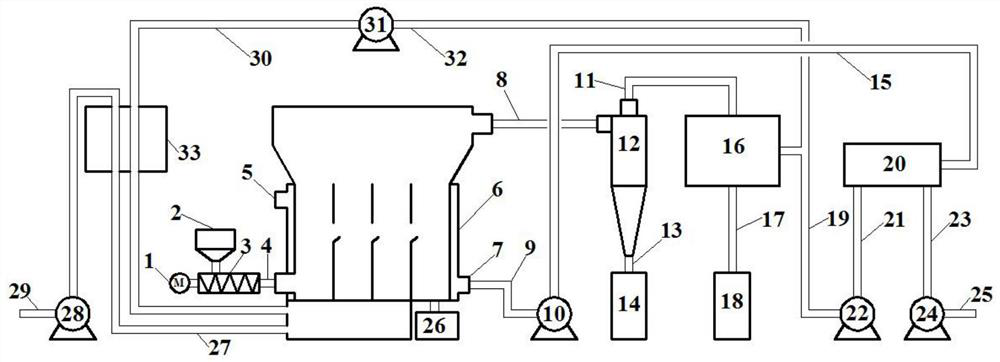

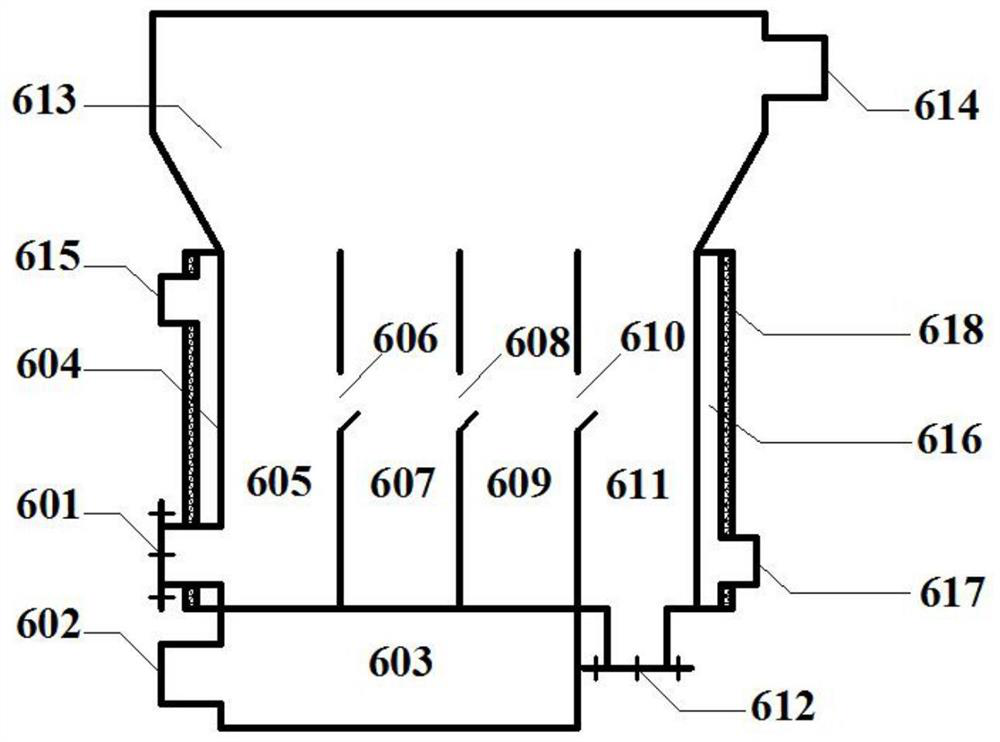

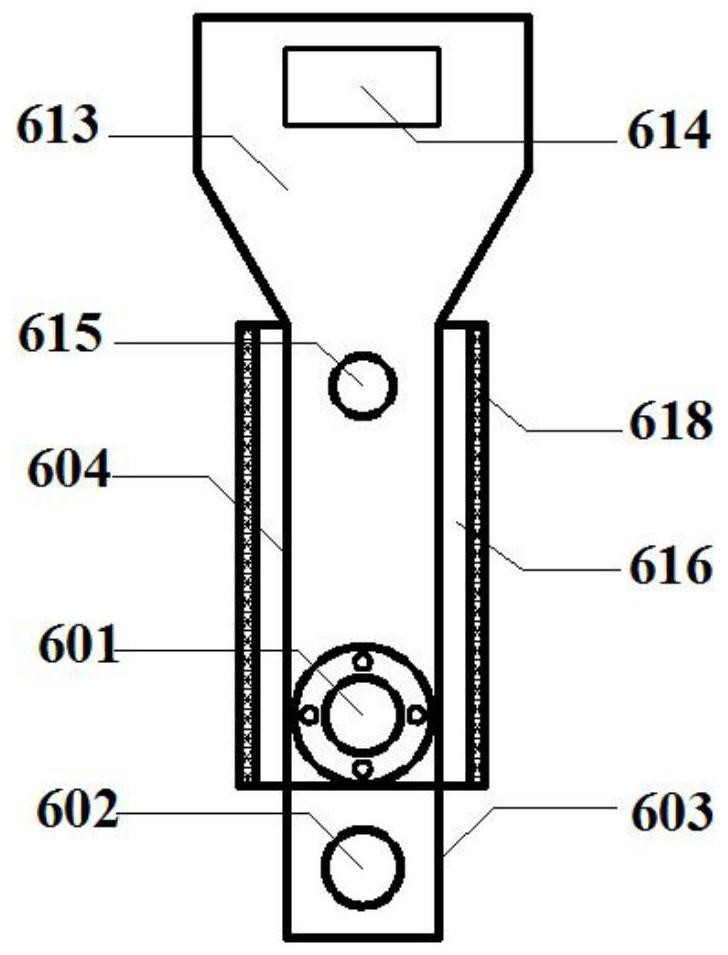

[0026] Continuous fast pyrolysis of wood pellets using a multi-chamber fluidized bed reactor. Wood pellets are continuously fed into the multi-chamber fluidized bed reactor by a screw feeder, where they are fluidized and rapidly pyrolyzed in the first three chambers. After the cracking is completed, the remaining solid residue is continuously drawn out of the reactor from the star unloader at the bottom of the unloading chamber. The generated pyrolysis gas is carried by the fluidization gas to quickly move out of the reactor and enter the subsequent gas-solid separation system and condensation system, effectively avoiding secondary cracking. The deflector at the opening is conducive to the sequential one-way flow of wood chips between adjacent chambers, and effectively inhibits the back-mixing of particles in the reactor. The multi-compartment structure makes the cracking process of wood chips artificially divided into three stages, improves the residence time distribution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com